Graphene processing device and method

A processing device and graphene technology, applied in the direction of workbench, manufacturing tools, etc., can solve the problems of large volume of high-purity graphite block, difficult lifting and erecting of tubular graphite, and difficult operation and processing, so as to reduce the difficulty of erection and increase the efficiency of erection , the effect of smooth motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

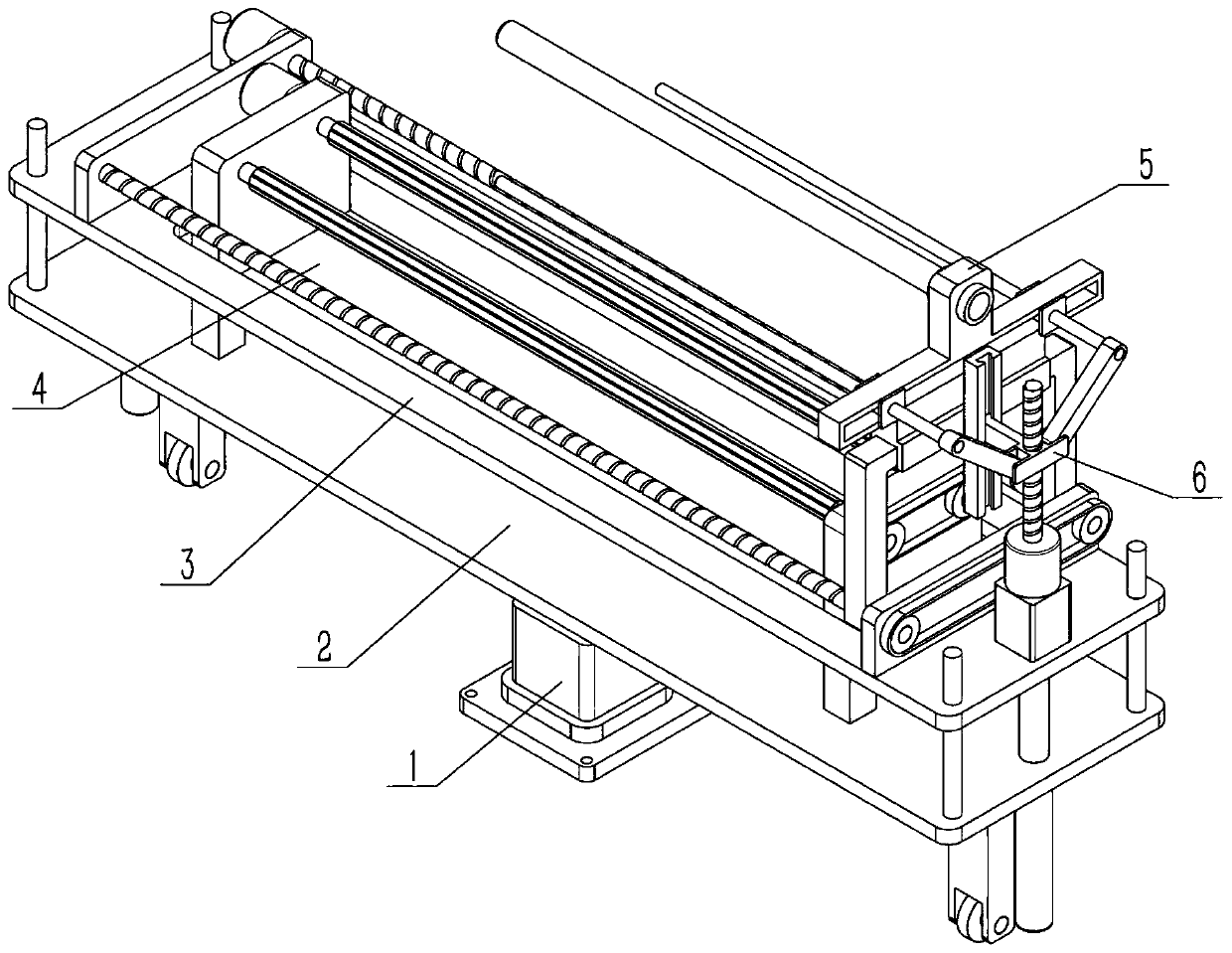

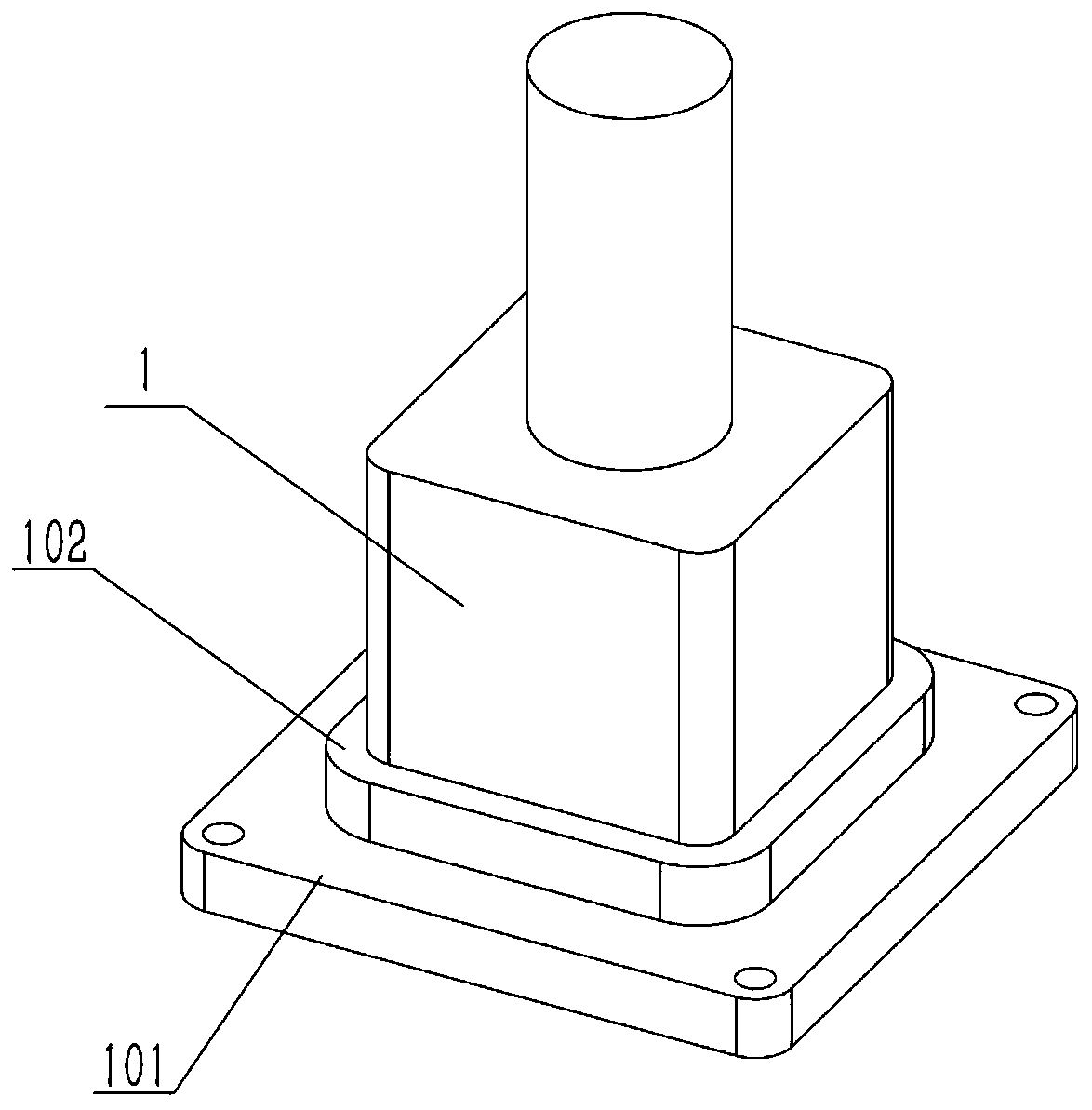

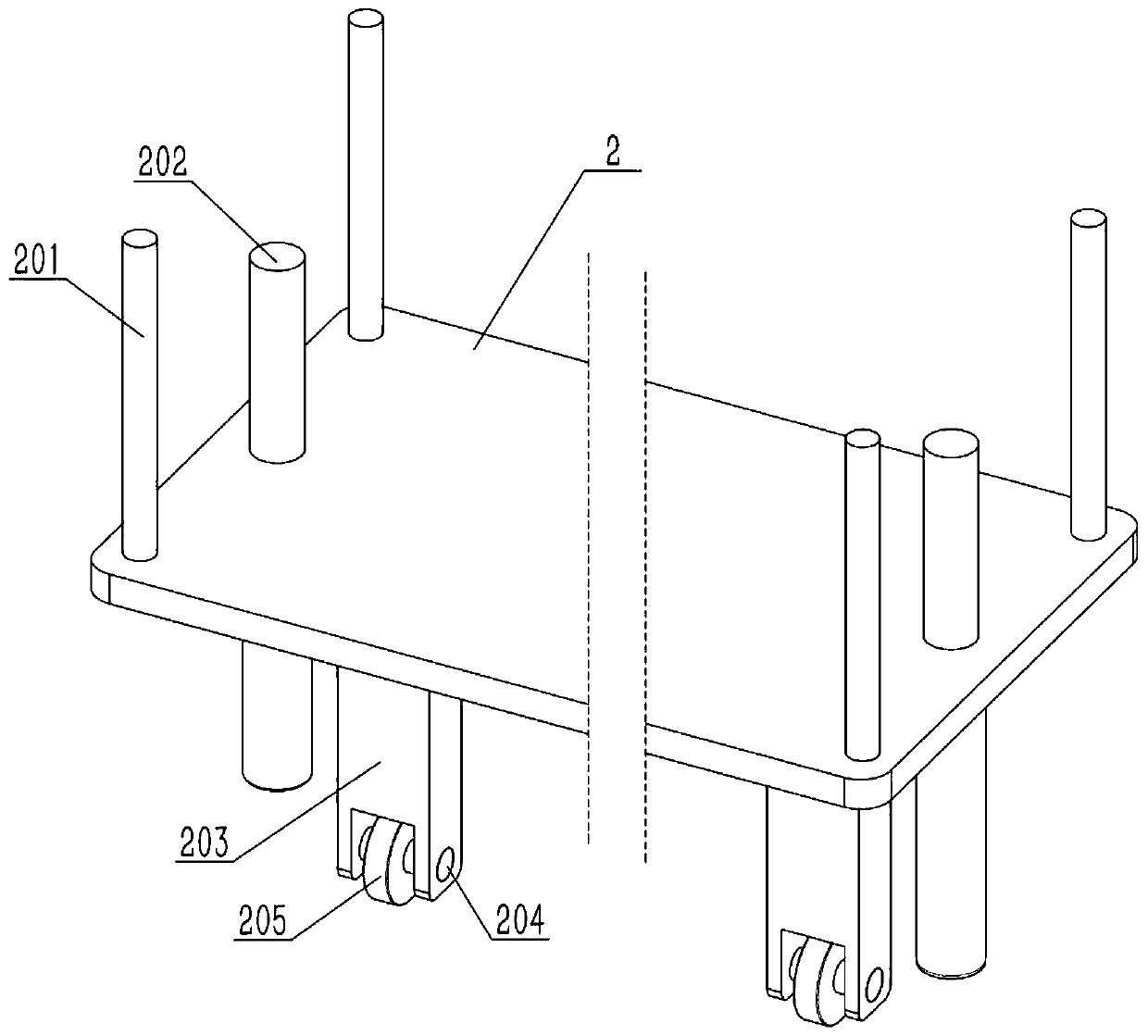

[0032] Such as Figure 1-7 As shown, a graphene processing device includes a bearing platform 4 and a shaft II 401, two shafts II 401 are symmetrically arranged, and the two ends of each shaft II 401 are rotatably connected to the two ends of the bearing platform 4, and the two shafts The plane level determined by the axis of II401. Use a lifting device such as a workshop crane to hang the large tubular graphene on the two shafts II 401, and use the two shafts II 401 to form line contact with the bottom of the tubular graphene, which is convenient for fixing it in combination with the self-weight of the tubular graphene. Two shafts Ⅱ401 are suitable for tubular graphene with a fixed cross-section of circular, triangular or quadrilateral cross-section, and tubular graphene with a triangular or quadrilateral cross-section requires a corner punch to be inserted between two shafts Ⅱ401 In between, it is convenient to process or detect each surface or each edge of the tubular grap...

specific Embodiment approach 2

[0034] Such as Figure 1-7 As shown, the graphene processing device also includes a pulley II 402, a transmission belt II 403 and a motor III 405. The same ends of the two shafts II 401 are respectively fixed to a pulley II 402, and the two pulleys II 402 are connected through a transmission belt. The motor III 405 The output shaft is fixedly connected to the other end of one of the shafts II 401 , and the motor III 405 is fixedly connected to the carrying platform 4 . Start the motor Ⅲ405, the output shaft of the motor Ⅲ405 drives the shaft Ⅱ 401 connected to it to rotate, and the shaft Ⅱ 401 drives the other shaft Ⅱ 401 to rotate synchronously with it through the synchronous transmission connection of the pulley Ⅱ 402, and then the two shafts Ⅱ 401 can turn, slightly Rotating the two shafts II 401 can drive the tubular graphene with a circular cross-section to rotate, which is convenient for inspection and processing of circular graphene at a fixed viewing angle. If the shaf...

specific Embodiment approach 3

[0036] Such as Figure 1-7As shown, the graphene processing device also includes a connecting frame 501 and a drag shaft 502, one end of the drag shaft 502 is rotatably connected to the upper end of the connecting frame 501, and the connecting frame 501 enables the drag shaft 502 to be carried out above the two shafts II 401. Moving left and right or up and down, the drag shaft 502 is located above the middle of the two shafts II 401 . The movement of the shaft II 401 can be used to place the circular graphene on the two shafts II 401 without using the hoisting device. Due to the problem of the viewing angle of the hoisting device or the volume of the hoisting device, or because the band-like flexible material is used to bind the pair during hoisting The round graphene is hoisted, which makes it difficult to place it accurately, and due to site constraints, it is not convenient for the crane to move frequently. It is more convenient to insert the round graphene through the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com