A processing device for the production of aluminum products with anti-oxidation function

A processing device and anti-oxidation technology, which is used in combination devices, welding protection devices, chemical instruments and methods, etc., can solve the impact of respiratory health of workers and the environment of the factory area, oxidation and blackening of aluminum pipe welding, affecting product quality, etc. problems, to achieve the effect of improving health and safety, improving accuracy, and improving indoor air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

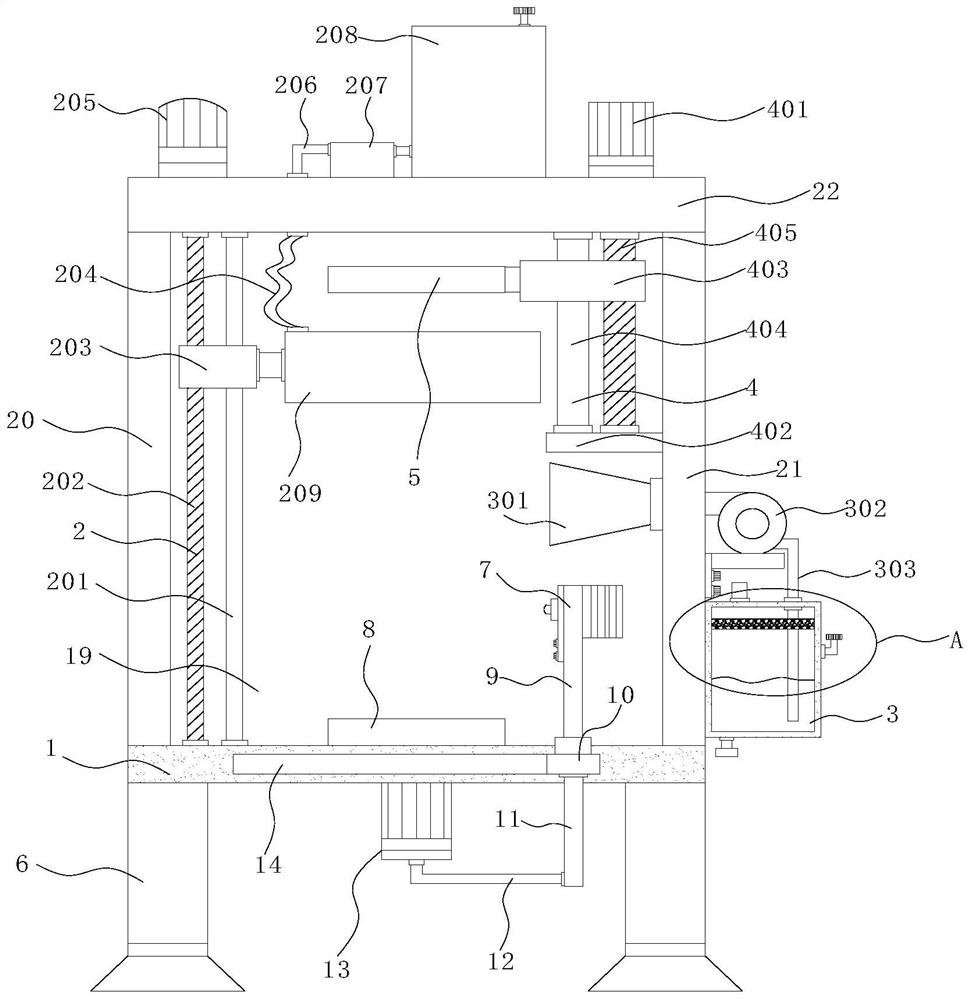

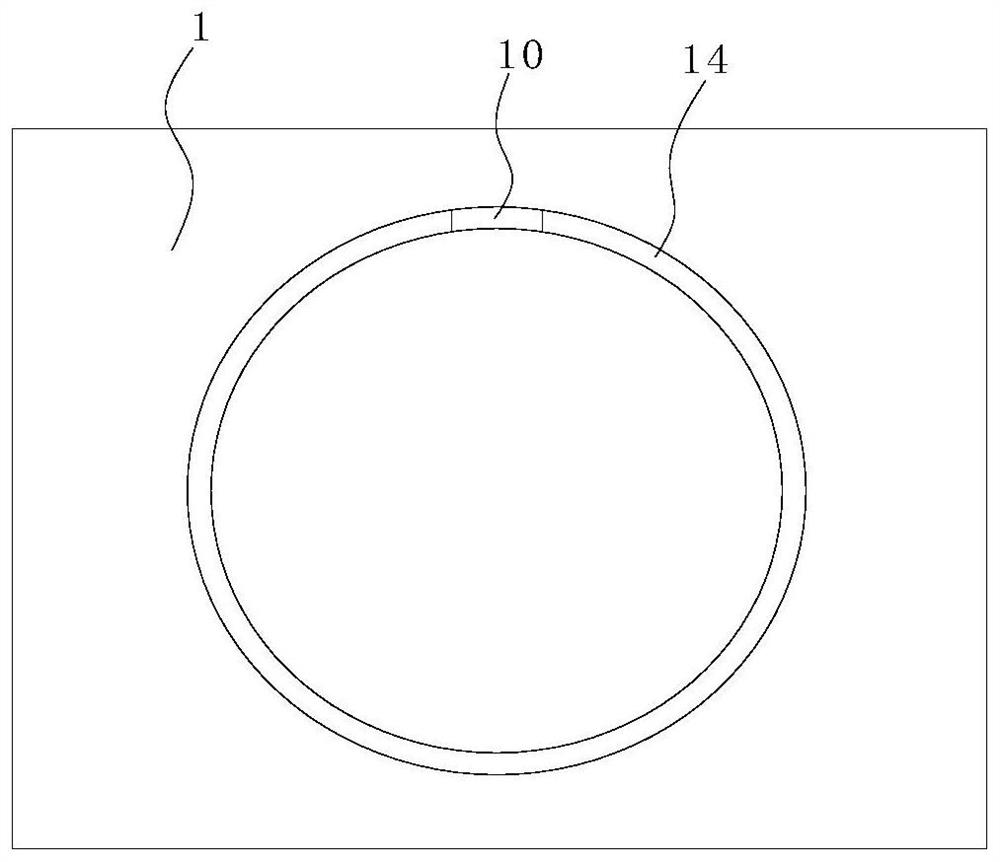

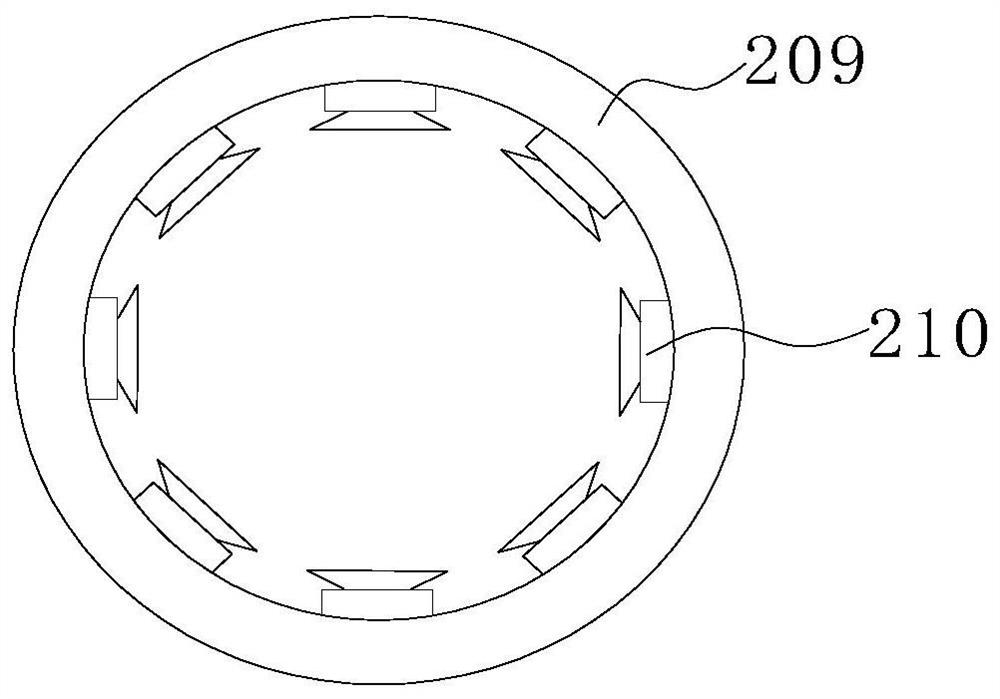

[0025] See Figure 1-6 The present invention provides a technical solution: an aluminum product manufacturing device having an oxidation function, including the bottom plate 1, the bottom plate 1 fixedly mounted with support leg 6, the number of support legs 6 is four, and its bottom The non-slip rubber base is provided, so that the stability can be effectively increased, the top of the bottom plate 1 is fixedly mounted, and the slide 14 is opened in the bottom plate 1, the chute 14 is planar, and the top of the chute 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com