Bio-degradable film hot-press forming bag making machine

A technology of biodegradable film and thermoforming, which is applied in bag making, flexible container manufacturing, paper/cardboard containers, etc. It can solve the problems of poor bag making effect and complex structure, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

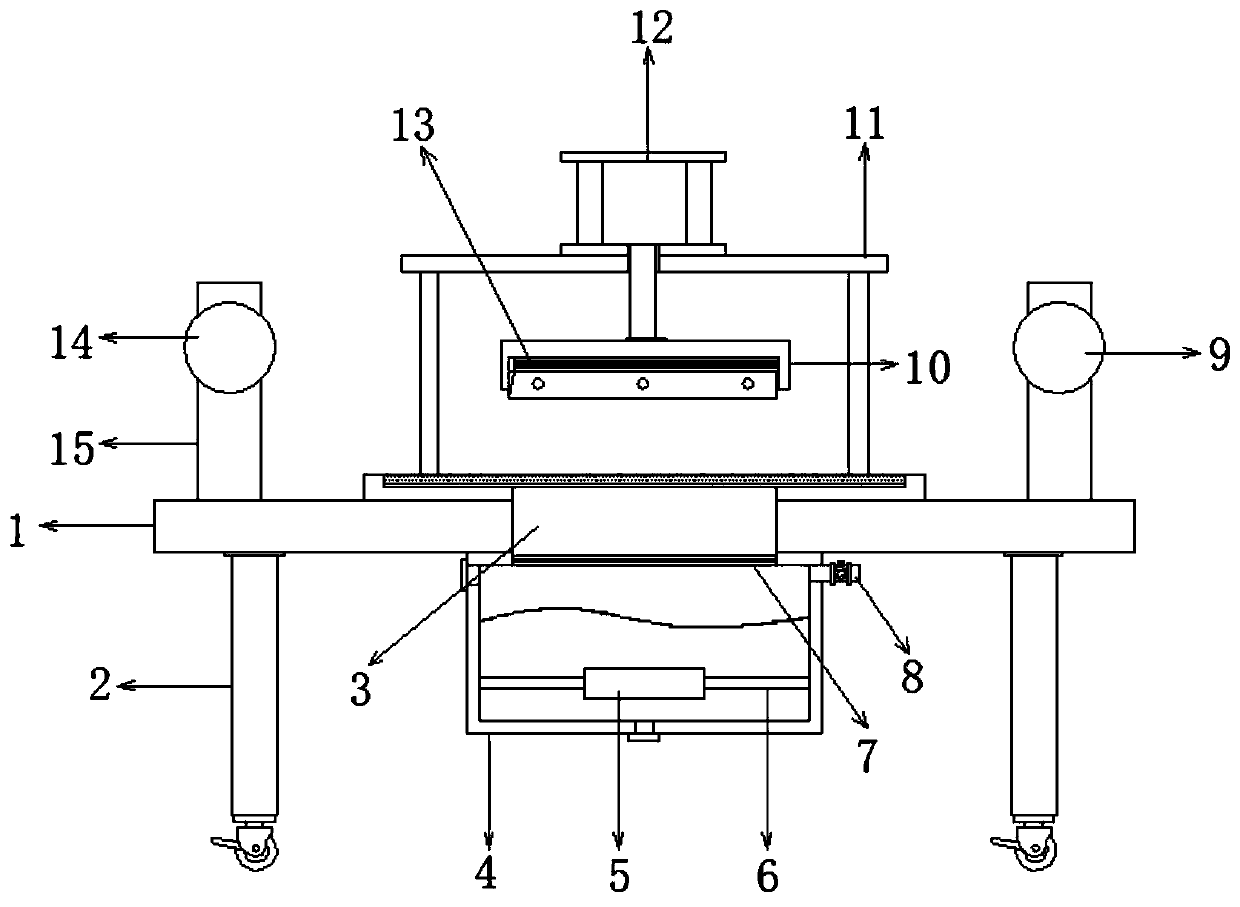

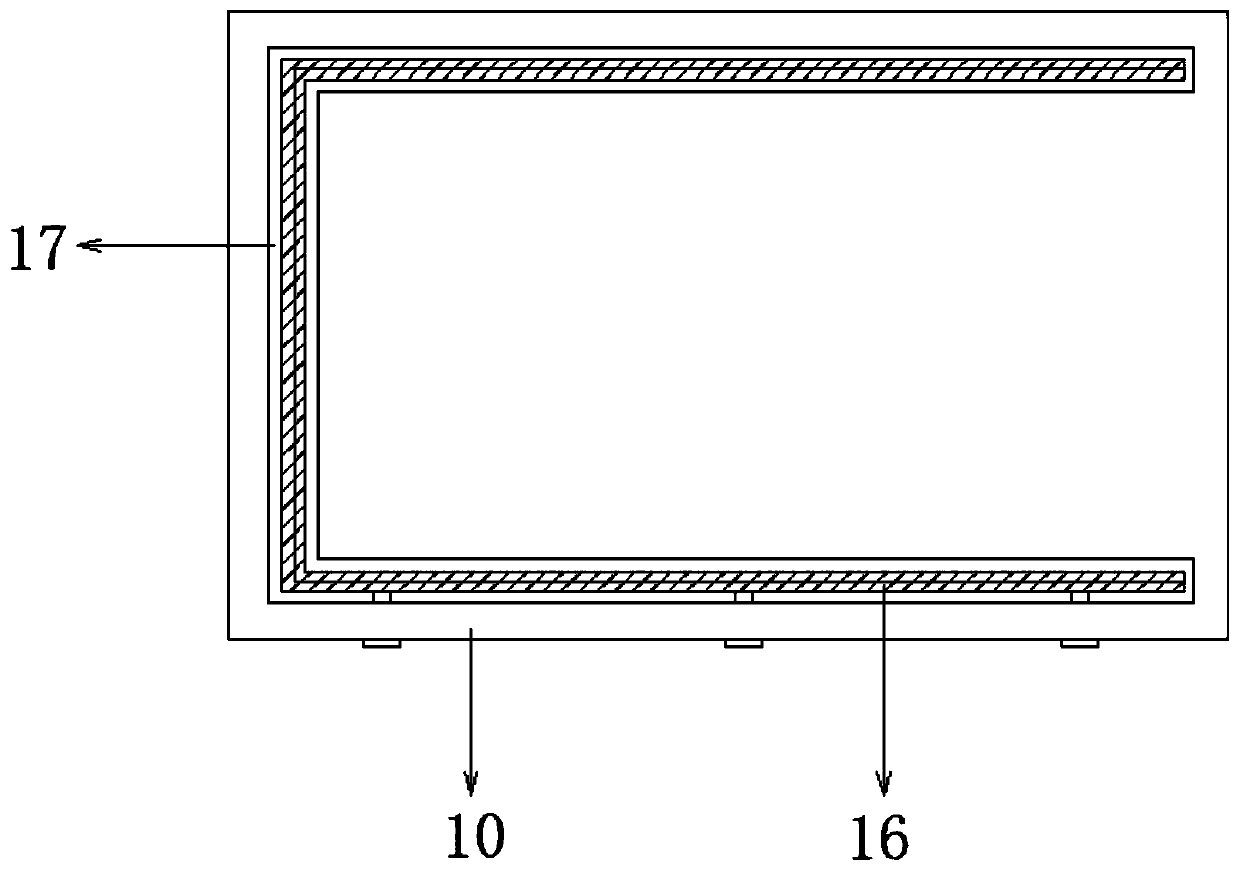

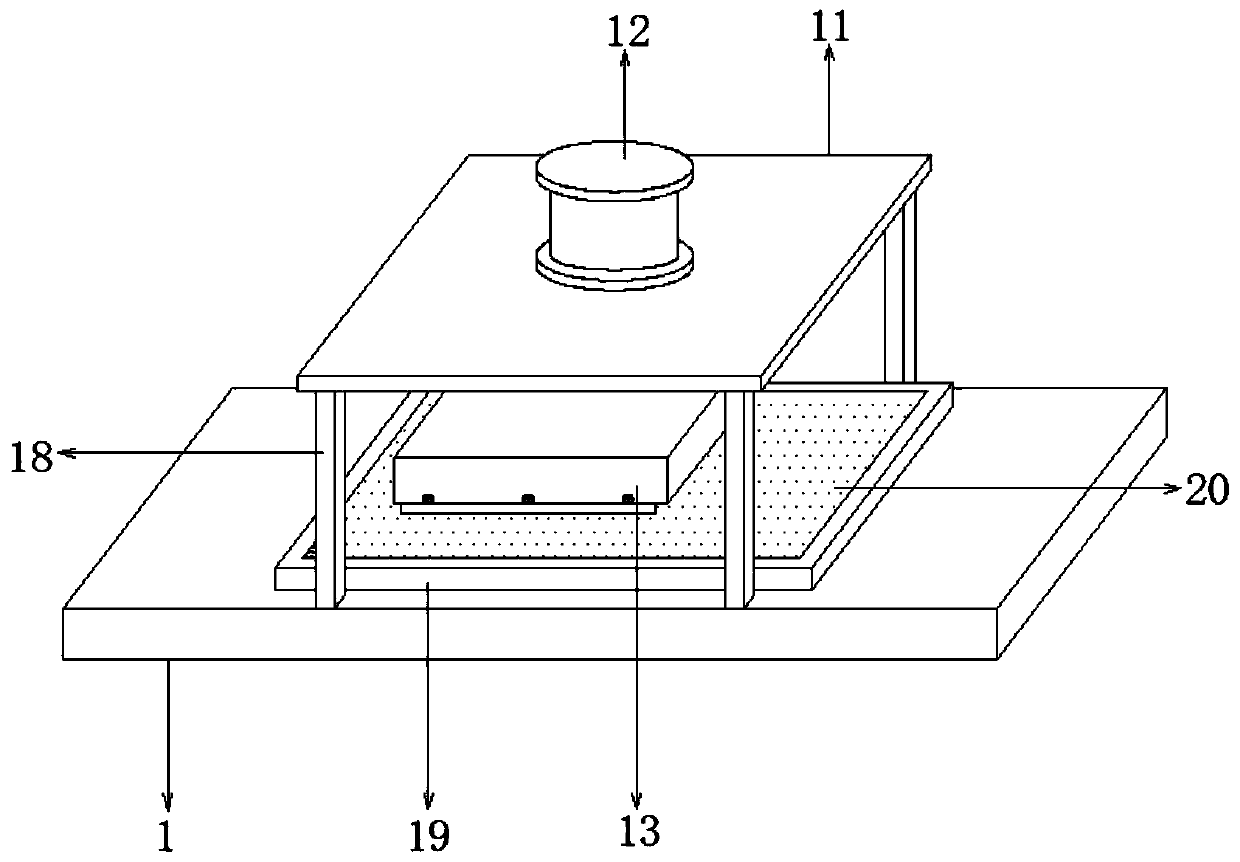

[0027] A biodegradable film thermocompression forming bag making machine, such as Figure 1-3 As shown, the support base plate 1 is included, and one end of the outer wall of the top side of the support base plate 1 is welded with a first support column 15, and the top of one side of the first support column 15 is rotatably connected with an unwinding roller 14, and the top middle position of the support base plate 1 The support platform 19 is connected by bolts, and the four corners of the top of the support base plate 1 near the support platform 19 are welded with fixed columns 18. The top of the fixed columns 18 is welded with a top plate 11, and the middle position of the top plate 11 is connected with a hydraulic cylinder 12 by bolts. And the bottom of the piston end of the hydraulic cylinder 12 is connected with the mounting seat 10 by bolts, and the outer walls on both sides of the bottom of the mounting seat 10 and the outer wall at one end are provided with a common mo...

Embodiment 2

[0035] A biodegradable film thermocompression forming bag making machine, such as Figure 4 As shown, this embodiment makes the following improvements on the basis of Embodiment 1: the two ends of the outer walls on both sides of the top of the support base plate 1 are welded with fixed blocks, and the tops of the opposite sides of the fixed blocks are rotatably connected with guide rollers 21 .

[0036] In this embodiment, when in use, the degradable film is laid on the support platform 19 after passing through the bottom of the guide roller 21, so as to maintain the stability of the degradable film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com