Automatic detection equipment for optical module

An optical module and automatic detection technology, applied in the direction of optical instrument testing, testing optical performance, measuring devices, etc., can solve the problems of hard contact tilt accuracy, lack of automation, human error, etc., to achieve accurate quality testing and avoid human error Pollution, volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

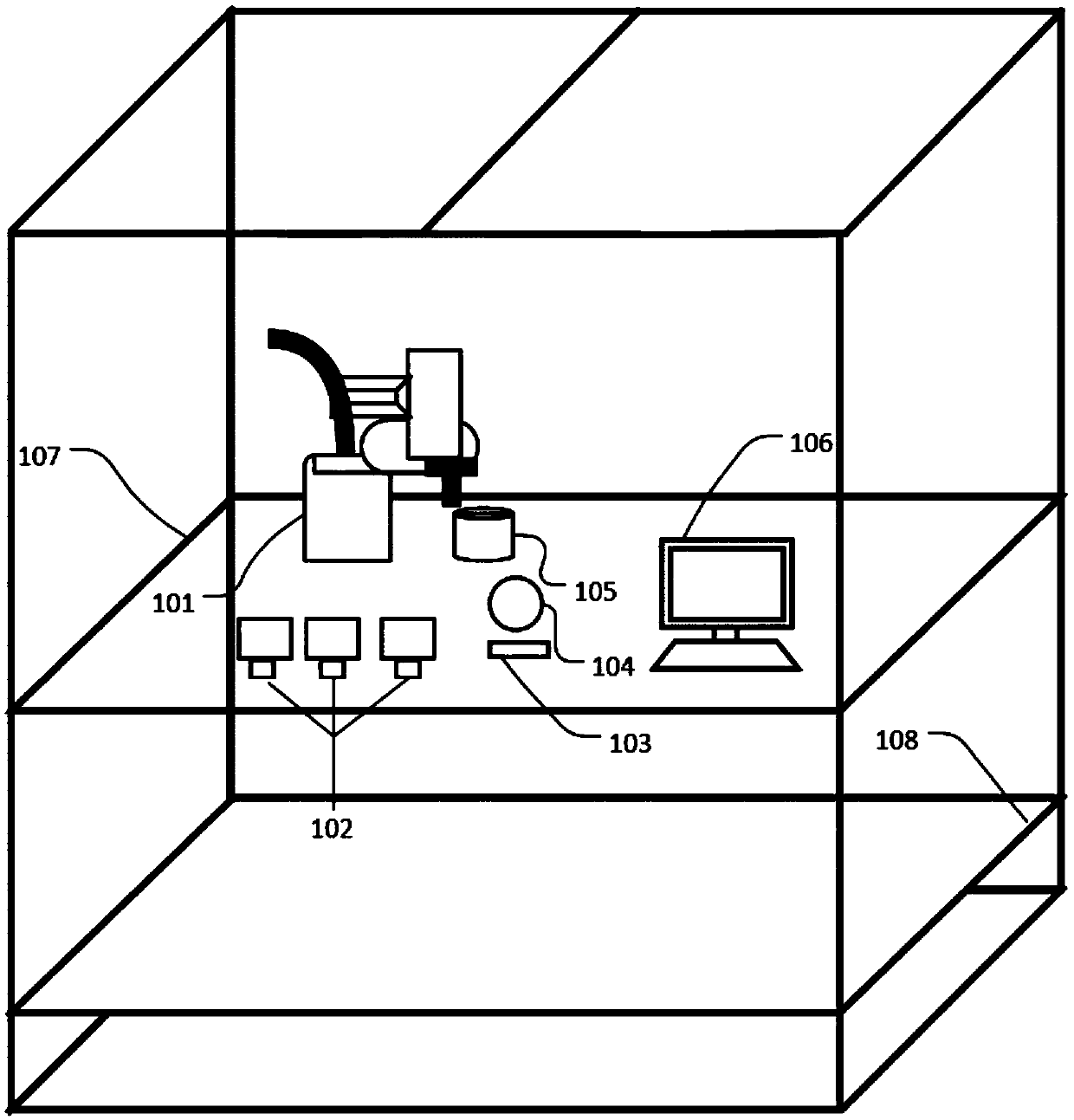

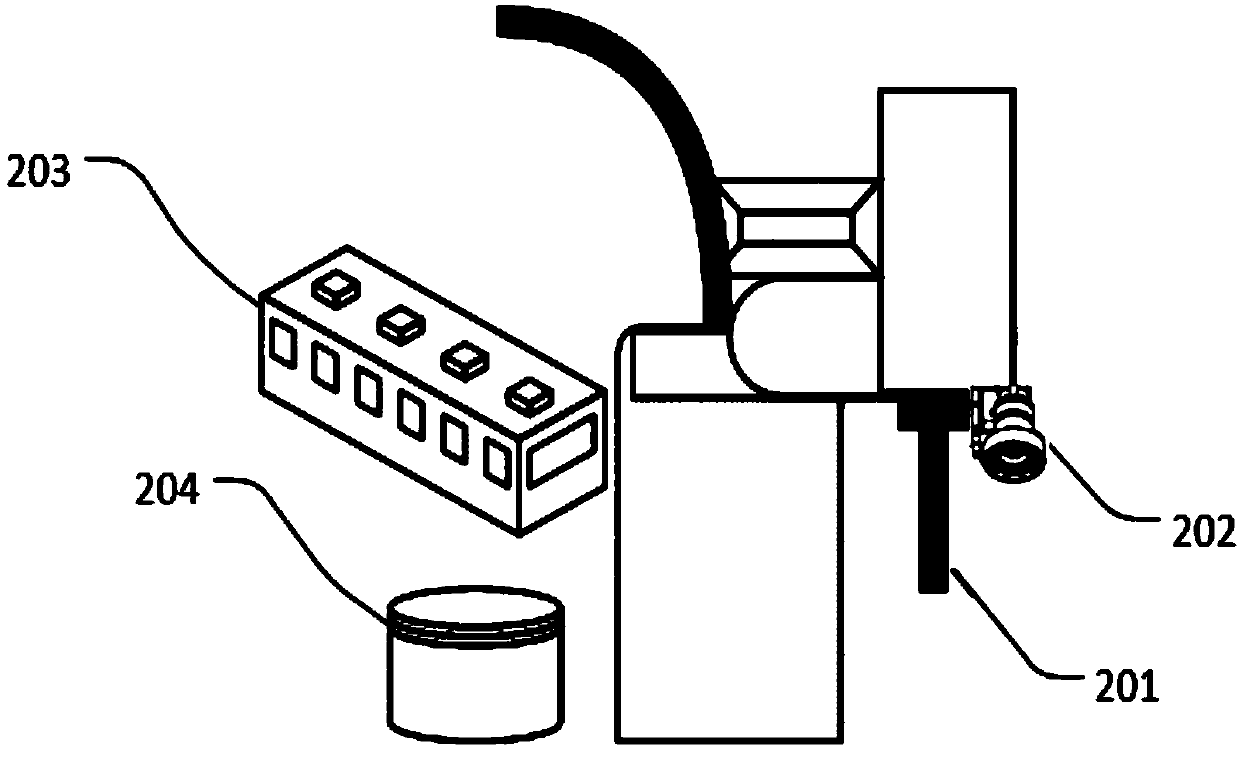

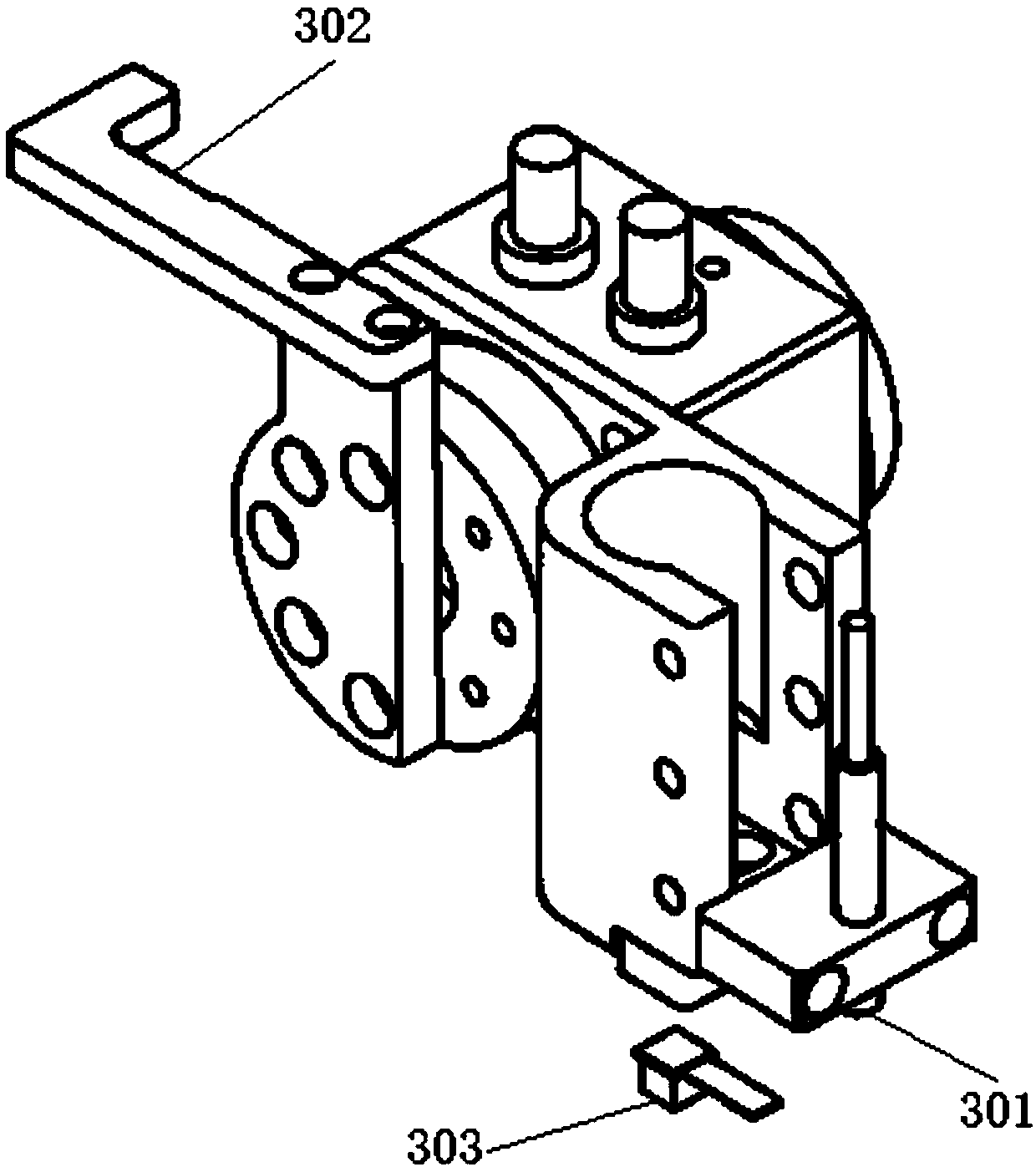

[0025] The present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings, so as to better understand the present invention, but the following embodiments do not limit the protection scope of the present invention. In addition, it should be noted that the diagrams provided in the following embodiments are only schematically illustrating the basic concept of the present invention, and only the components related to the present invention are shown in the drawings rather than the number of components, Shape and size drawing, the shape, quantity and proportion of each component may be changed according to needs during actual implementation, and the layout of the components may also be more complex.

[0026] It should be noted that although the projection module detected in the embodiment of the present invention refers to the infrared structured light projection module, the detection device in the embodiment can also b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com