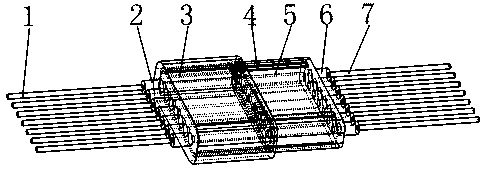

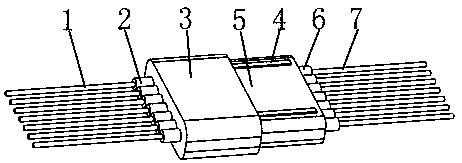

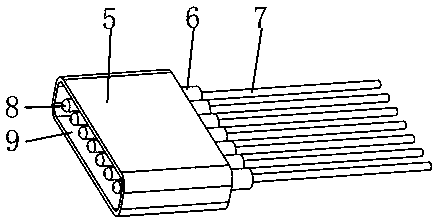

High-voltage wire plug connector for power industry

A technology in the high-voltage wire and electric power industry, which is applied in the direction of contact parts, electrical components, and parts of connection devices, etc. It can solve the problems of troublesome installation work for installation workers, difficult insertion and insertion of high-voltage wire connectors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0063] The specific implementation is as follows: when the first fixed shell 3 and the second fixed shell 5 are not installed, the second stop block 49 in the first fixed shell 3 and the second limit slot 50 are distributed oppositely, and the second leaf spring 47 It is in a compressed state; when the installer needs to connect the first fixed shell 3 and the second fixed shell 5 together, the installer at this time inserts the second fixed shell 5 into the first accommodation opened on the first fixed shell 3 In the cavity 12, when the displacement of the first rack 4 on the second fixed shell 5 inserted into the first receiving cavity 12 is large, the first rack 4 drives the second gear 23 to have a tendency to rotate, and the first square at this time 26 has a tendency to rotate under the drive of the first gear 22. When the first block 26 will be restricted by the second guide groove 35 opened on the second guide block 21, so that the first block 26 will be subject to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com