A testing device for flatness and tensile strength of sewing parts

A technology for strength detection and flatness, which is applied in the direction of measuring devices, mechanical roughness/irregularity measurement, strength characteristics, etc., can solve the problems of fabric anti-pull detection flatness, detection, etc., to achieve a large clamping range and improve Robustness and the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

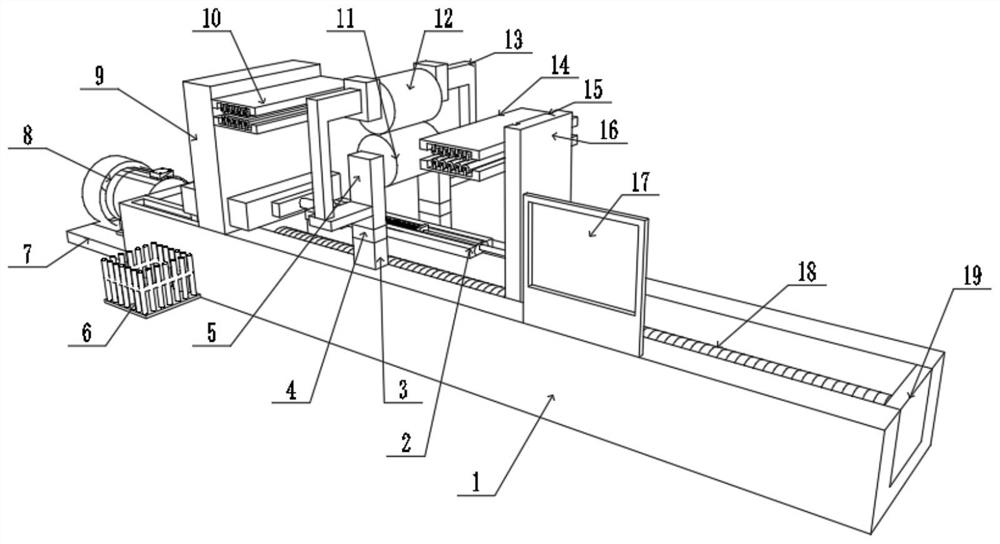

[0034] A device for testing the flatness and tensile strength of sewing parts, such as figure 1 As shown, it includes a fixed base 1, the side wall of the fixed base 1 is welded with a motor platform 7, the top of the motor platform 7 is fixed with a motor 8, and the output shaft of the motor 8 is connected with a lead screw 18 through a coupling. One end of the bar 18 is fixed with a stopper 19 through a bearing, the stopper 19 is welded to the inner wall of the fixed seat 1, the outer wall slider of the lead screw 18 is connected with a moving frame 16, and one side of the top of the fixed seat 1 is welded with a fixed frame 9 , the top of the outer wall on one side of the fixed frame 9 is provided with a fixed clamping frame 10, the top of the outer wall on one side of the moving frame 16 is provided with a mobile clamping frame 14, and a tension gauge 2 is arranged between the fixed frame 9 and the moving frame 16;

[0035] Both sides of the top of the fixed seat 1 are wel...

Embodiment 2

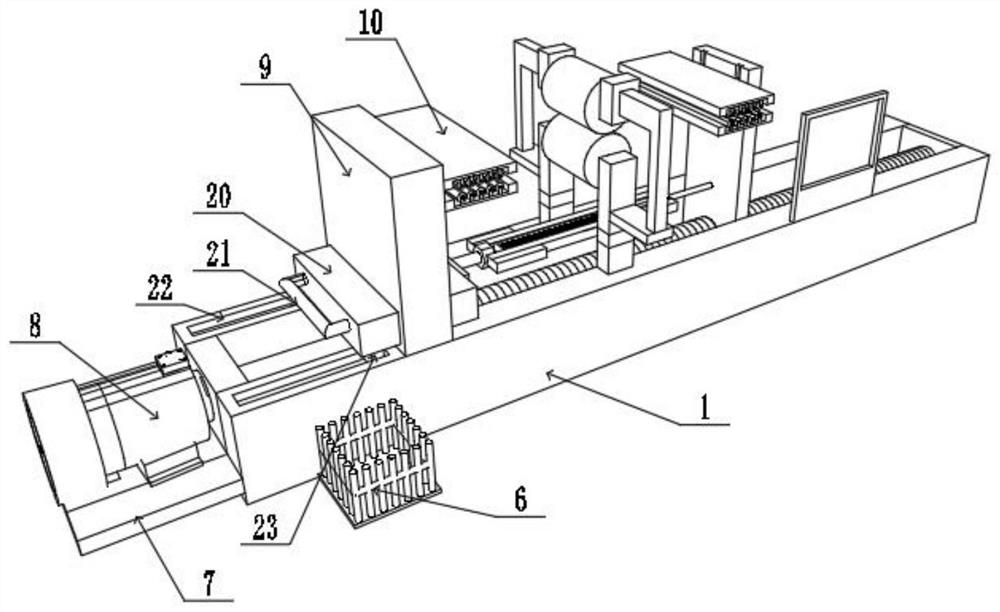

[0045] A device for testing the flatness and tensile strength of sewing parts, such as Figure 5 with Image 6 As shown, in order to solve the problem that it is inconvenient to detect the tensile strength at the corners of the cloth; this embodiment makes the following improvements on the basis of embodiment 1: one of the pillars 3 is fixed to the top of the fixed seat 1 by a hinge shaft 33, One end of another pillar 3 is fixed to the top of the fixed seat 1 by a fixed pin, and the pillar 3 can be rotated by the hinge shaft 33, so that the lower pressing roller 11 and the upper pressing roller 12 can be turned over to the fixed seat 1 side, thereby avoiding pressing down. The influence of roller 11 and upper pressure roller 12 on the detection of tensile capacity;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com