Oil circuit structure of oil-cooled motor

An oil circuit and oil cooling technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of high cost, inability to cover cooling oil, and low reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

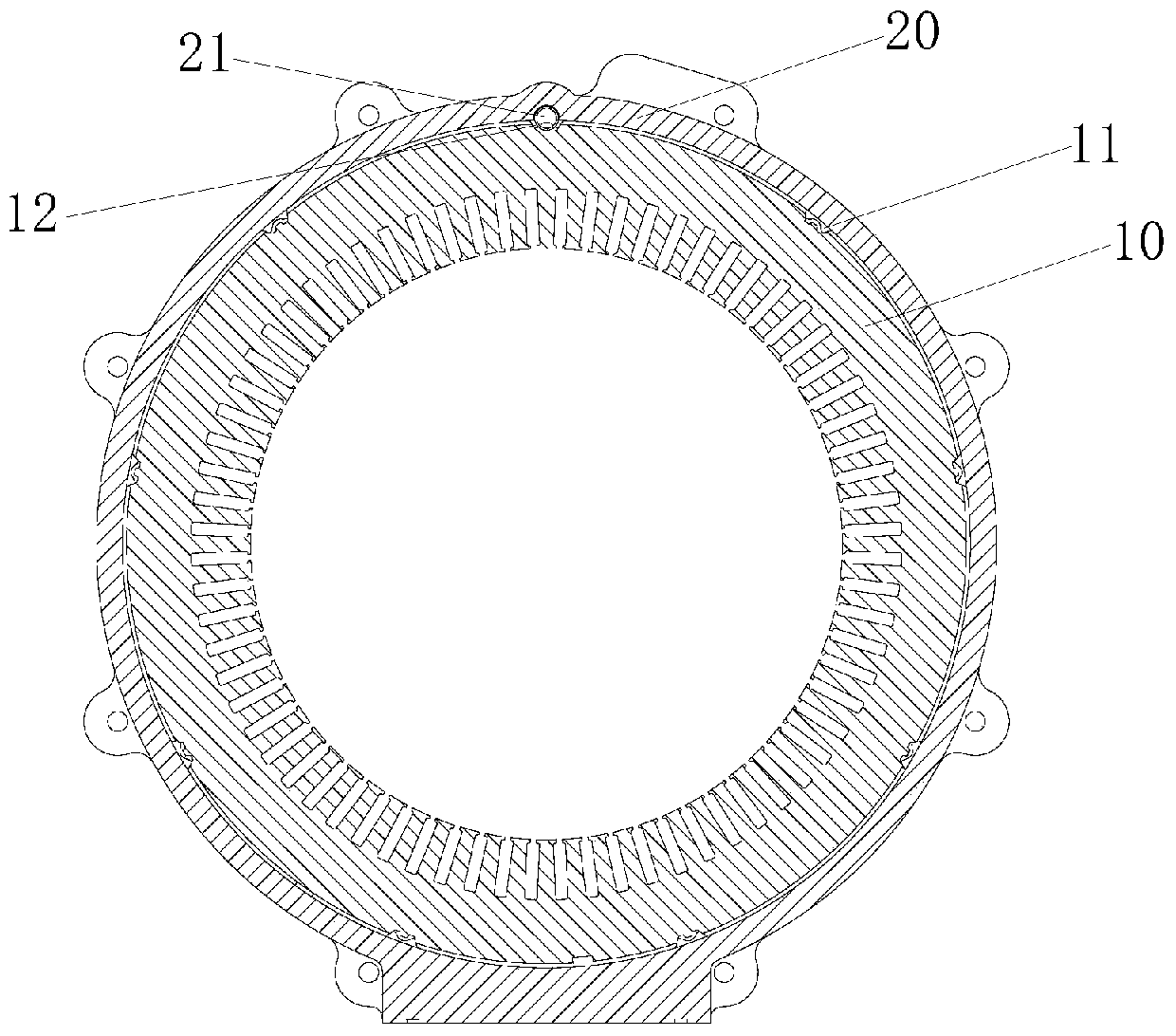

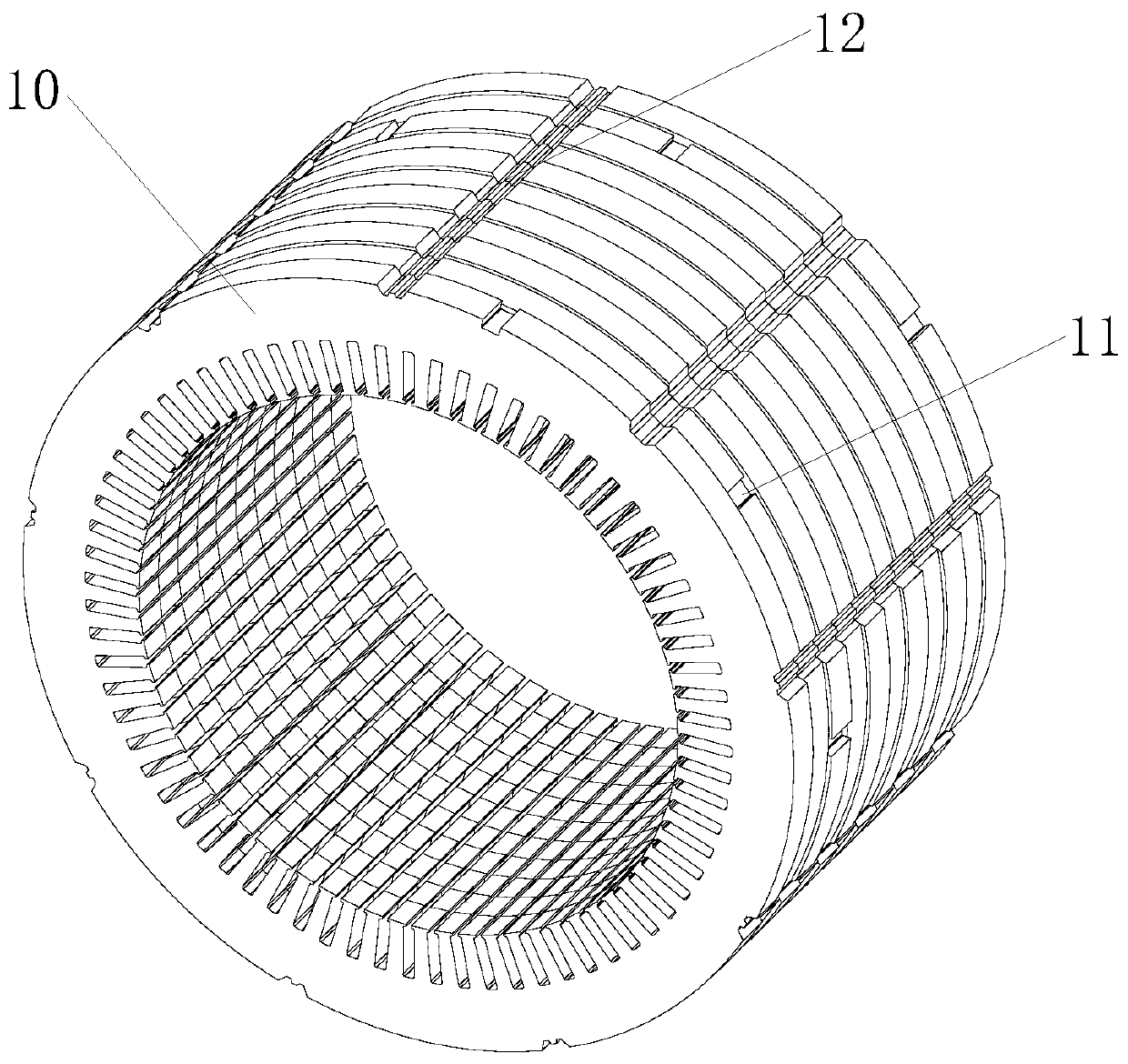

[0025] Such as figure 1 and figure 2 As shown, the oil circuit structure of the oil-cooled motor of the present invention is provided with at least one groove 11 in the circumferential direction of the outer circle of the stator core 10, and at least one groove 11 is arranged in the axial direction of the outer circle of the stator core 10. A groove 12, an oil channel 21 is provided between the inner wall of the motor casing 20 and the stator core 10, and the groove 12 in the axial direction of the outer circle of the stator core 10 guides the cooling oil through the oil channel 21 .

[0026] In this embodiment, the groove 11 has a certain depth, and the depth of the groove 11 in the circumferential direction is at least 0.5mm; the groove 12 has a certain depth, and the depth of the groove 12 in the axial direction is at least 0.5mm .

[0027] In this embodiment, the stator core 10 is composed of two or more punching pieces, the outer diameters of the punching pieces are d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com