Automatic misalignment method of unmanned equipment

An unmanned equipment and automatic technology, applied in the field of automatic distance staggering of unmanned equipment and unmanned equipment, can solve the problems of low rolling quality, lack of precision, slow speed, etc., and reduce and improve the energy consumption of operation. The effect of staggering speed and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

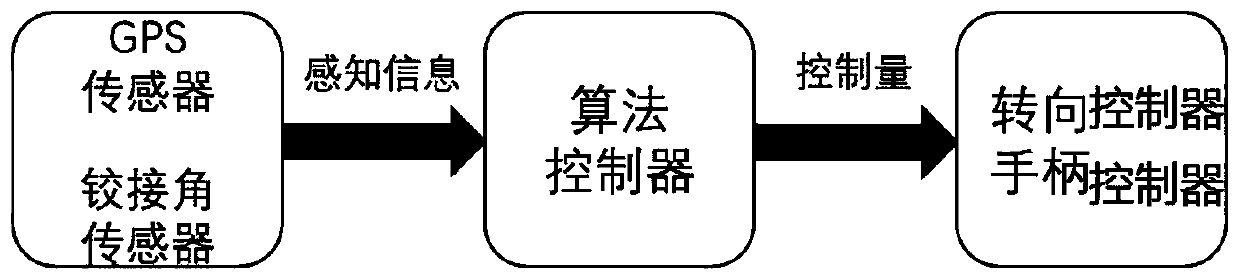

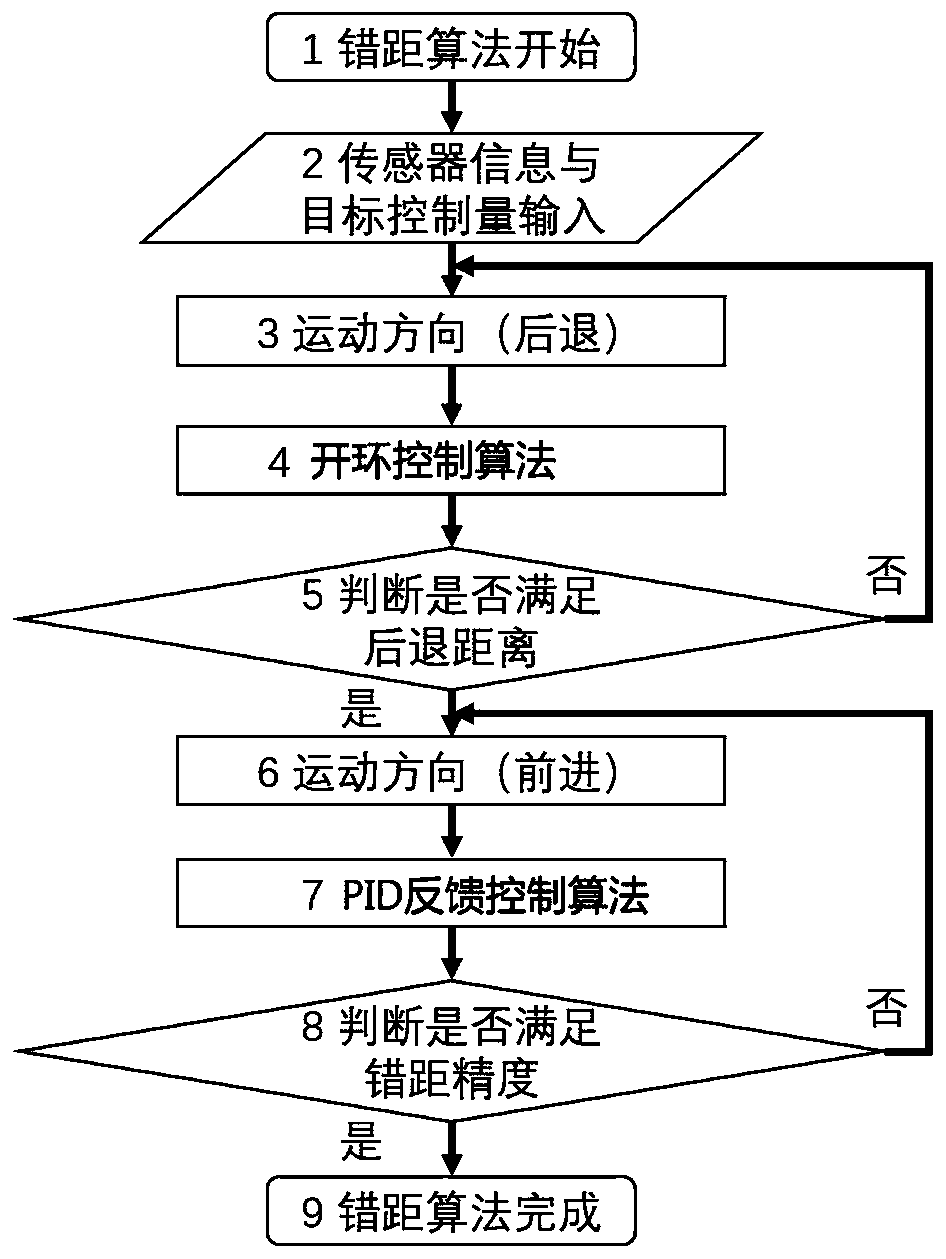

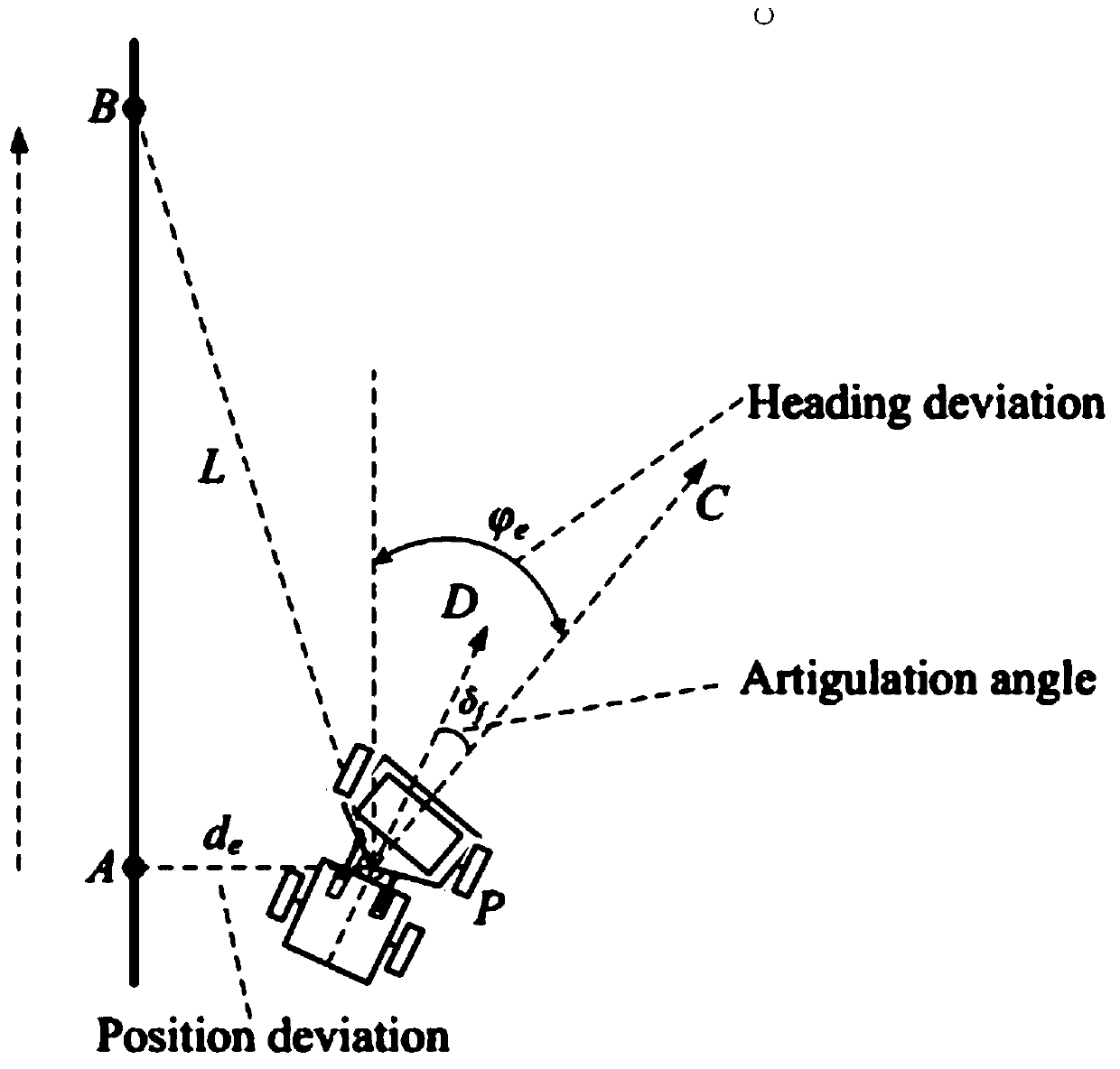

[0041] The hardware architecture scheme of the present invention is as figure 1 As shown, including sensors, algorithm controllers, and output actuators. The sensors are GPS sensors and articulation angle sensors. Use the GPS sensor to obtain the coordinate information and heading information of the unmanned equipment, use the articulation angle sensor to measure the handover angle between the front body and the rear body of the unmanned equipment, and send the two information to the algorithm controller. The output actuators are steering actuators and handle actuators. The steering actuator controls the rotation direction of the unmanned equipment by controlling the rotation of the steering wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com