Active coke adsorption tower and method for adsorbing and purifying flue gas by active coke

A technology of activated coke and adsorption tower, which is applied in the field of activated coke adsorption tower and activated coke adsorption and purification of flue gas, and can solve the problems of secondary pollution of ammonia and low adsorption capacity of activated coke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] This example is used to illustrate the method for purifying flue gas by activated coke adsorption of the present disclosure.

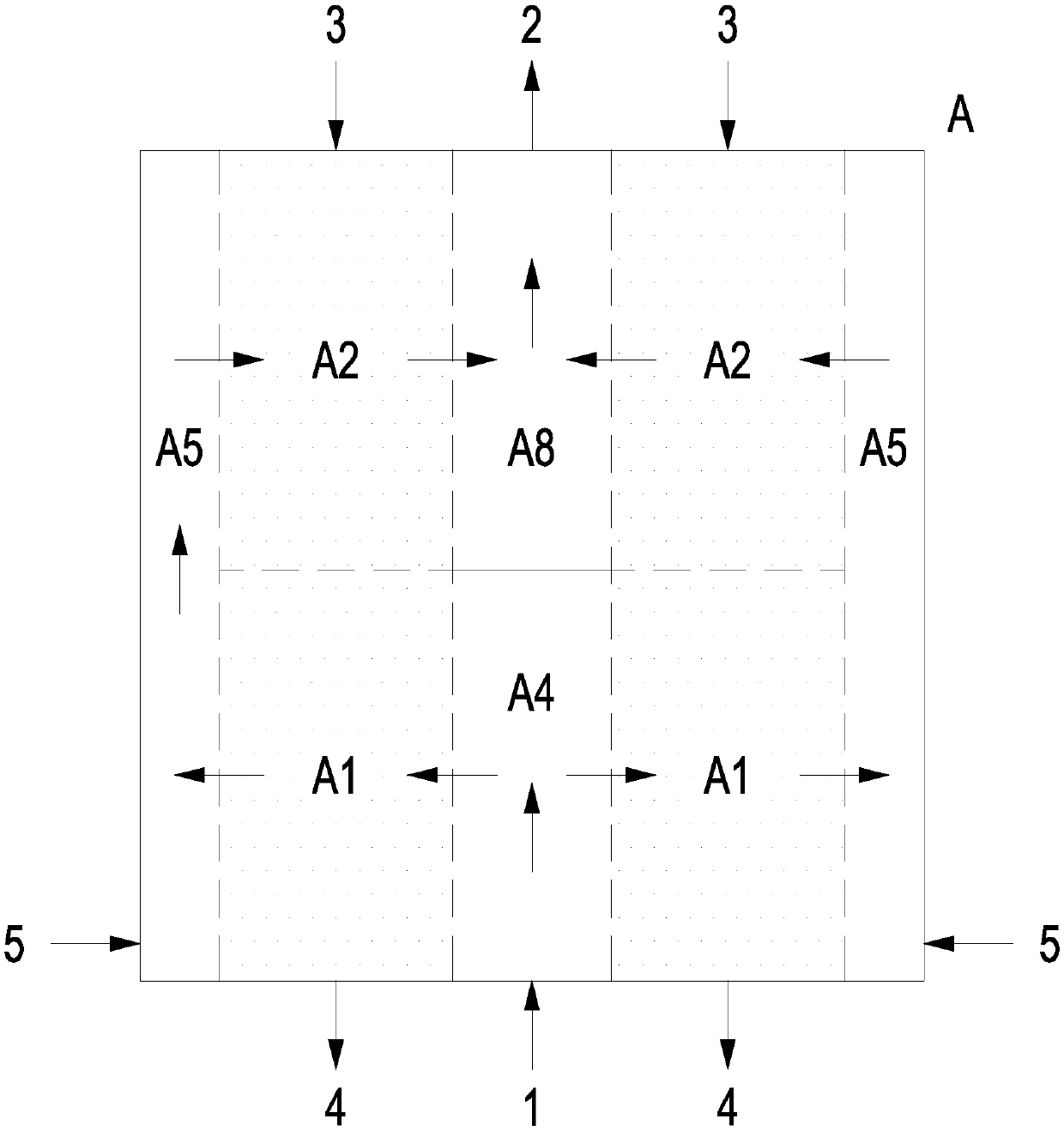

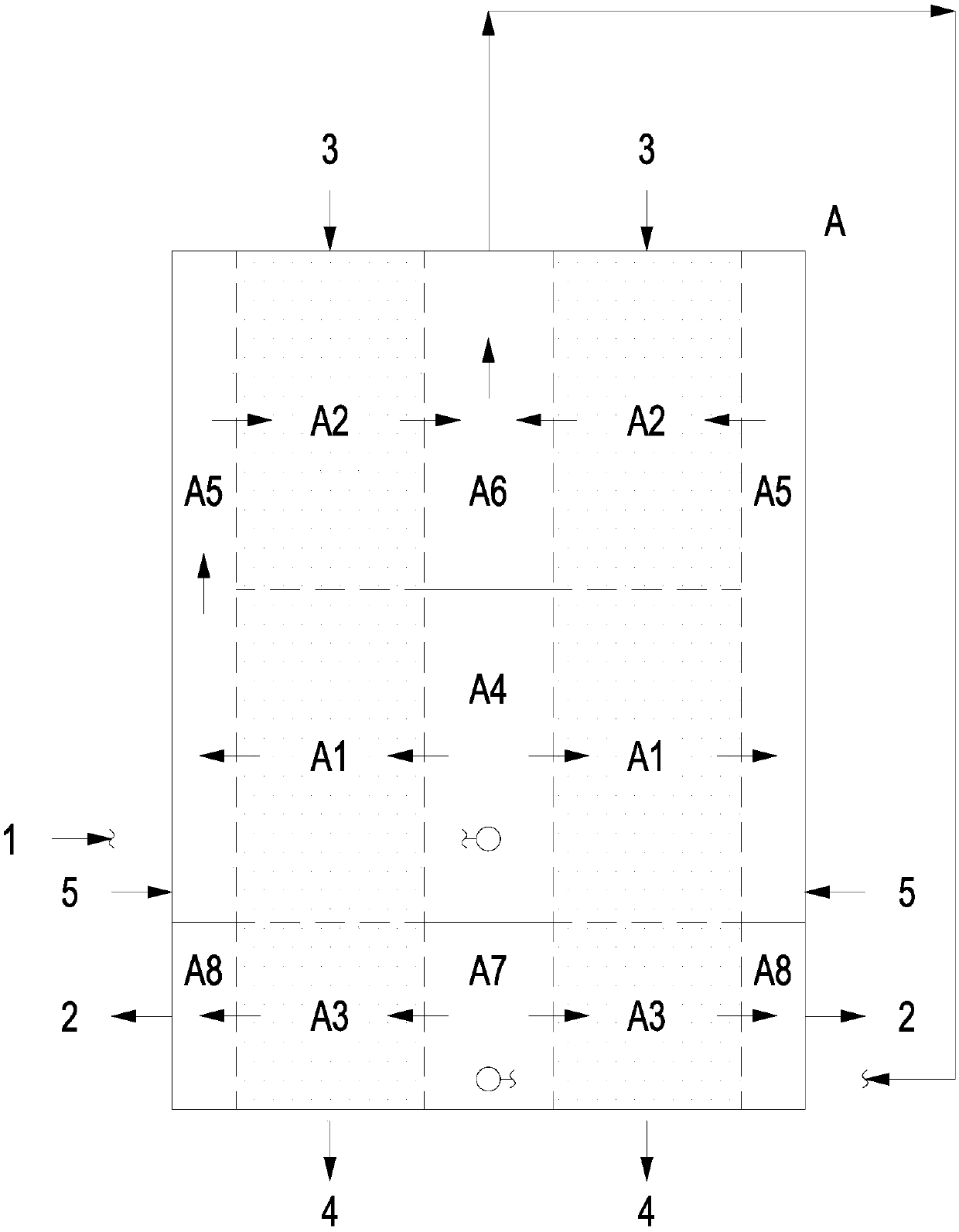

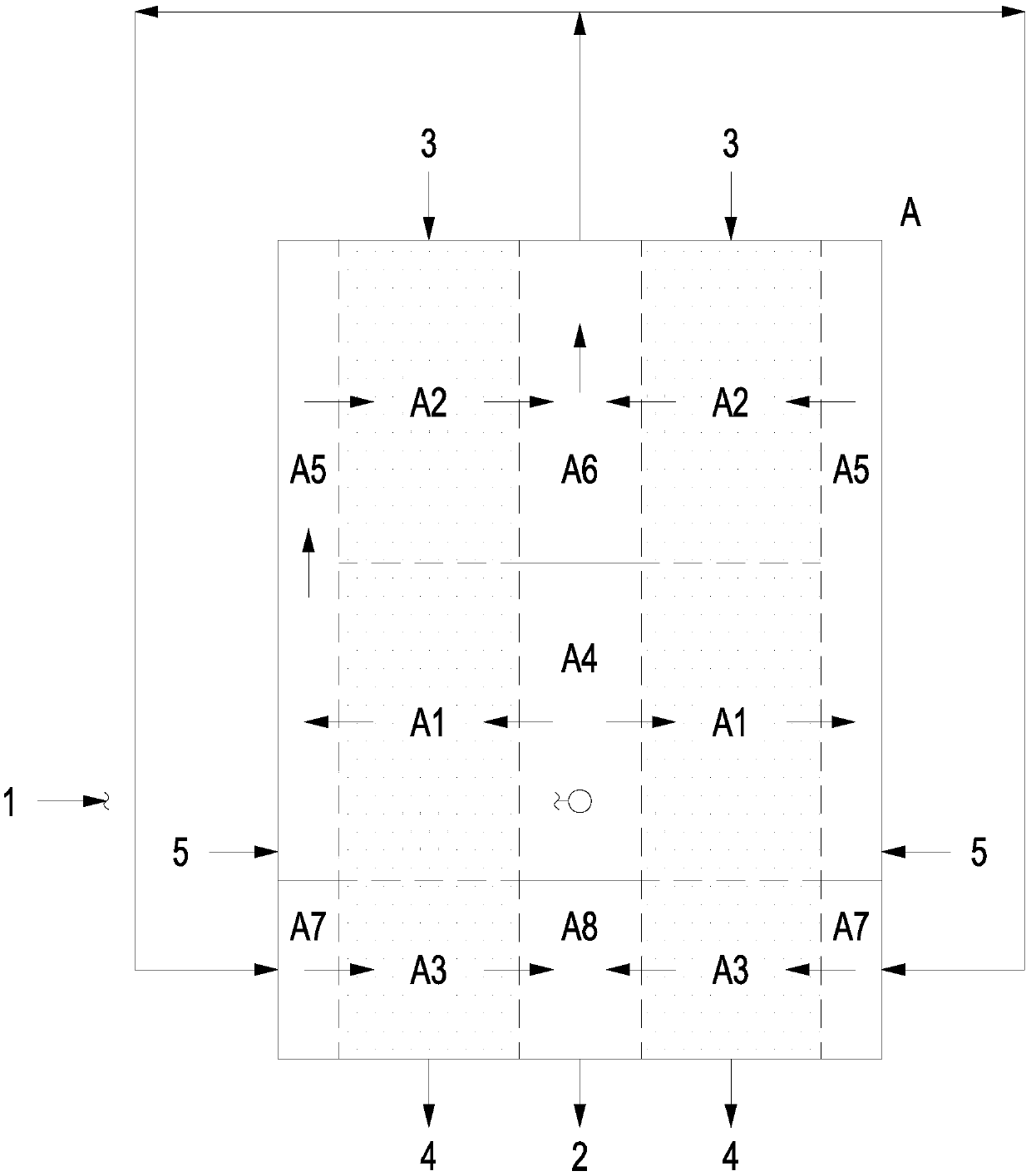

[0067] Such as figure 2 As shown, the adsorption tower adopts a three-stage cross-flow adsorption structure, and the flue gas 1 to be purified in the comparative example is used. From the upstream device, it first enters the inlet gas buffer A4 of the adsorption tower A, and then passes through the first-stage cross-flow adsorption bed A1 , cross-flow contact with activated coke to remove most of the SO in the flue gas 2 . The flue gas from the first-stage cross-flow adsorption bed A1 enters the first inter-stage gas buffer zone A5, where it is evenly mixed with the denitrification ammonia injection 5, and then enters the second-stage cross-flow adsorption bed A2, where it is mixed with the active coke cross-flow contact to remove the remaining SO 2 and NO X . The flue gas from the second-stage cross-flow adsorption bed layer A2 enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com