Chemical phosphorus-removal accurate dosing system and chemical phosphorus-removal accurate dosing control method

A chemical phosphorus removal and control method technology, applied in chemical instruments and methods, multiple fluid ratio control, ratio control, etc., to achieve the effect of solving the hysteresis of reaching the standard and increasing the stability of the effluent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

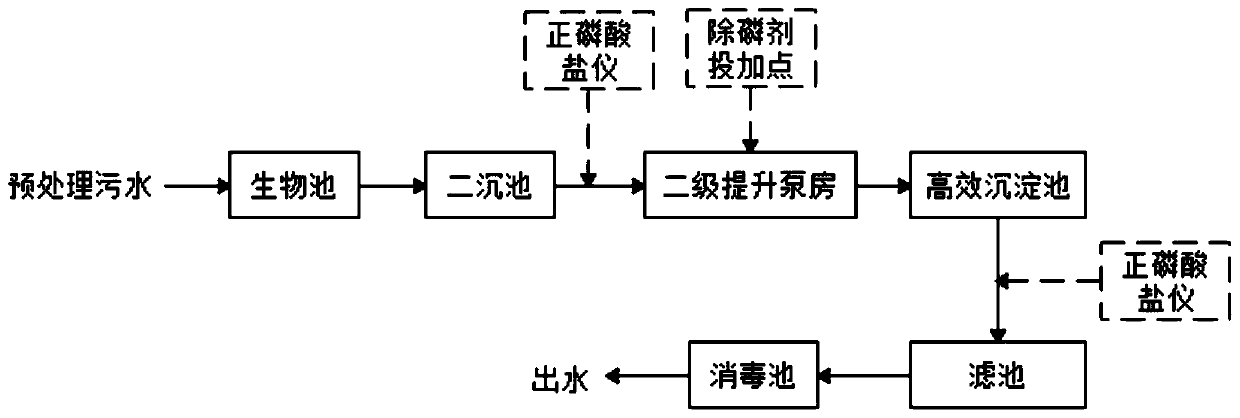

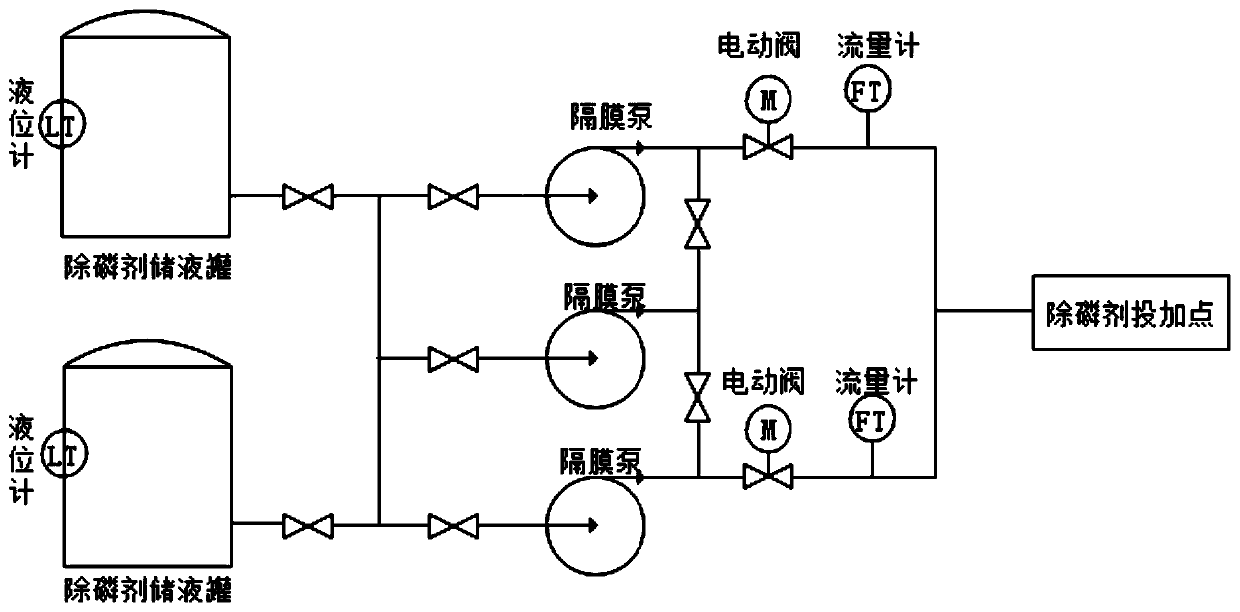

[0045] A precise dosing system for chemical phosphorus removal of the present invention includes a treatment pool group, a control component and a phosphorus removal agent dosing component. Such as figure 1 As shown, the treatment pool group includes a biological pool, a secondary sedimentation tank, a secondary lifting pump room, a high-efficiency sedimentation tank, a filter tank and a disinfection tank. In this treatment tank group, the number of primary sedimentation tanks, biological tanks, secondary sedimentation tanks, high-efficiency sedimentation tanks, filters and contact disinfection tanks can be set to one or more according to specific needs. Biological pools include anaerobic pools, anoxic pools and aerobic pools which are arranged in sequence. Orthophosphate online monitors are installed at the outlet of the secondary sedimentation tank and the outlet of the high-efficiency sedimentation tank, and flow meters are installed at the inlet of the sewage plant.

[0...

Embodiment 2

[0069] The basic content of this example is the same as that of Example 1, the difference is that in this example, the phosphorus removal agent is polyferric sulfate, the active ingredient content is 12%, and the density is 1.45g / mL. At a certain moment, when the influent total phosphorus concentration is 4.30mg / L, the concentration of orthophosphate in the secondary sedimentation tank is C 1 When it is 1.45mg / L, the β value is 10.4. According to the concentration of orthophosphate in the effluent of the secondary sedimentation tank and the corresponding dosing coefficient, calculate the dosing rate:

[0070] m 1 =15.05(C 1 -C sp / α)β

[0071] Among them: M 1 ——dosing rate, the mass of PFS solution per liter of sewage, mg / L;

[0072] C 1 ——Concentration of orthophosphate in the effluent of the secondary sedimentation tank, mg / L;

[0073] C sp ——The target value of orthophosphate concentration in the effluent of the high-efficiency sedimentation tank is 0.3mg / L;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Relative molecular mass | aaaaa | aaaaa |

| Relative molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com