Method for real-time compensation for disturbance force on rotor in magnetic suspension bearing system

A technology of magnetic suspension bearing and real-time compensation, applied in the field of CNC machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

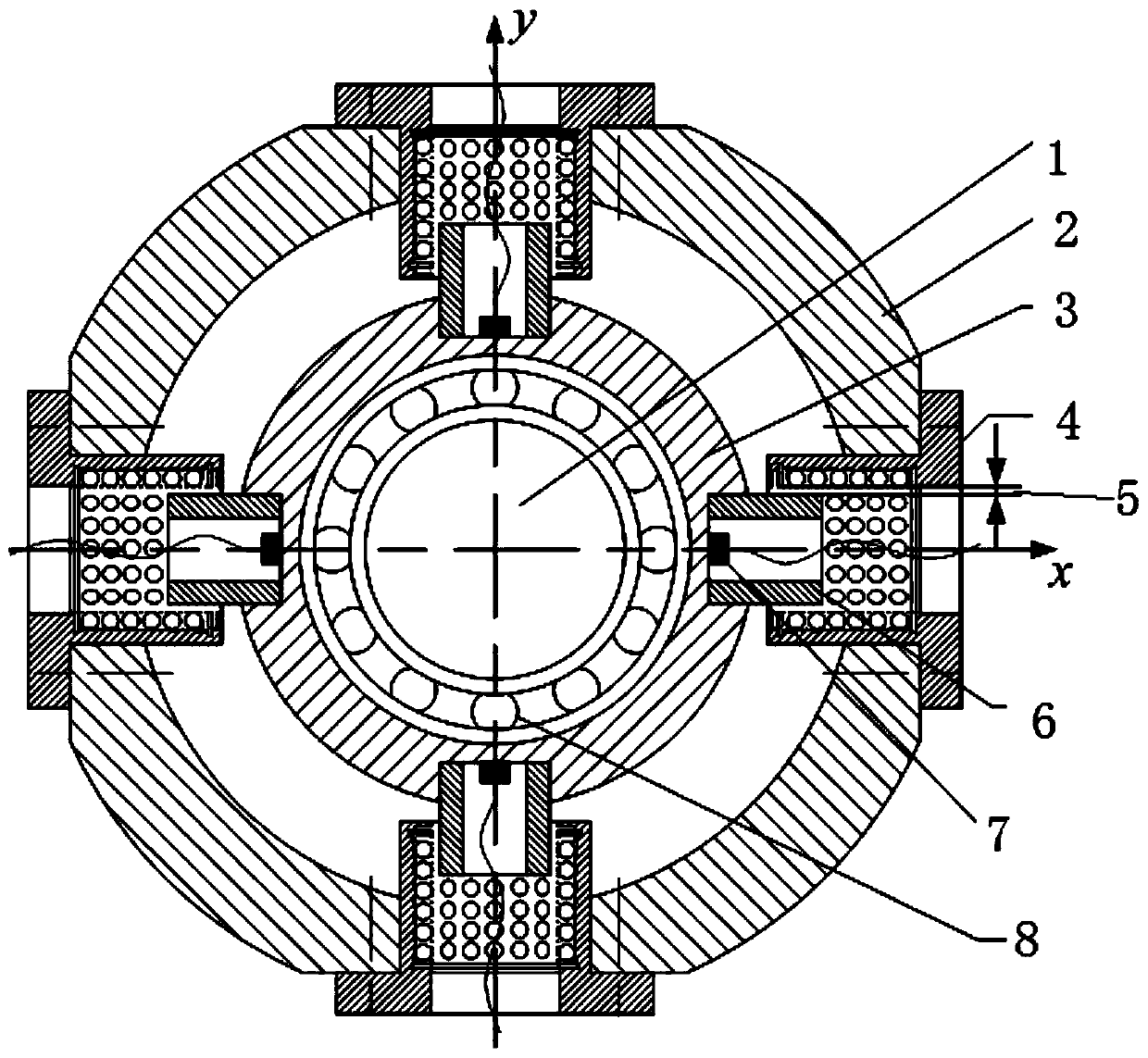

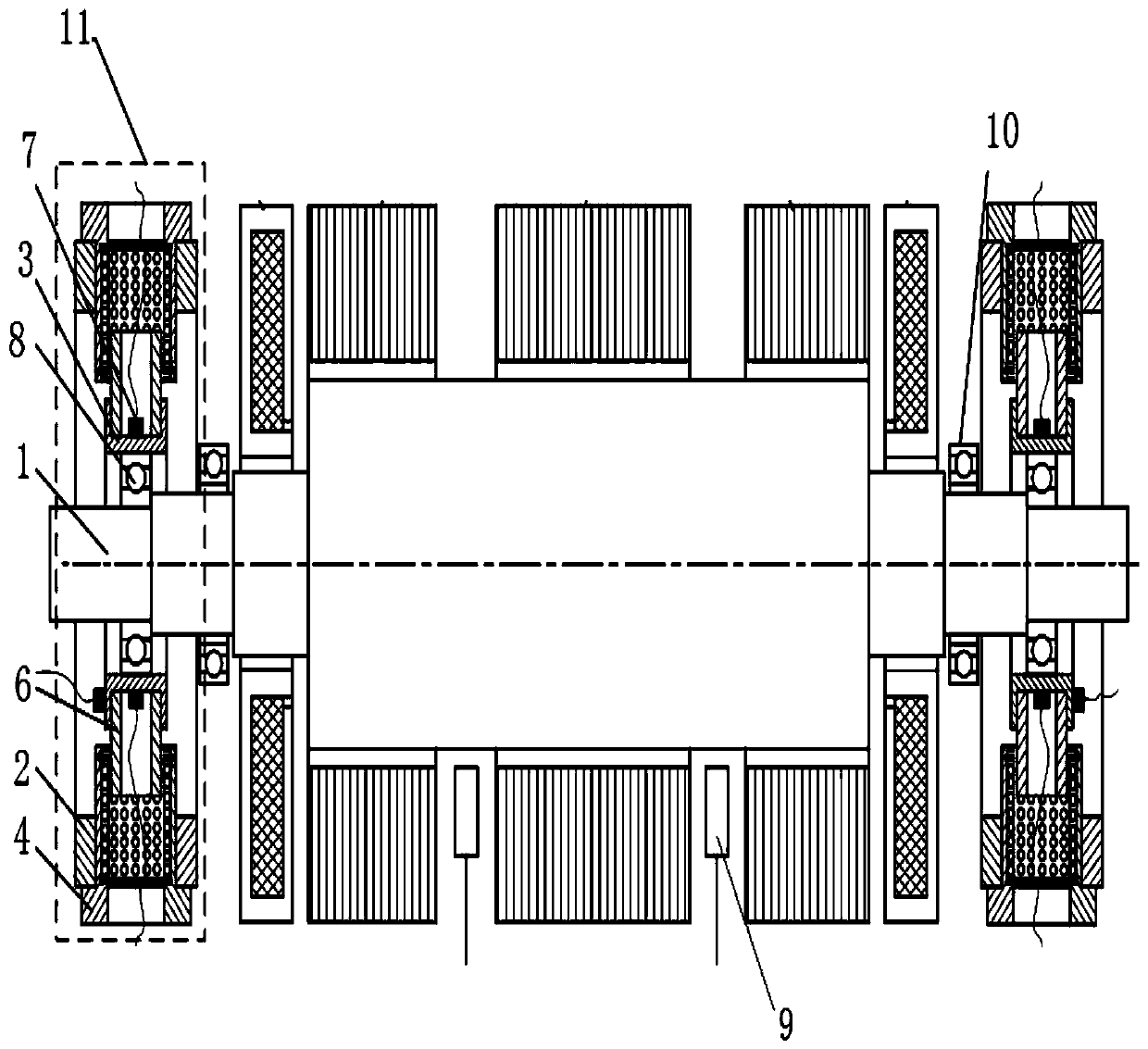

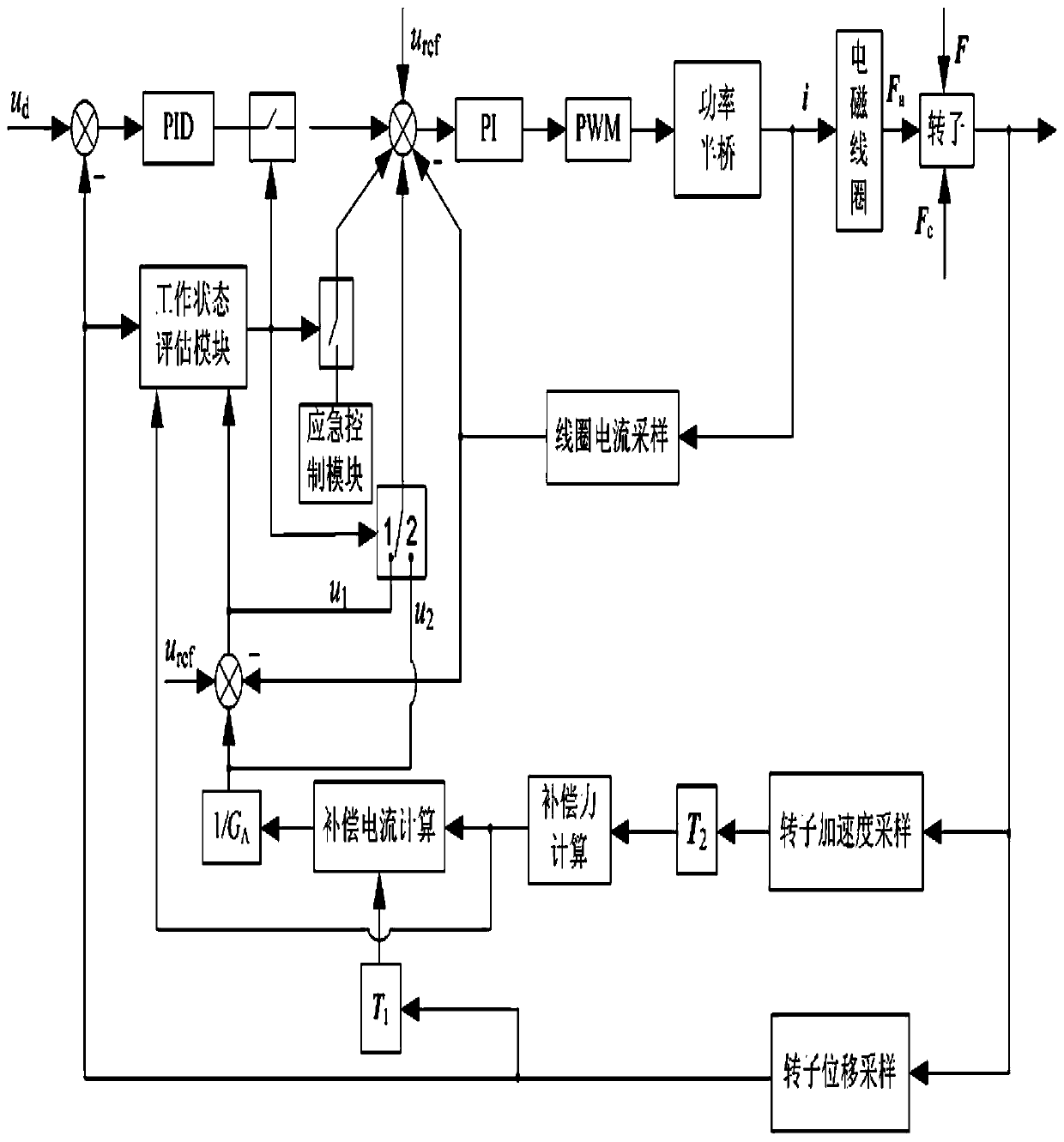

[0027] Such as Figure 1-Figure 4 A method for real-time compensation of the disturbance force suffered by the rotor in the magnetic suspension bearing system includes the following steps:

[0028] Step 1: Install the rotor vibration acceleration online detection device on the rotor of the magnetic suspension bearing system. The rotor vibration acceleration online detection device includes a ball bearing. The inner ring of the ball bearing is fixed on the rotor, and the outer ring of the ball bearing is installed on a bearing seat. The acceleration sensor is arranged on the bearing seat, and the acceleration sensor is used to detect the vibration acceleration of the bearing seat;

[0029] The acceleration sensor indirectly detects the vibration acceleration of the rotor by detecting the vibration acceleration of the bearing seat.

[0030] The ball bearing rotates at a high speed driven by the rotor. Although it does not bear load, it still generates a certain amount of heat. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com