Grid leveling device

A technology for leveling devices and grids, applied in shearing devices, accessories of shearing machines, maintenance and safety accessories, etc., can solve problems such as operator injury and uneven grid edges, improve work efficiency, avoid cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

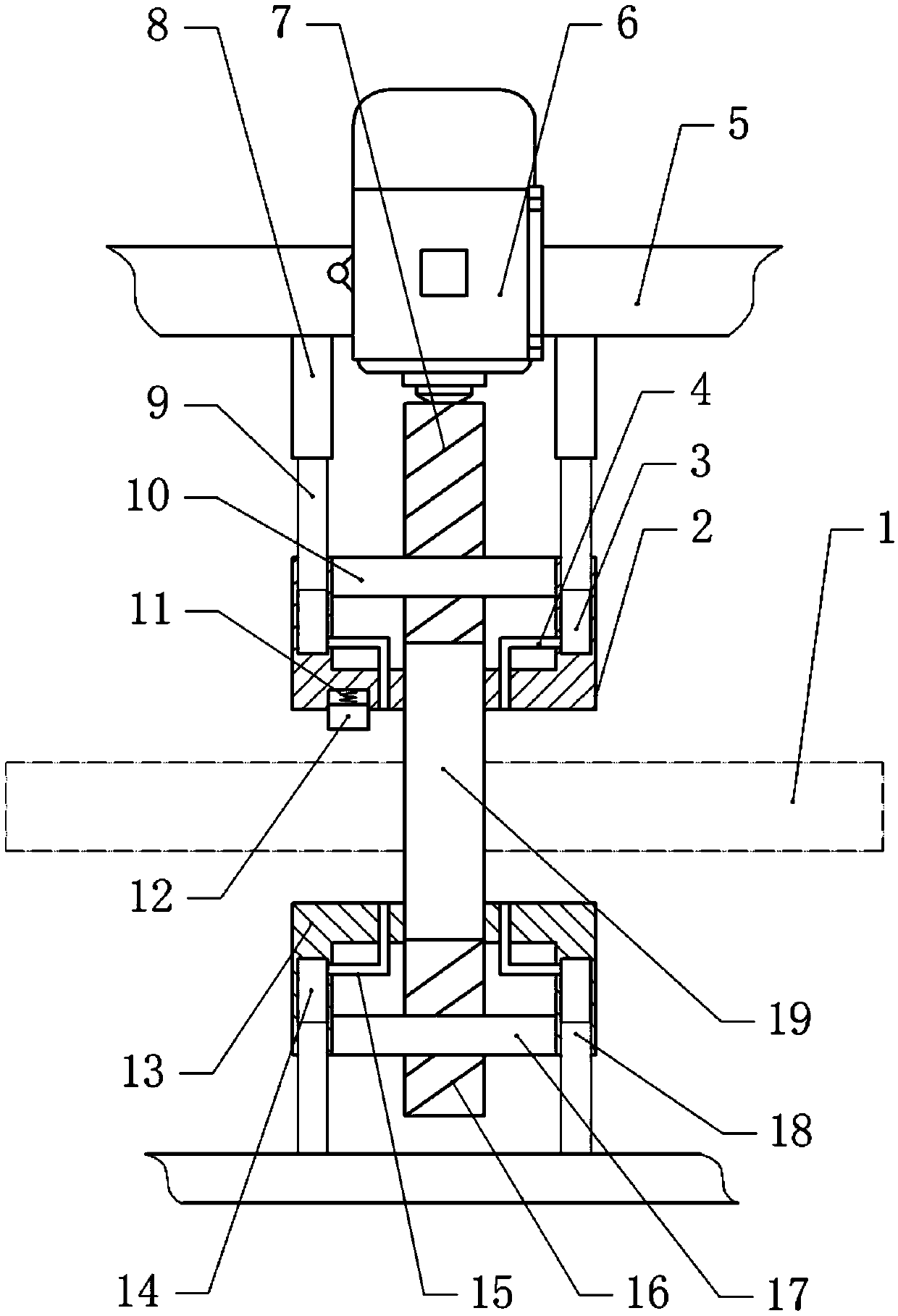

[0020] A grid leveling device, basically as attached figure 1 , including a frame body 5 and a driving mechanism fixed on the top of the frame body 5, the driving mechanism is a servo motor 6 or a stepping motor, and the servo motor 6 is selected in this embodiment.

[0021] The output shaft of the servo motor 6 faces downward, and the first screw rod 7 is fixed on the output shaft, the cutting knife 19 is fixed on the bottom of the first screw rod 7, and the transmission device is perpendicular to the paper surface to convey the grid 1 outwards, and the blade of the cutting knife 19 is vertical Inwardly of the paper surface, two fixed rods 8 fixed on the frame body 5 are arranged on both sides along the radial direction of the first screw rod 7 , and slide rods 9 are fixed on the lower parts of the fixed rods 8 . The bottom of the slide bar 9 is provided with a U-shaped frame 2, and the two side walls of the U-shaped frame 2 are provided with an air cavity 3, and a connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com