A mechanochemical preparation method of a thyne-rich carbon material and its application in the adsorption of heavy metal ions in aqueous solution

A mechanochemical, carbon material technology, applied in chemical instruments and methods, other chemical processes, adsorbed water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

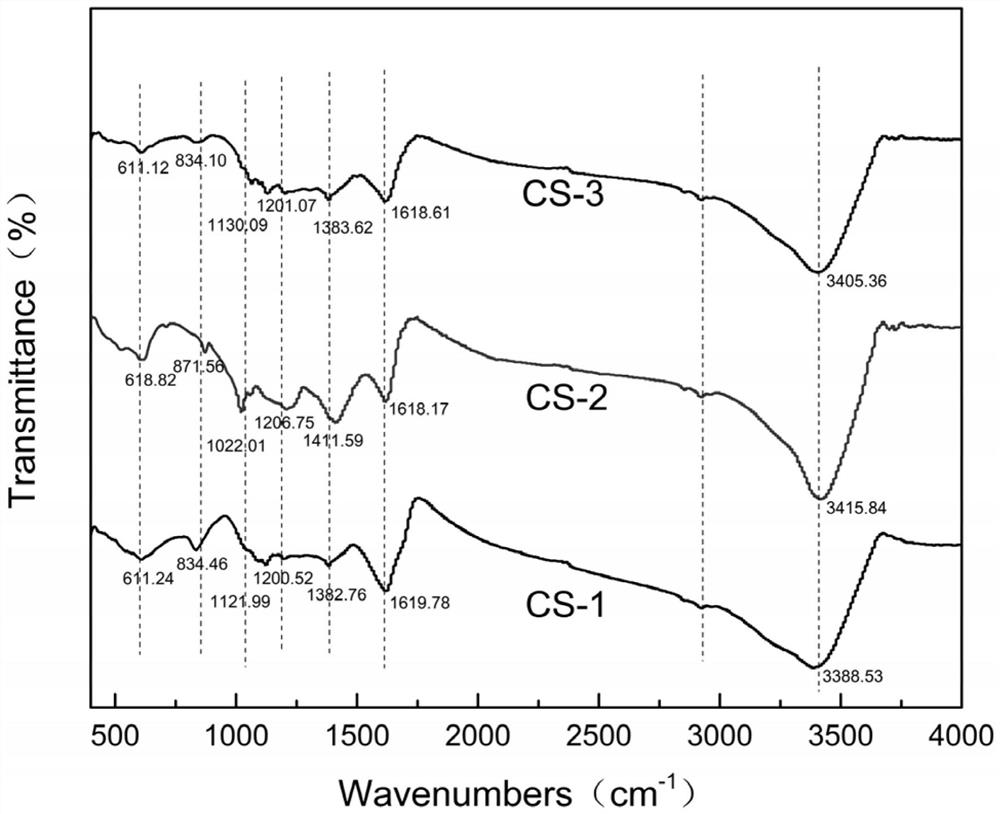

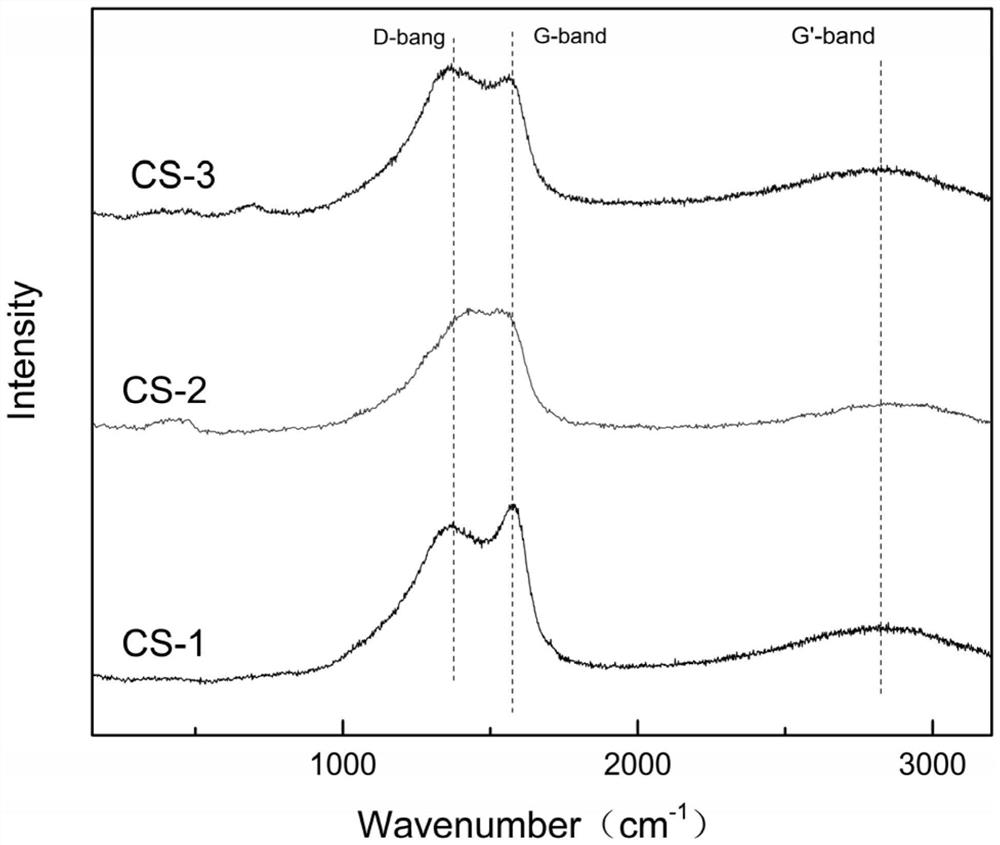

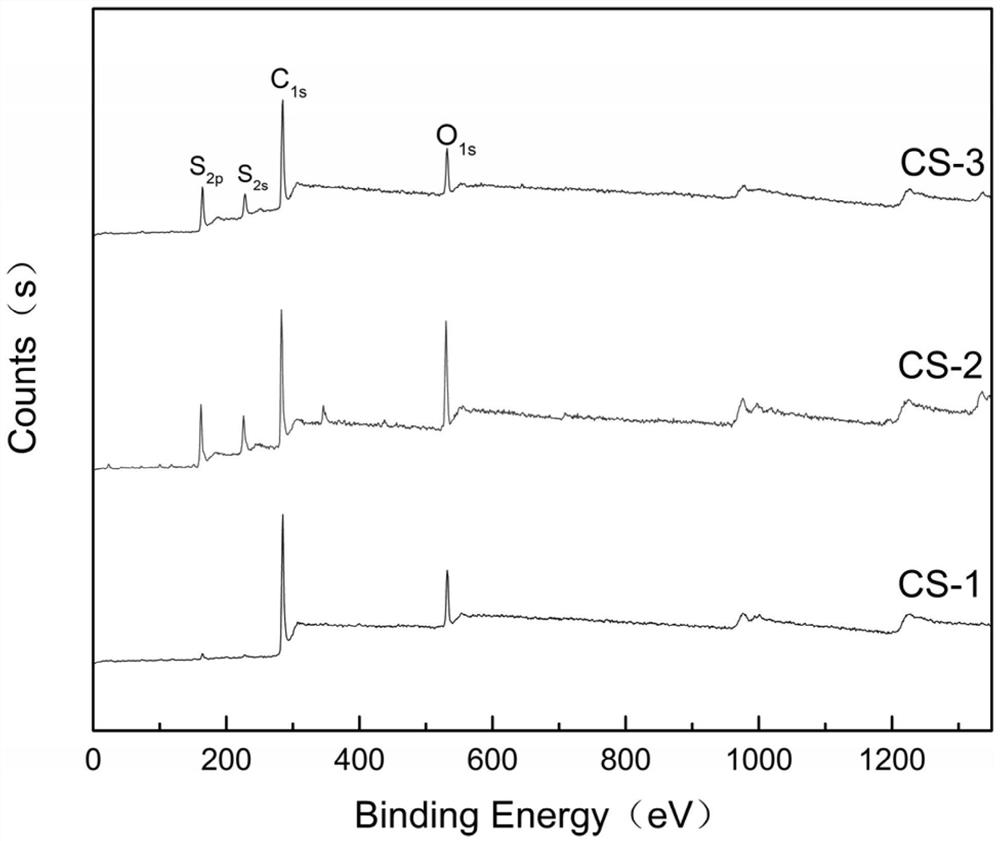

[0022] Weigh 4g of calcium carbide powder into a 250mL ball mill jar, add 2.37g of carbon disulfide liquid, seal it, and evacuate the ball mill jar. The ball mill jar was placed in a planetary ball mill, and ball milled at 600 rpm for 6 hours. In order to prevent the machine from overheating, the jacket water is used for cooling, and it is stopped for 10 minutes every 50 minutes of operation, so as to ensure that the temperature in the tank is below 60°C. After the reaction is finished, the ball mill tank is opened to obtain a black carbon material, and the impurity in the carbon material is removed by acid washing, water washing and ethanol washing, and the thionyl-rich carbon material of the present invention is obtained after drying.

[0023] Weigh 25 mg of the adsorbent (the thyne-rich carbon material described in this example), add it to 50 g of industrial wastewater with a mercury ion concentration of 500 ppm, and pH=5, ultrasonicate it for 10 minutes, and place it in a ...

Embodiment 2

[0027]Weigh 4g of calcium carbide powder into a 250mL ball mill jar, add 5.34g of carbon disulfide liquid at the same time, seal the ball mill jar, vacuumize it, put it in a planetary ball mill, and mill it at 600rpm for 6h. During the operation, in order to prevent the machine from overheating, a cooling water jacket is used to cool down, and it stops for 10 minutes every 50 minutes of operation. After the reaction is finished, the ball mill tank is opened to obtain a black carbon material, and impurities in the carbon material are removed after pickling, water washing and ethanol washing, and the thione-rich carbon material of the present invention is obtained by drying.

[0028] Weigh 25 mg of the adsorbent (the thyne-rich carbon material described in this example), add it to 50 g of industrial wastewater with a mercury ion concentration of 500 ppm, and pH=5, ultrasonicate it for 10 minutes, and place it in a constant temperature water bath at 25°C for 5 hours with magnetic ...

Embodiment 3

[0033] Weigh 4g of calcium carbide powder into a 250mL ball mill jar, add 10.68g of carbon disulfide liquid at the same time, seal the ball mill jar, vacuumize it, put it in a planetary ball mill, and mill it at 600rpm for 6h. In order to prevent the machine from overheating, use a cooling water jacket to cool down, and stop for 10 minutes every 50 minutes of operation. After the reaction is finished, the ball mill tank is opened to obtain a black carbon material, and impurities in the carbon material are removed after pickling, water washing and ethanol washing, and the thione-rich carbon material of the present invention is obtained by drying.

[0034] Weigh 25 mg of the adsorbent (the thyne-rich carbon material described in this example), add it to 50 g of industrial wastewater with a mercury ion concentration of 500 ppm, and pH=5, ultrasonicate it for 10 minutes, and place it in a constant temperature water bath at 25°C for 5 hours with magnetic stirring. It is measured th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com