Etching device for producing machine part

A technology for mechanical parts and engraving, which is applied in the field of engraving devices for the production of mechanical parts. It can solve problems such as inability to buffer, high initial force of engraving, and damage to the edge of the engraving knife, so as to facilitate installation and disassembly and improve the overall connection strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

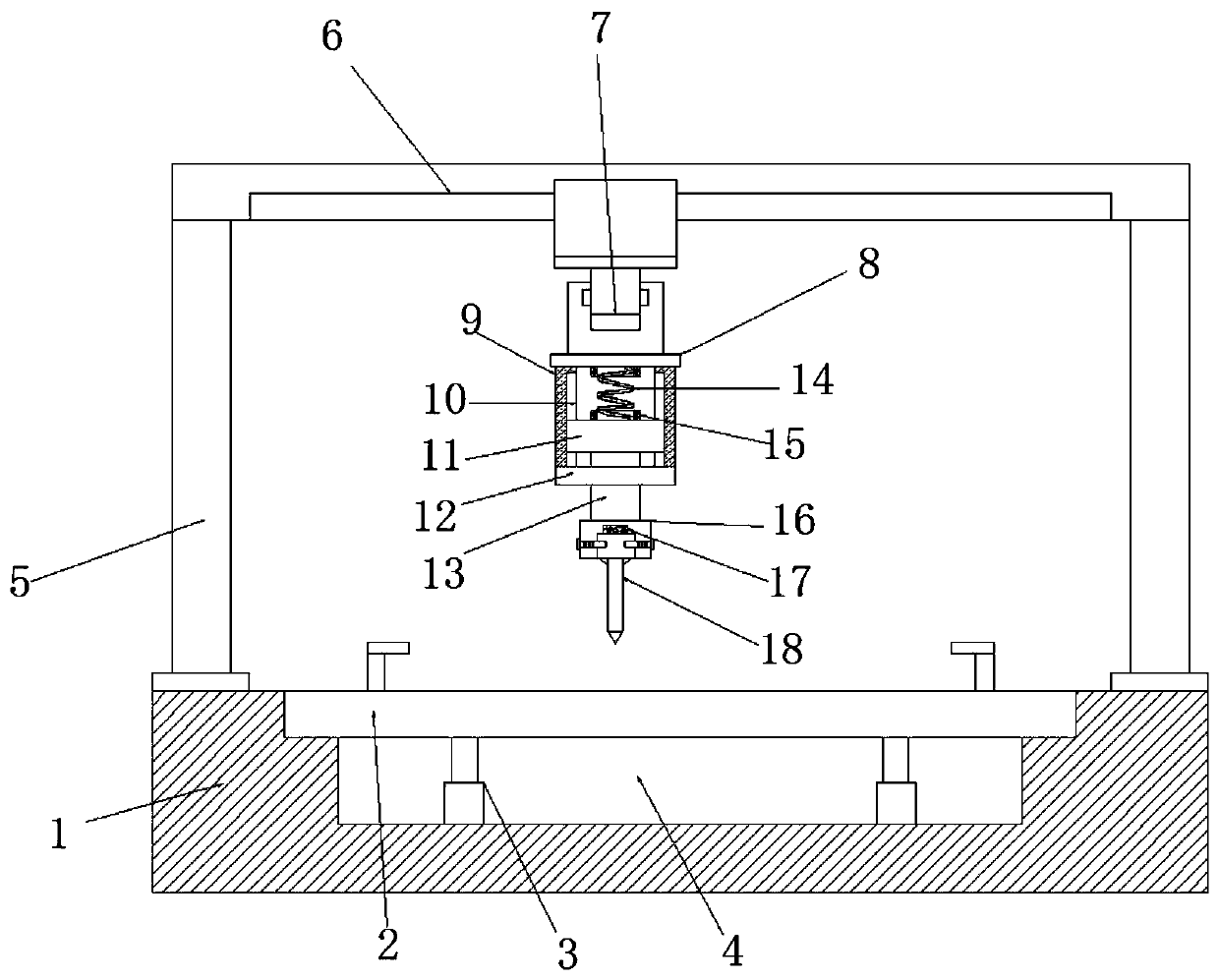

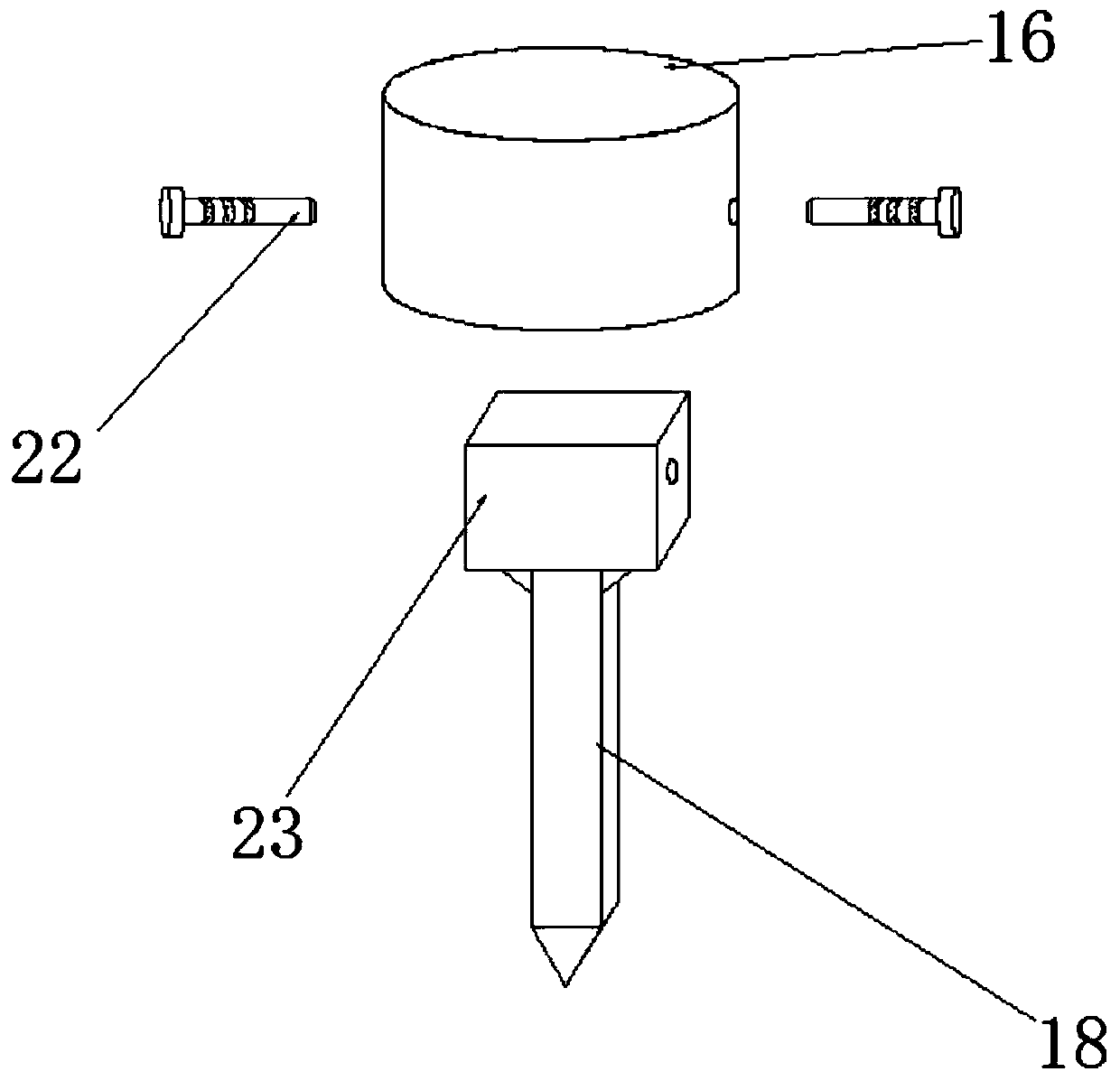

[0026] refer to Figure 1-3 , an engraving device for mechanical parts production, comprising a base 1, an installation cavity 4 is opened on the top of the base 1, and a storage mechanism is fixed on the installation cavity 4, support rods 5 are fixed on both sides of the top outer wall of the base 1, and The tops of the two support rods 5 are fixed with a drive mechanism, the bottom of the drive mechanism is fixed with a connecting plate 8, the two sides of the outer wall of the bottom of the connecting plate 8 are fixed with guide plates 9, and the bottom ends of the two guide plates 9 are fixed with the same base plate 12. A guide rod 13 is movably inserted, and the guide rod 13 is fixed with a slide block 11. One side of the two guide plates 9 is provided with a guide groove 10 that forms a sliding fit with the slide block 11. The top of the slide block 11 and the bottom of the connecting plate 8 are all fixed and limited The same spring 14 is fixed between the position r...

Embodiment 2

[0030] refer to Figure 4 , an engraving device for mechanical parts production. The difference between this embodiment and Embodiment 1 is that two screw rods 20 are threadedly inserted on the bottom plate 12, and the top of the screw rods 20 is fixed with an extrusion block 19 that contacts the outer wall of the bottom of the slider 11. , The bottom end of the screw rod 20 is fixed with a rotating block 21 .

[0031] The working principle of this embodiment: when the staff rotates the rotating block 21, the screw rod 20 moves upward, drives the extrusion block 19 to move upward, and then pushes the slider 11 to move upward, reduces the distance between the slider 11 and the connecting plate 8, and adjusts the spring The initial compression of 14 makes the adjustment of the initial extrusion force when the engraving knife 18 carries out the engraving work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com