Additive composition, application of composition, koumiss product, and methods for determining centrifugal sedimentation rate and sensory score of koumiss product

A technology of centrifugal precipitation and dairy products, which is applied in the direction of milk preparations, applications, dairy products, etc., and can solve problems such as protein precipitation, whey precipitation, and poor stability of kosher milk products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] In the following examples and comparative examples,

[0054] Determination method of centrifugal sedimentation rate:

[0055] In a graduated centrifuge tube, weigh 10 g of yogurt sample, centrifuge at 3500 r / min for 20 min, let it stand for 10 min, pour off the supernatant to measure the residual mass.

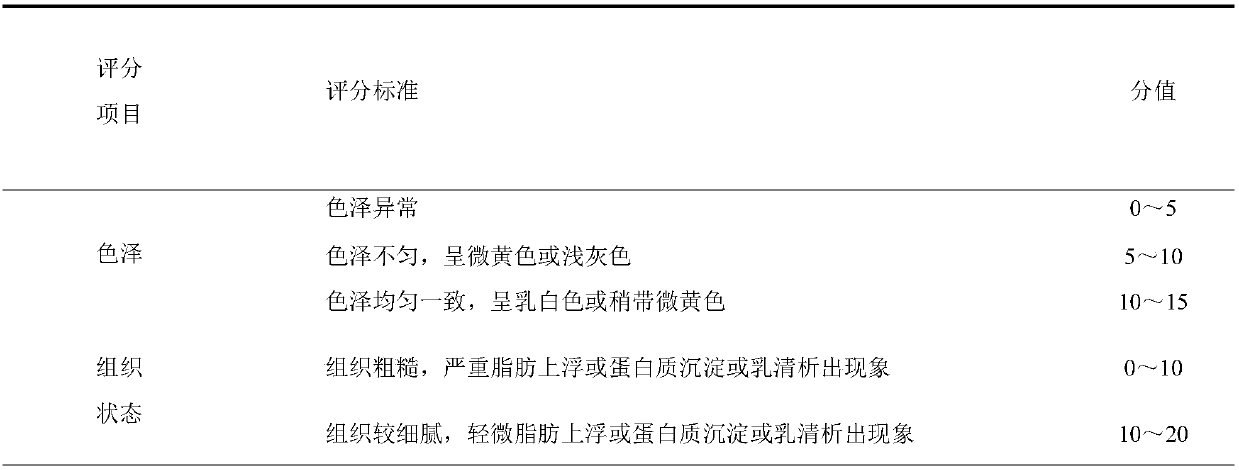

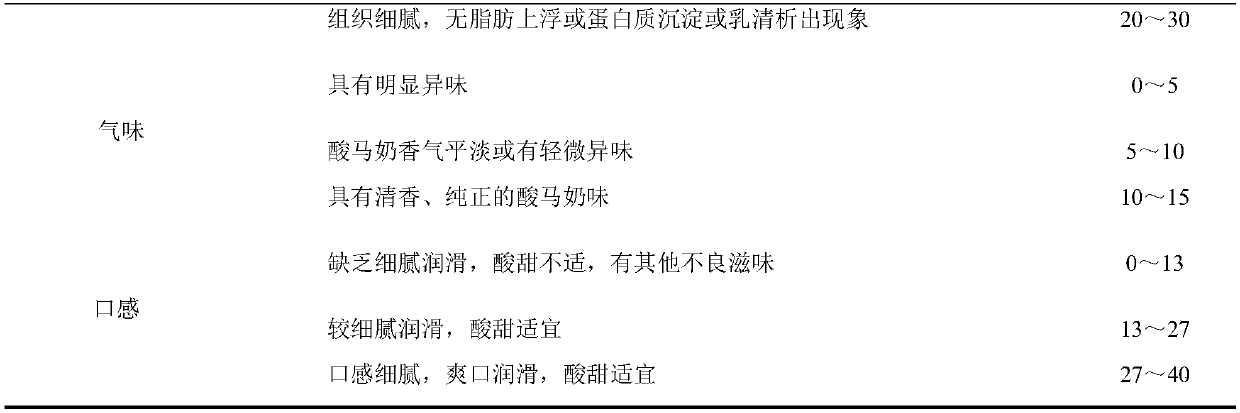

[0056] Sensory evaluation:

[0057] A sensory evaluation team composed of 10 people evaluated the fermented milk samples from four aspects: color, texture, smell, and taste. A 100-point scoring system is used, and the higher the score, the better the product. Evaluation method: put the sample in a transparent cup, first observe the color and tissue state under sufficient light, then smell the smell, then rinse your mouth and taste the taste.

[0058] Sensory Evaluation Standards

[0059]

[0060] High-ester pectin was purchased from CPK (China) Company, item number: 115H.

[0061] Propylene glycol alginate was purchased from Qingdao Mingyue Seaweed Co., Ltd., it...

preparation example 1

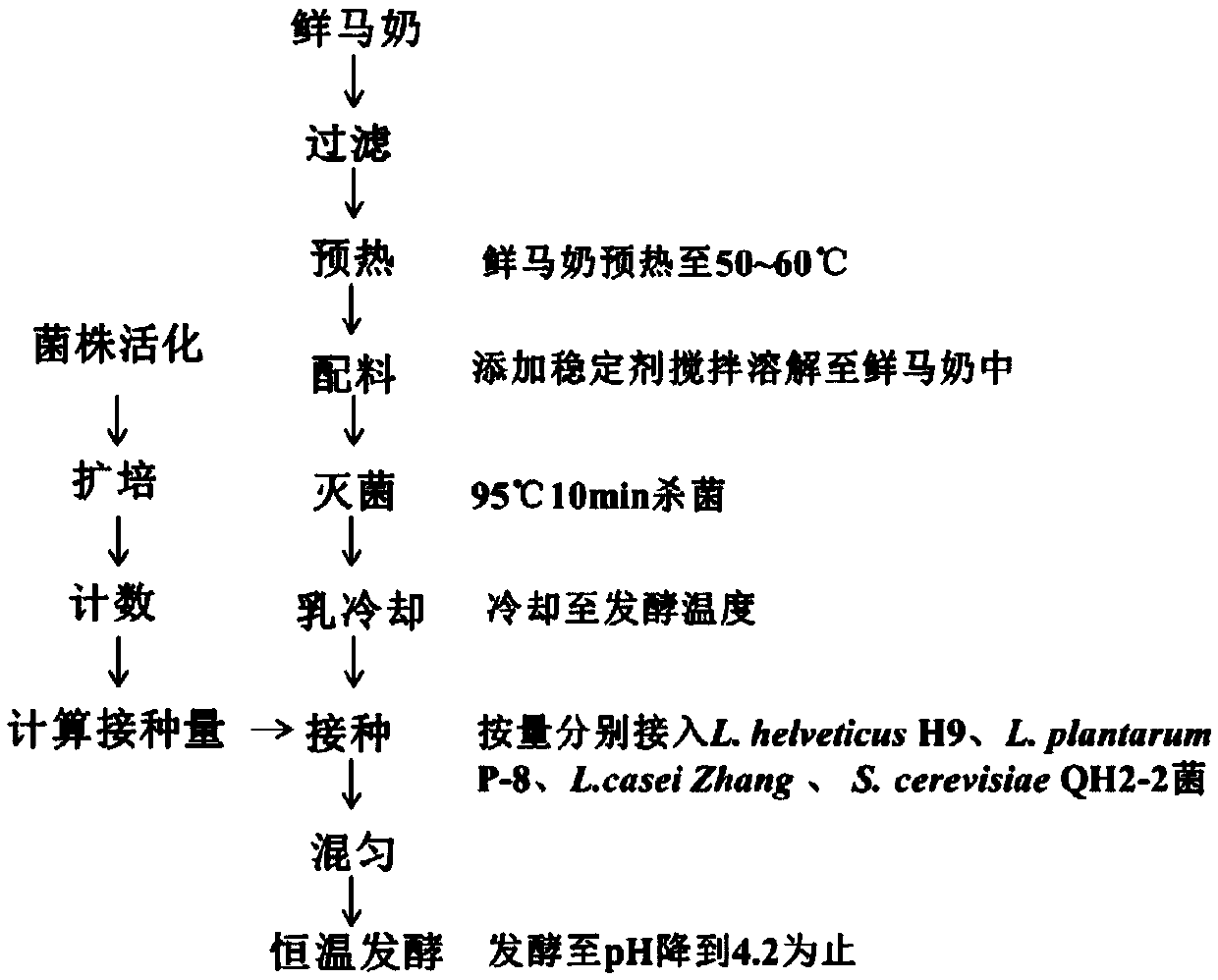

[0064] according to figure 1 The kumiss was prepared in the same way, wherein, the fermentation temperature was about 40° C., and the inoculum amount of the fermentation strain was 3%.

preparation example 2

[0066] The fermented milk was prepared according to the method of Preparation Example 1, except that mare's milk was replaced with cow's milk to obtain milk fermented milk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com