Quick-disassembly winding device

A rewinding device and quick-release technology, which can be used in strip winding, transportation and packaging, thin material handling, etc., and can solve problems such as low blanking work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

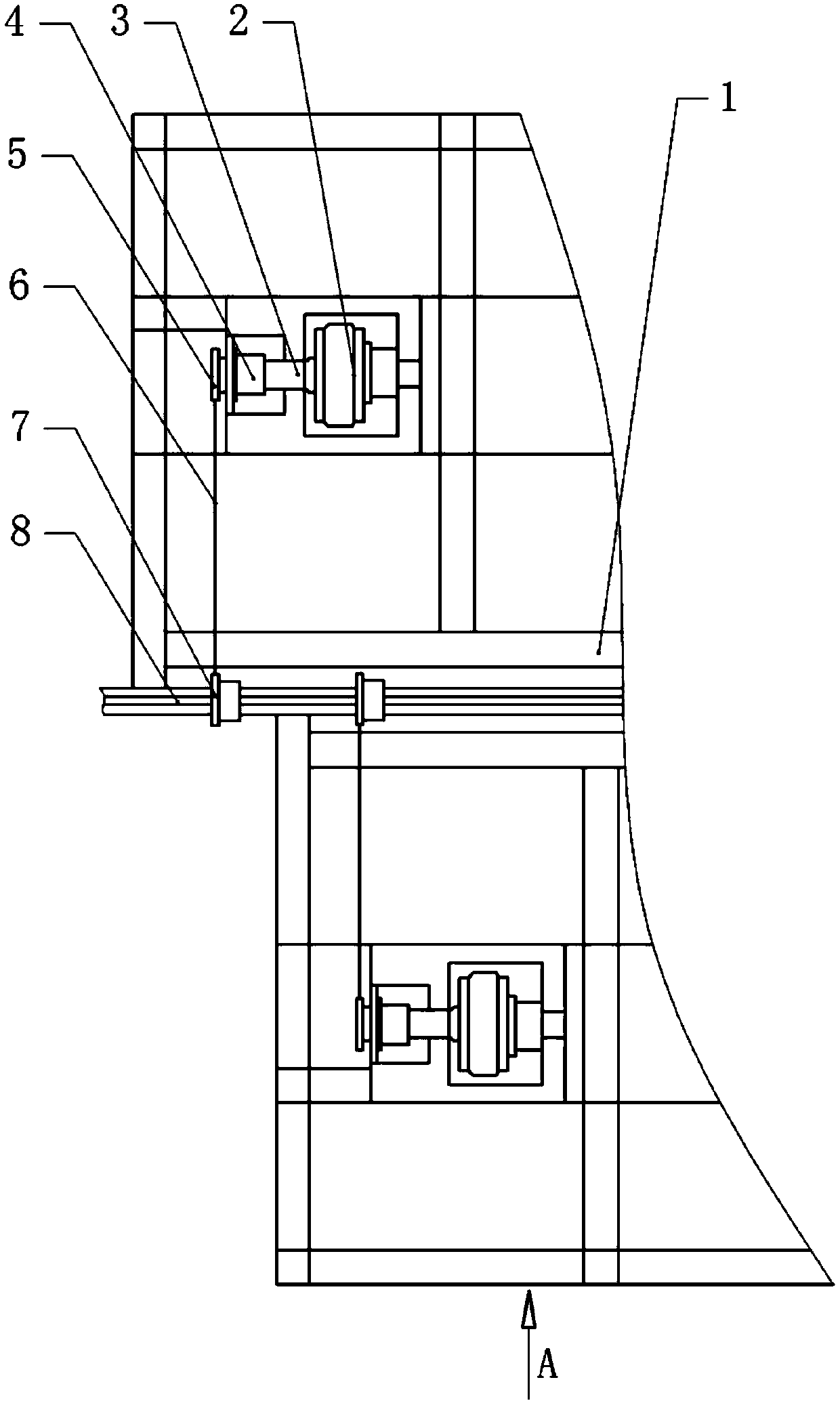

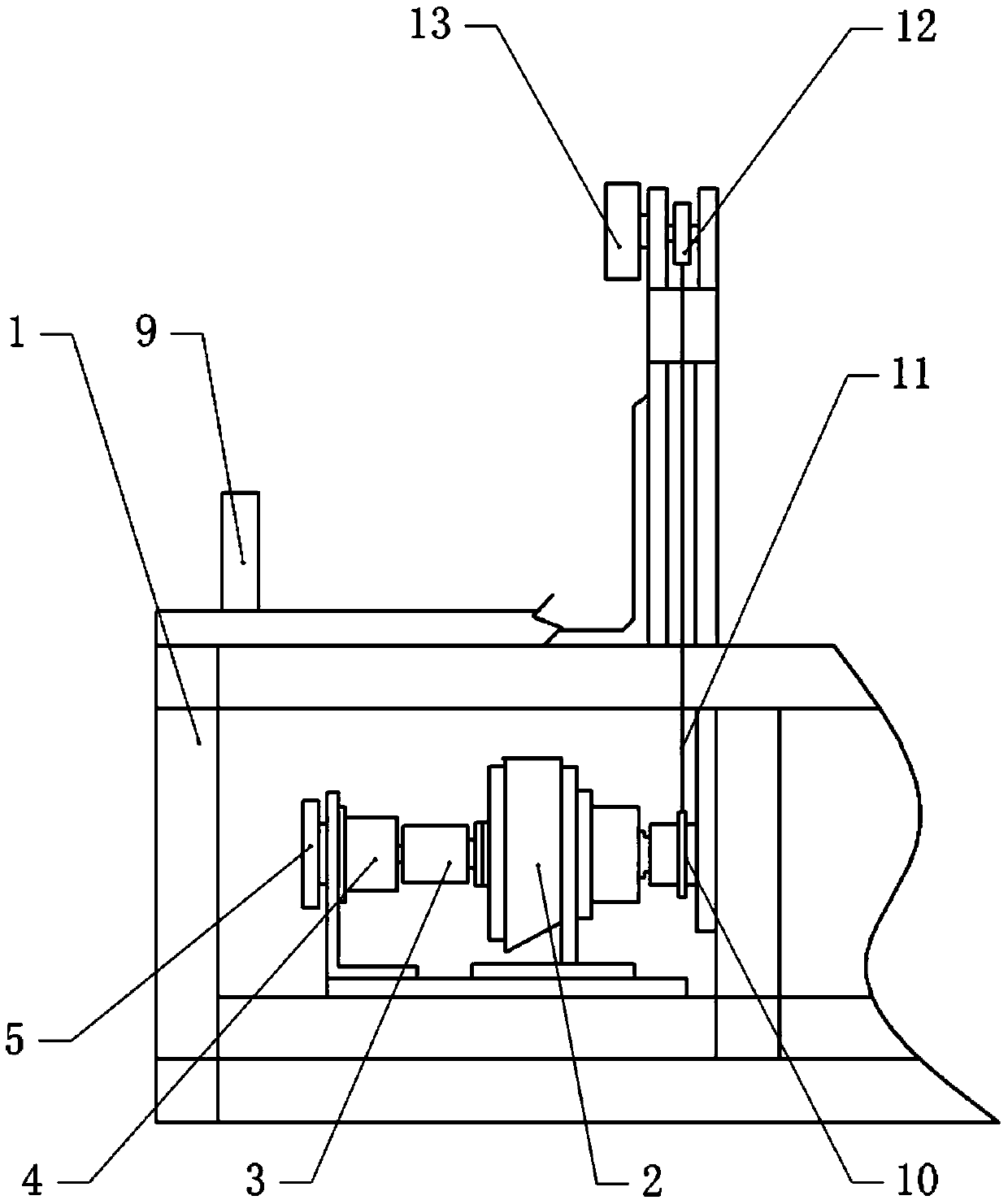

[0029] A quick-release winding device, basically as attached figure 1 And Figure 4 As shown, the frame 1 and the intermittent transmission mechanism installed on the frame 1 are included.

[0030] As attached figure 1 , 2 3, the frame 1 is provided with a drive shaft 8 along the transverse direction of the frame 1, and two bearings and a bearing seat for mounting the bearings are provided along the axial direction of the drive shaft 8. The bearing seat is fixed on the frame 1.

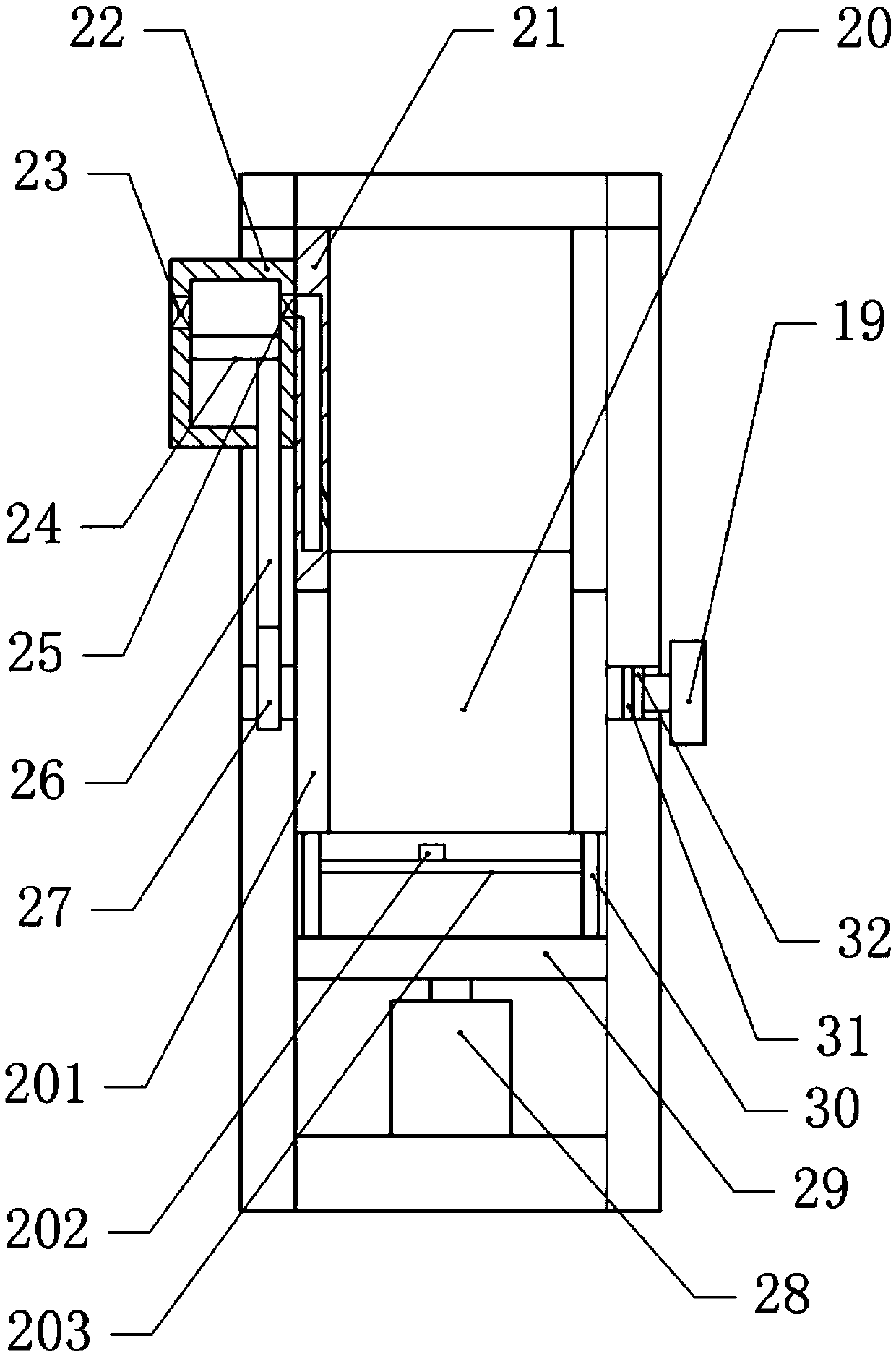

[0031] As attached figure 1 , The frame 1 on both sides of the driving shaft 8 is respectively provided with a winding mechanism, and the winding mechanisms on both sides are arranged back and forth along the axial direction of the driving shaft 8. Attached figure 2 And image 3 , The winding mechanism includes a winding roller 20 and a winding frame fixed on the frame 1. The winding roller 20 is arranged along the axial direction of the driving shaft 8, and both ends of the winding roller 20 are rotatably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com