Anti-permeable tipping paper

A technology for tipping paper and base paper, applied in paper, papermaking, specialty paper, etc., can solve the problems of filter deformation, reduced air permeability, liquid extravasation, etc., and achieves the effect of increasing comfort and balancing the ability of smoke to pass through.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

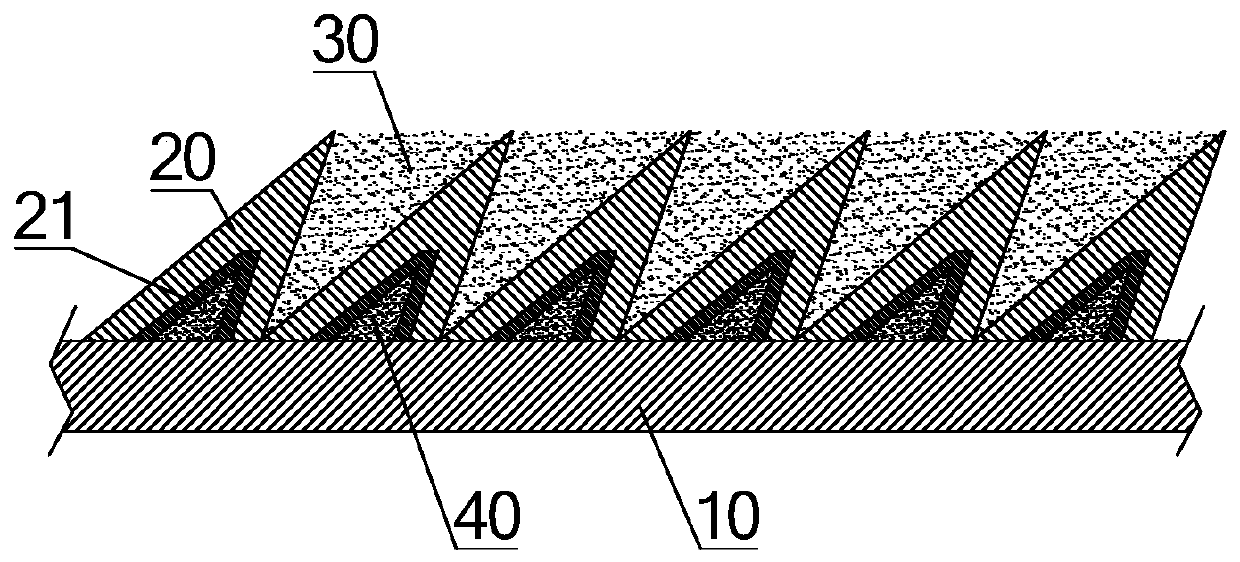

[0022] Examples, see figure 1 with figure 2 Shown: anti-penetration tipping paper, including base layer 10 prepared from tipping base paper. That is, after the base layer 10 is wrapped with cellulose acetate and rolled, it can form a common filter tip. In this embodiment, explosive beads are arranged in the acetate fiber. Explosive beads are relatively common at present, and capsules containing liquids such as essential oils are usually set inside. After being pressed, the capsules are broken and the liquid inside flows out, increasing the added value of cigarettes.

[0023] Further speaking:

[0024] The upper surface of the base layer 10 is adhered with a plurality of convex strips 20 extending in the left and right directions, and the section of the convex strips 20 is triangular. That is to say, use base paper such as tipping paper with appropriate hardness and cut it into long strips, then bend along a straight line of the base paper in the left and right longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com