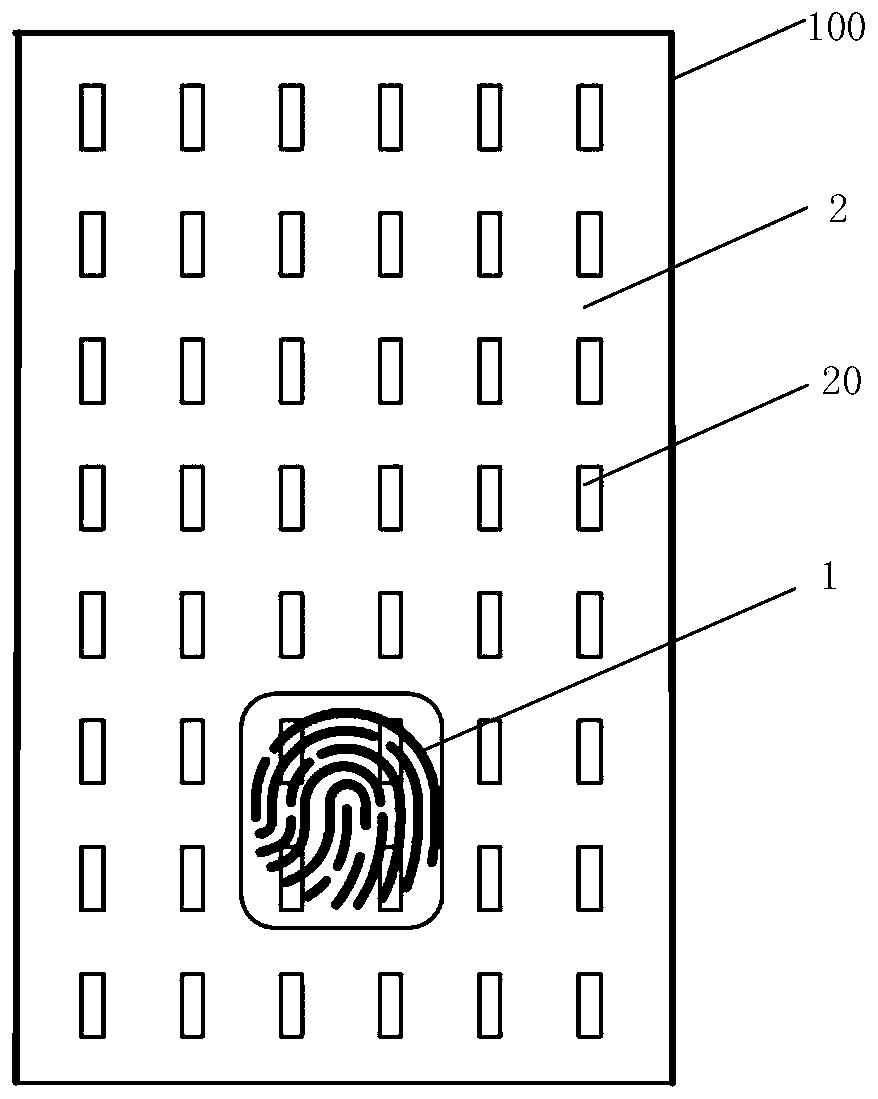

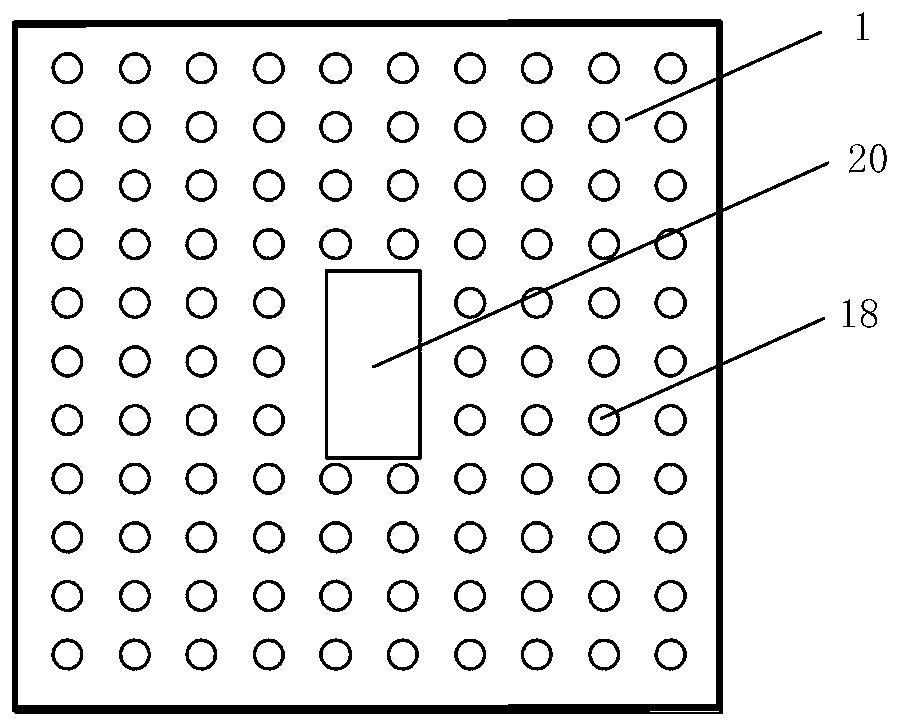

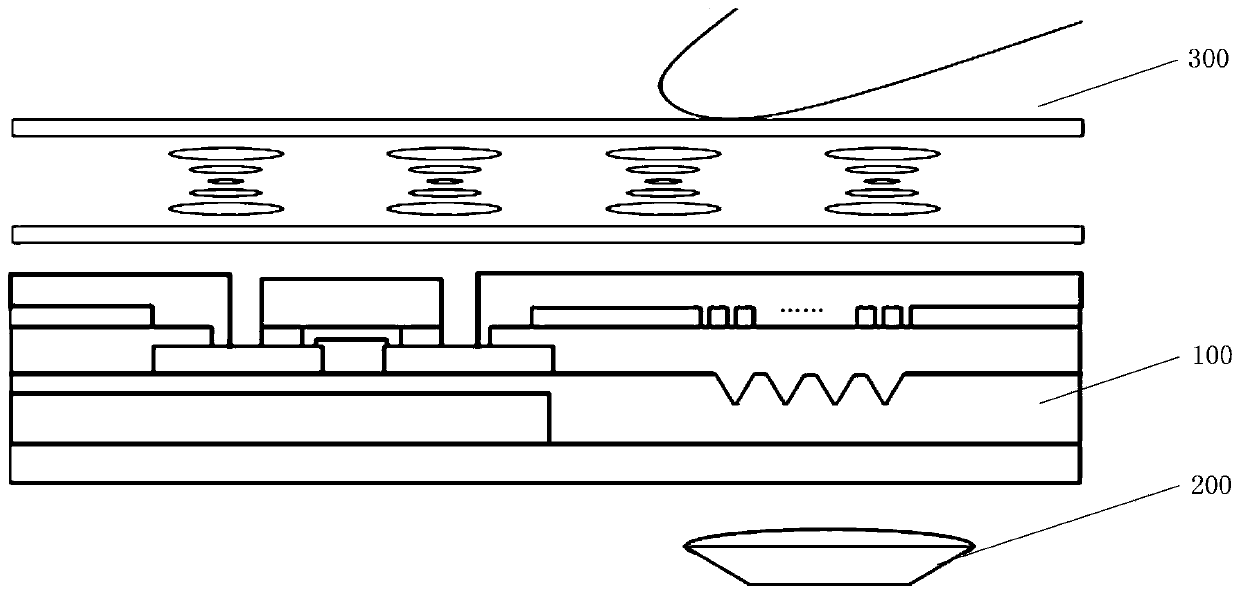

Backlight module, manufacturing method and display device

A technology of backlight module and light-concentrating structure, which is applied in optics, nonlinear optics, character and pattern recognition, etc., and can solve problems such as inability to make through holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0063]It should be noted that "on", "formed on" and "arranged on" mentioned in this article may mean that one layer is directly formed or set on another layer, or that a A layer is indirectly formed or disposed on another layer, ie there are other layers between the two layers. In this document, unless otherwise specified, the term "on the same layer" used means that two layers, parts, members, elements or parts can be formed by the same patterning process, and that the two layers, parts, members, Elements or parts are ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com