Stainless steel square welded pipe welding seam eddy current online detection device

A detection device, stainless steel technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., to achieve the effect of ensuring consistency, ensuring reliability, and quick adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

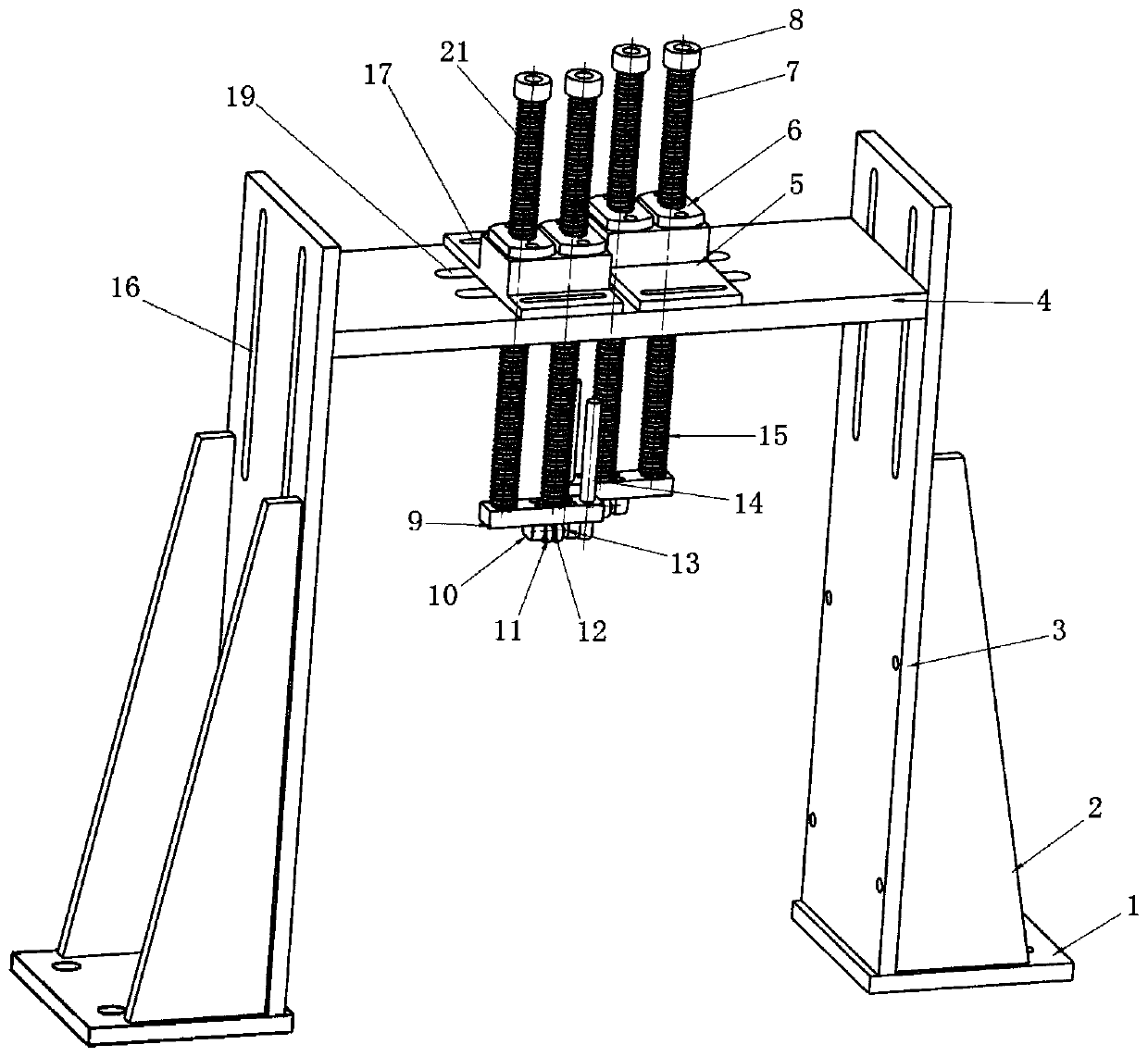

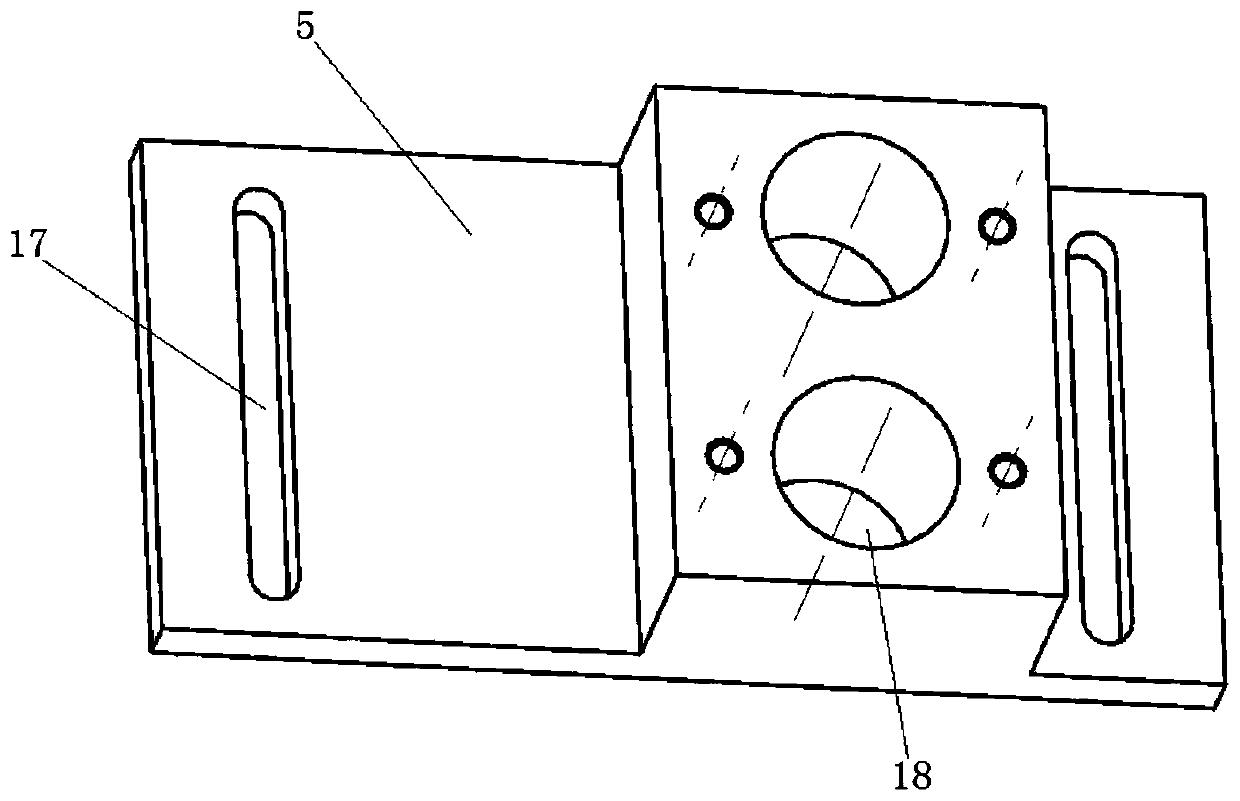

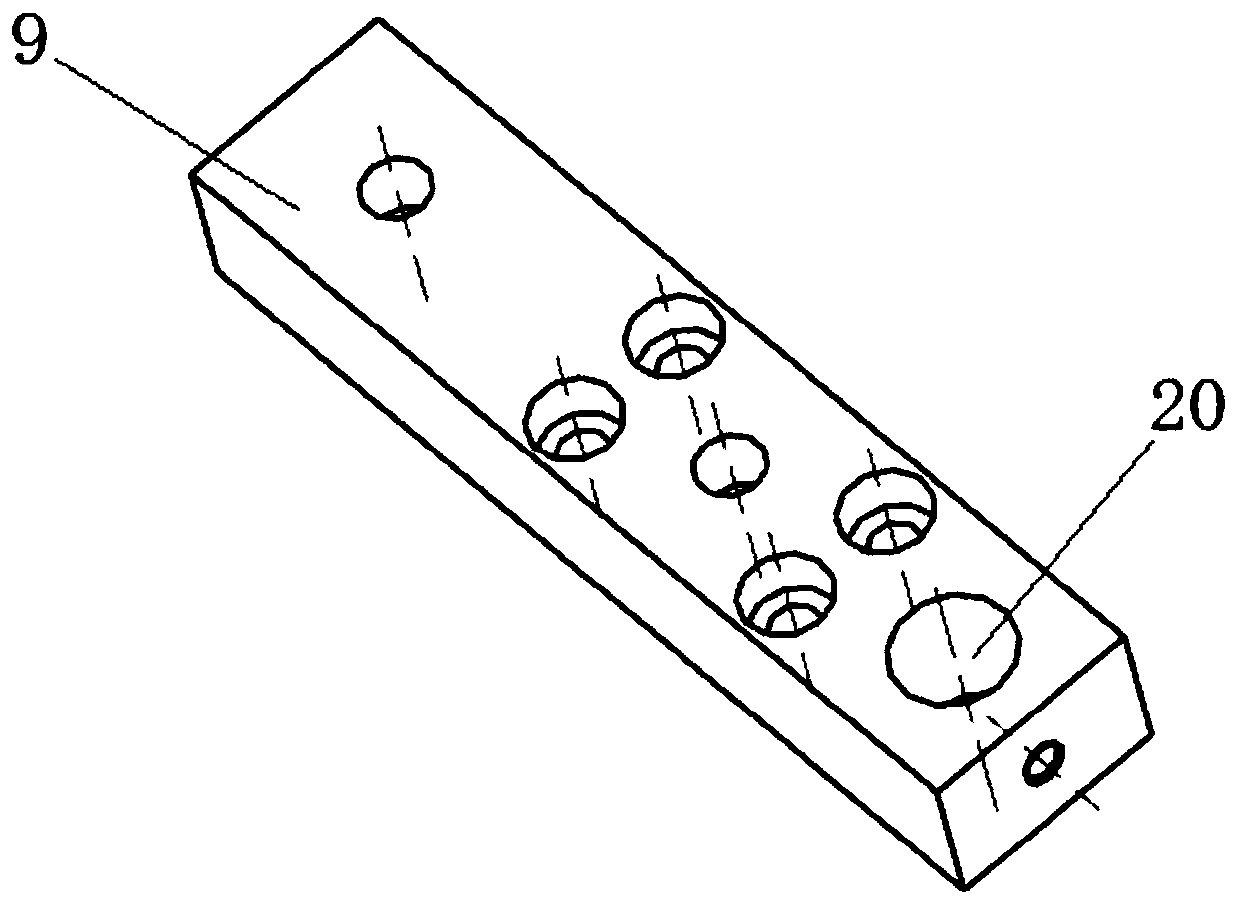

[0030] Such as Figure 1-4 As shown, the vertical plate 3 is fixed on the base 1 by bolts, and the two sides are supported by the support plate 2. The base 1 is fixed on the end workbench of the water-inflated square pipe production line by bolts; the two sides of the beam plate 4 are locked by bolts and gaskets. Tightly in the waist groove 16 of the vertical plate, the height can be controlled by moving up and down in the waist groove 16 of the vertical plate. Similarly, the waist groove 17 of the moving fixture at both ends of the moving fixture 5 is locked in the screw hole of the second beam plate through the bolt gasket. For horizontal positioning, the linear bearing 6 is clearance-fitted with the through hole 18 of the moving fixture 5, and locked and positioned through the threaded holes on both sides; the limit shaft end 8 is fixed on the top of the long axis 7 for limit, and the long axis 7 Pass the upper spring 21 (short spring), the linear bearing 6 and the beam pla...

Embodiment 2

[0034] Such as figure 1 A stainless steel square welded pipe weld seam eddy current on-line detection device shown includes a base 1, a vertical height adjustment mechanism arranged on the base 1, a horizontal displacement adjustment mechanism arranged on the vertical height adjustment mechanism, and a vertical displacement adjustment mechanism arranged on the vertical height adjustment mechanism. The elastic up and down movement mechanism arranged on the horizontal displacement adjustment mechanism and the rolling mechanism and the eddy current point probe mechanism respectively arranged at the bottom of the elastic up and down movement mechanism are moved.

[0035] Among them, the base 1 is provided with a pair, and the vertical height adjustment mechanism includes a pair of vertical plates 3 respectively arranged on the two bases 1 and a beam plate 4 horizontally arranged between the two vertical plates 3. The upper edge of the vertical plate 3 is vertically A vertical plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com