Dust suction and noise reduction device for continuous operation of hosiery machine and method of using same

A sock machine and work technology, applied in textiles, papermaking, knitting, etc., can solve the problems of low production efficiency and maintenance frequency of hosiery machines, and achieve the effects of less quantity, lower energy consumption, and lower noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for limiting the present invention.

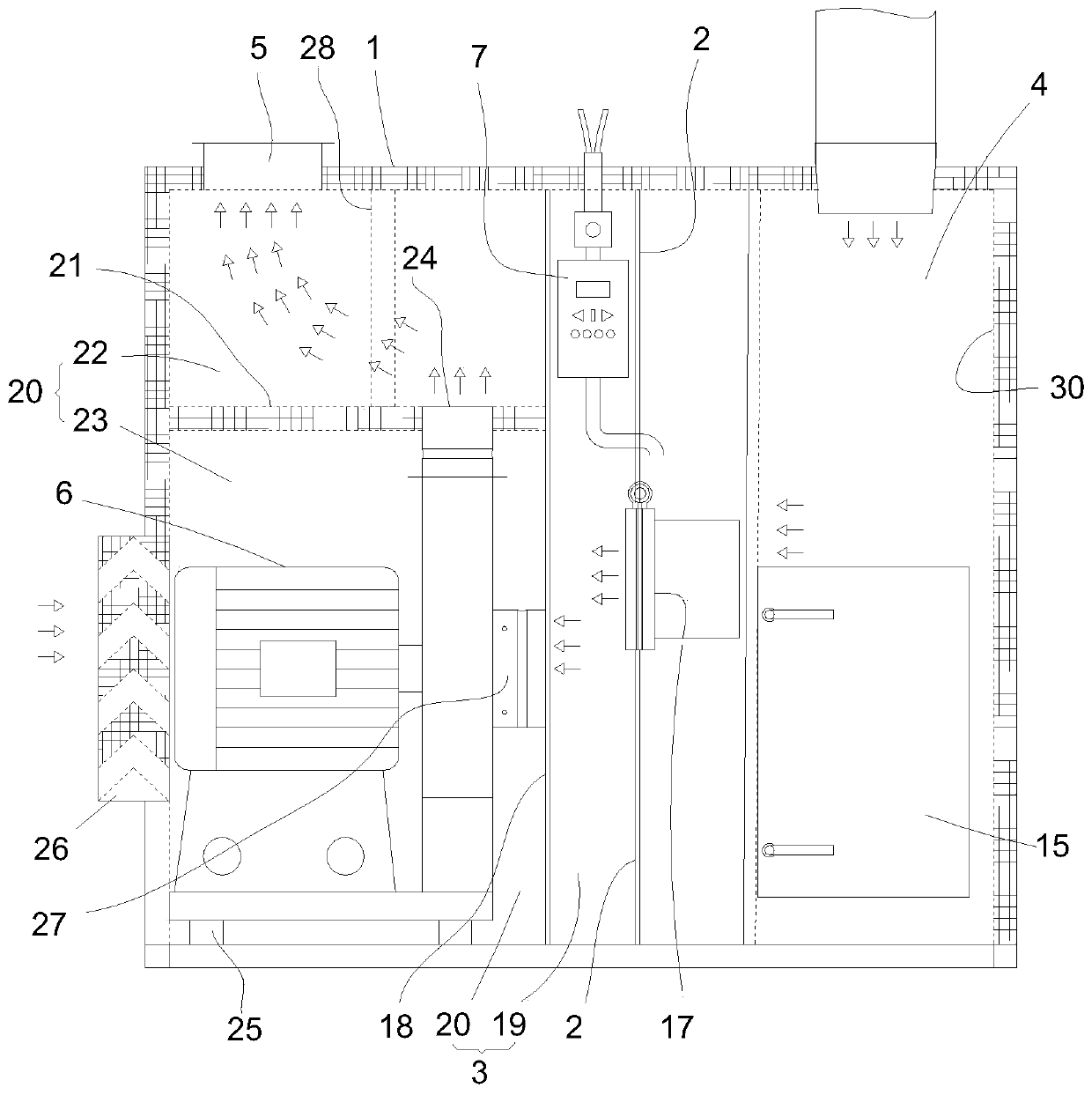

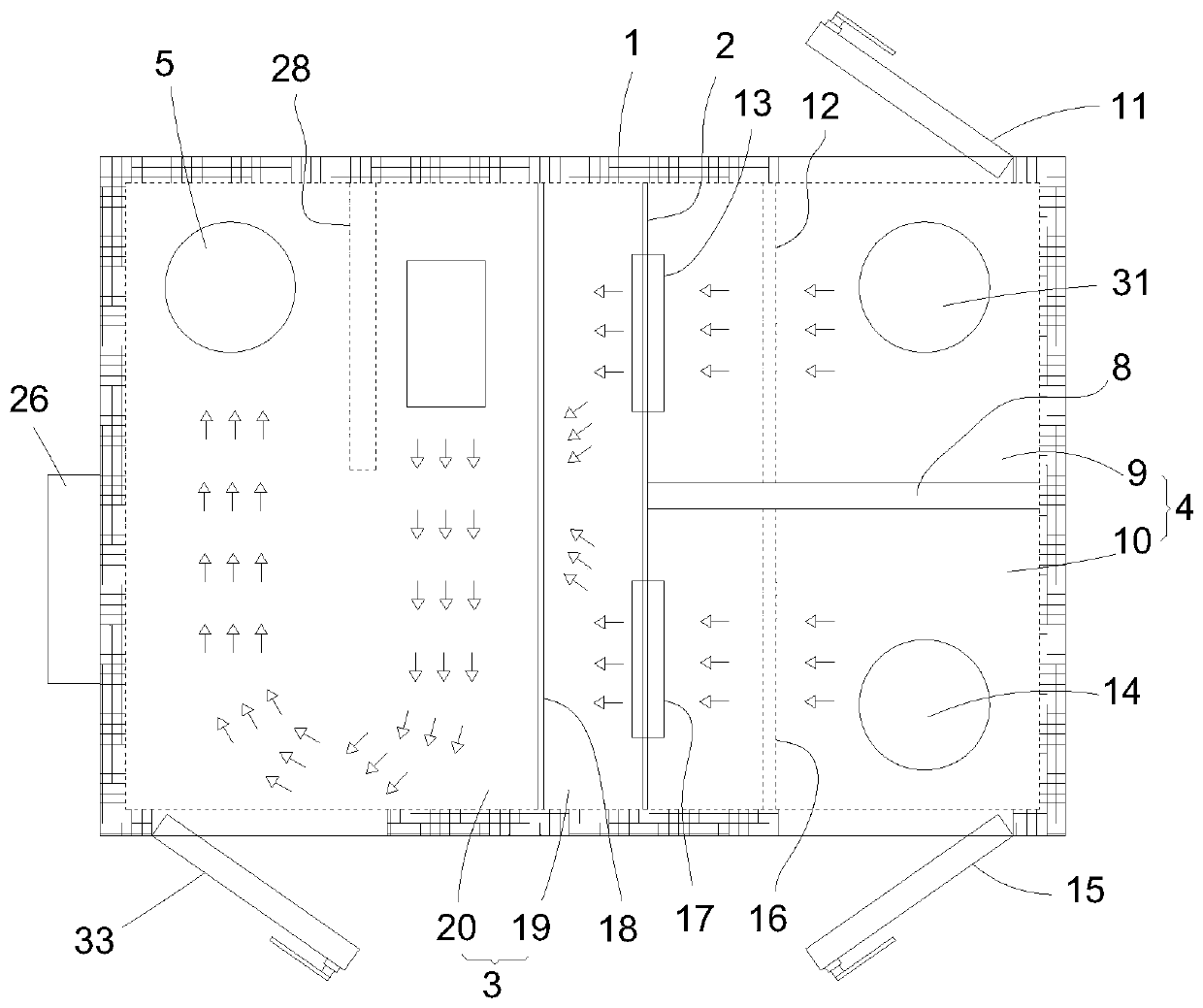

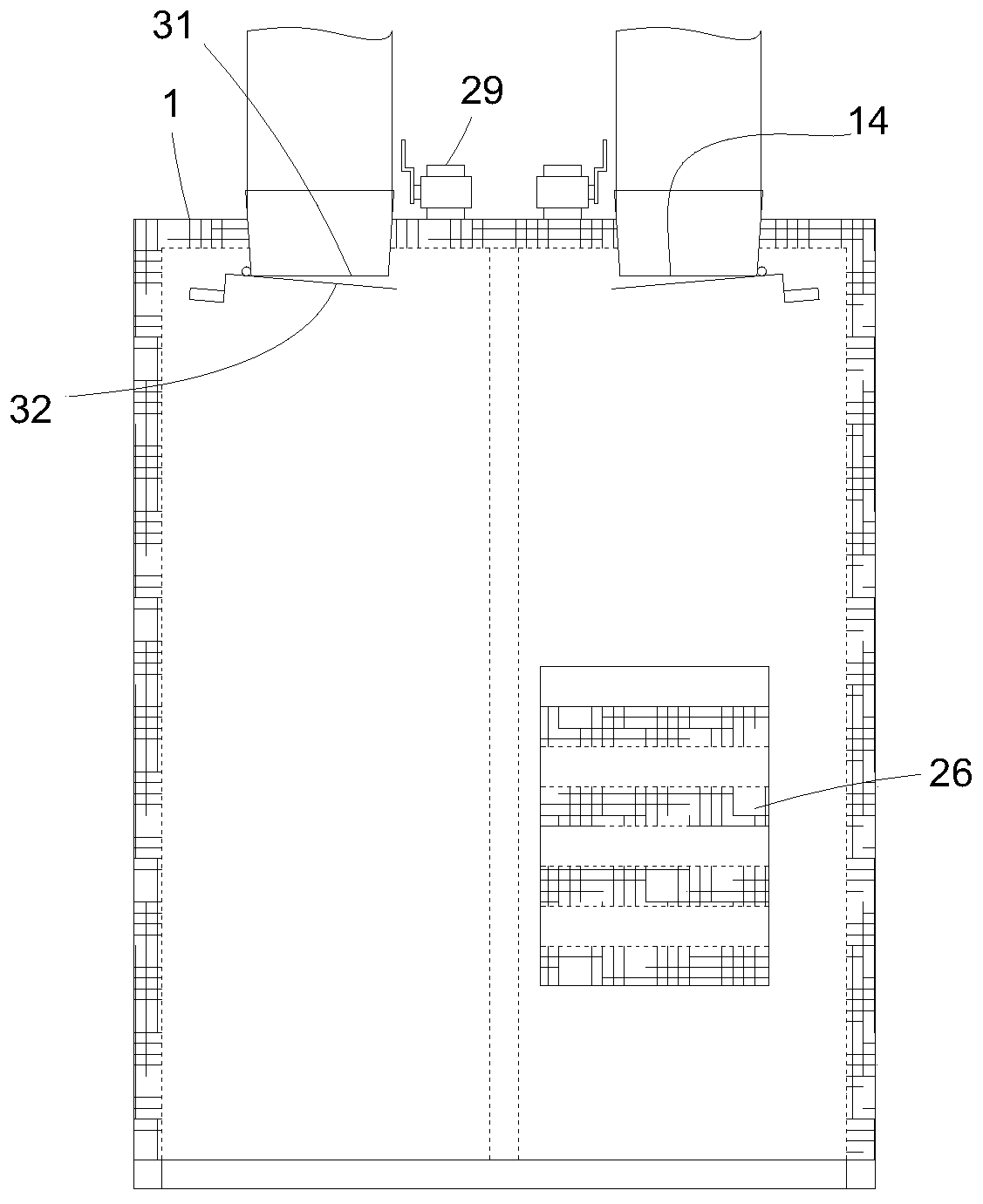

[0030] Example. Dust suction and noise reduction device for hosiery machine continuous work, such as figure 1 As shown, it includes a closed box body 1, a first partition 2 is arranged inside the box body 1, a first chamber 3 is formed on one side of the first partition 2, and a second chamber is formed on the other side of the first partition 2 chamber 4; the first chamber 3 is provided with an air outlet 5, the first chamber 3 is provided with a fan 6, and the box body 1 is provided with a frequency converter 7 connected with the fan 6; the second chamber 4 is provided with a second Two partitions 8, the second partition 8 divides the second chamber 4 into a third chamber 9 and a fourth chamber 10;

[0031] The third chamber 9 is provided with a first waste silk inlet 31 and a first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com