High-speed fabric breaking device based on lubricating oil drainage fabric pressing vibration reduction

A cloth pressing device, high-speed technology, used in the cutting of textile materials, textiles and papermaking, etc., can solve the problem of lubricating oil dripping onto the cloth, cutter holder or cloth pressing device, different thickness of cloth, scrap of cloth, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

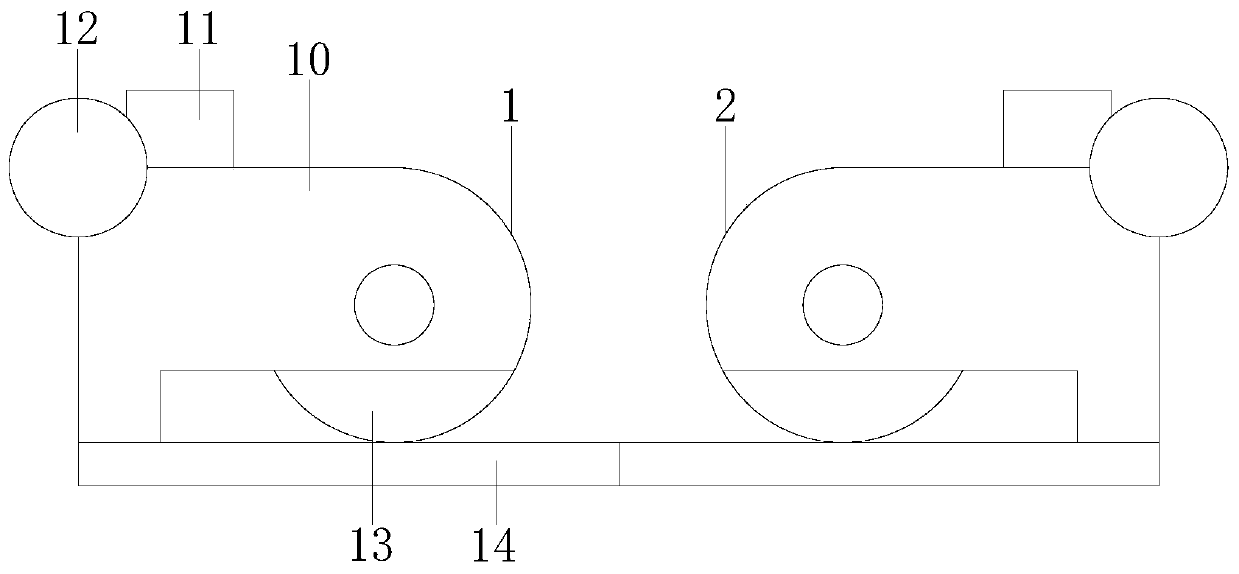

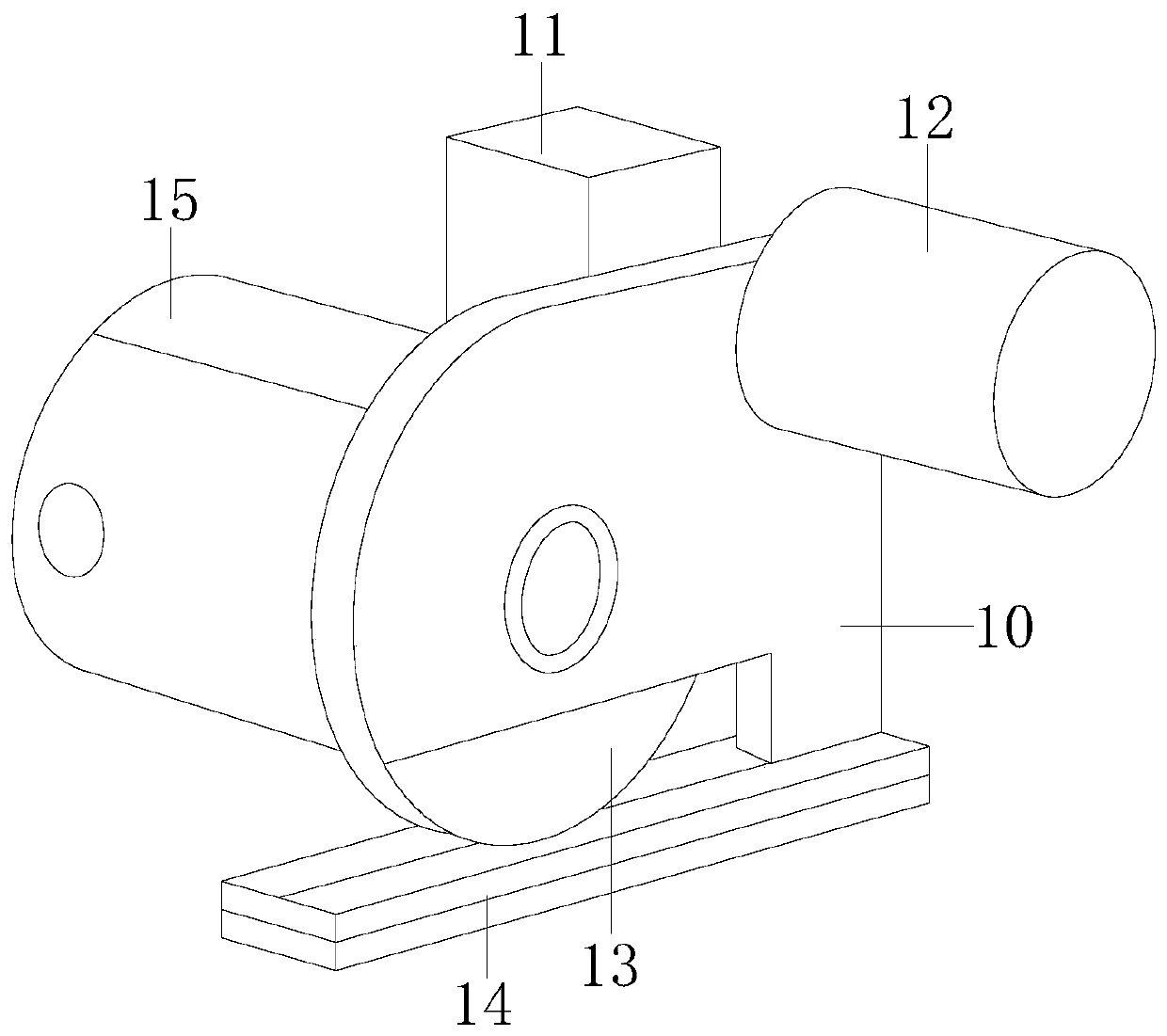

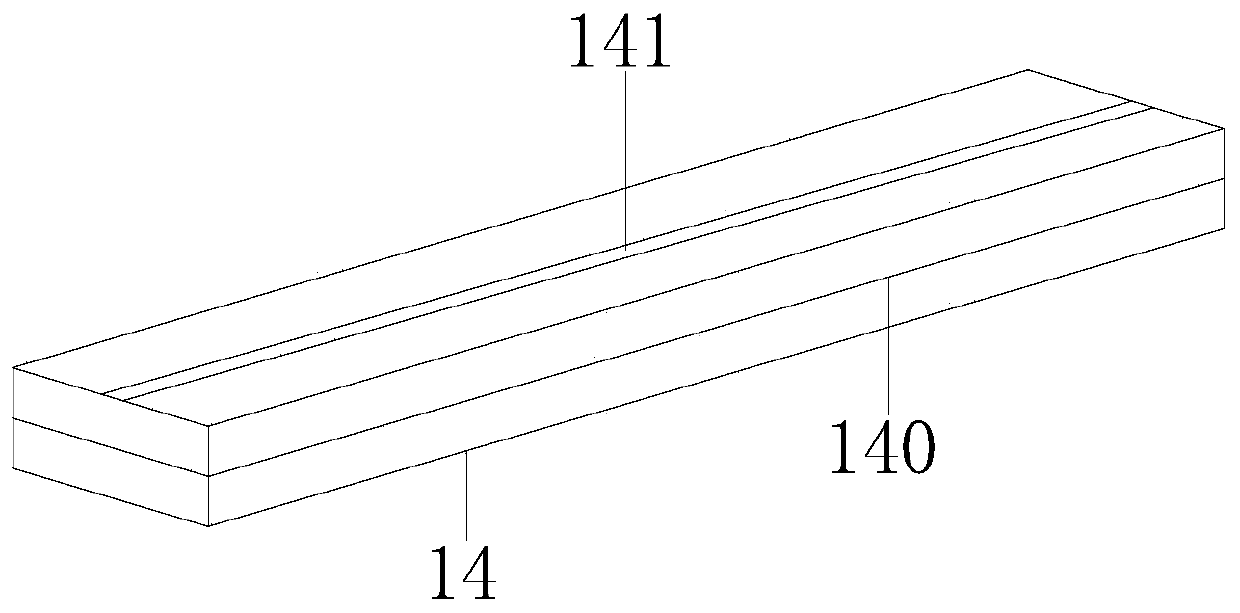

[0030] Example 1 see Figure 1-6, the present invention provides a technical solution for a high-speed cloth cutting device based on lubricating oil drainage and pressing cloth for vibration reduction: its structure includes a left structure 1 and a right structure 2, and the left structure 1 and the right structure 2 have the same structure, so The left structure 1 is assembled and connected with the right structure 2, and the left structure 1 is composed of a knife rest 10, a cloth pressing device 11, a balance pile 12, a cutting knife 13, a cutting knife seat frame 14, and a high-speed motor 15. The cutting knife 13 is installed on the knife rest 10, and the cloth pressing device 11 presses the cloth according to the up and down movement of the cutting knife 13 and releases the cloth, and the auxiliary cutting knife 13 cuts the cloth accurately. On the knife rest frame 14, the knife rest 10 is installed and connected with the cloth pressing device 11, the balance pile 12 is...

Embodiment 2

[0032] Example 2 see Figure 7-10 , the present invention provides a technical solution for a high-speed cloth breaking device based on lubricating oil drainage and cloth pressure reduction: the structure of the covering device 1103 includes an oblique mounting plate 300, an oblique spring plate 301, a solid rod 302, a bolt rod 303, a cladding The slat 304, the inner circle cladding plate 305, the inclined mounting plate 300, the inclined spring plate 301 are installed and connected with the solid rod 302, the bolt rod 303 is screwed with the solid rod 302 and the cladding strip 304, and the cladding strip 304 is installed and connected with the inner circle cover plate 305. The cover plate device 1103 moves up and down through the bolt rod 303, so that every time the cloth press frame 110 moves up and down one step, the cover plate device 1103 is fixed one step, and the vibration when moving up and down and friction will not cause the pressure plate to loosen, and the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com