Threading plate bottoming device of flat knitting machine

A threading board and threading technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of inability to block the calculation of the wire conveying length, waste of resources, defective products, etc., and reduce the cost of weaving and labor. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

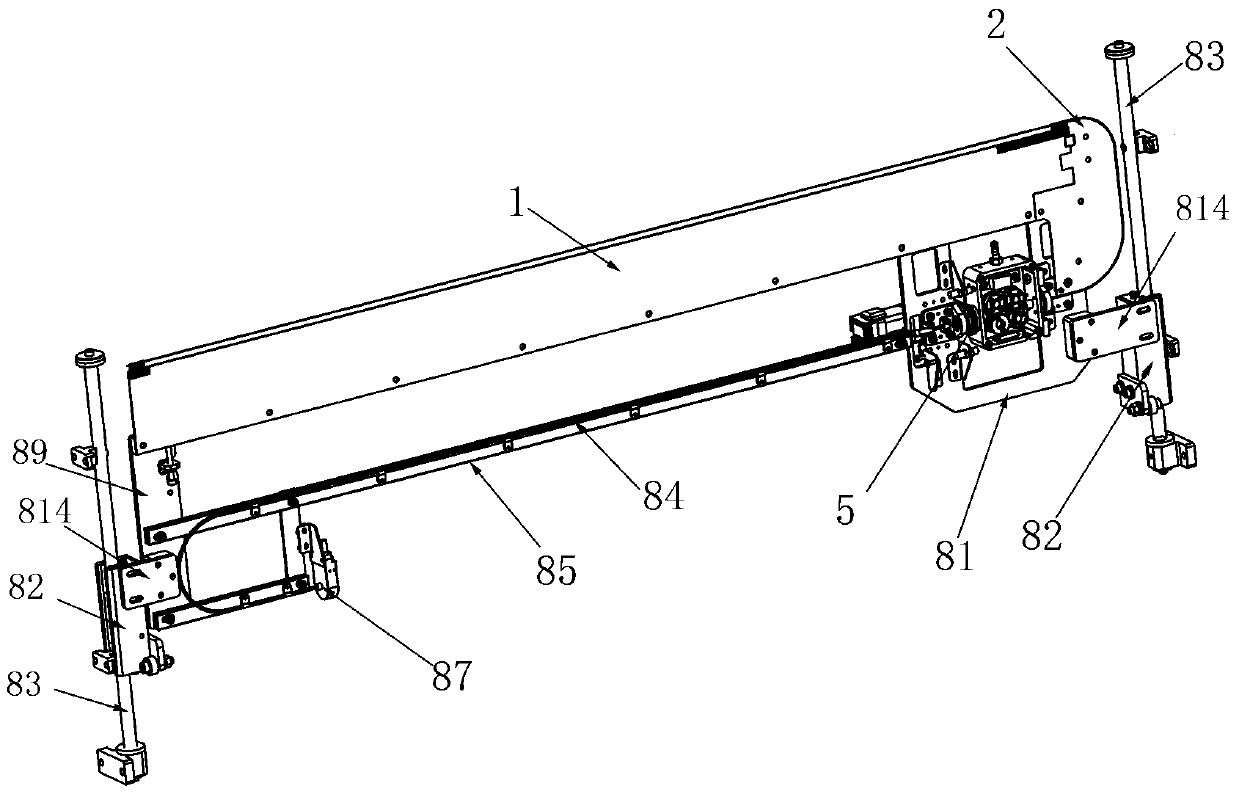

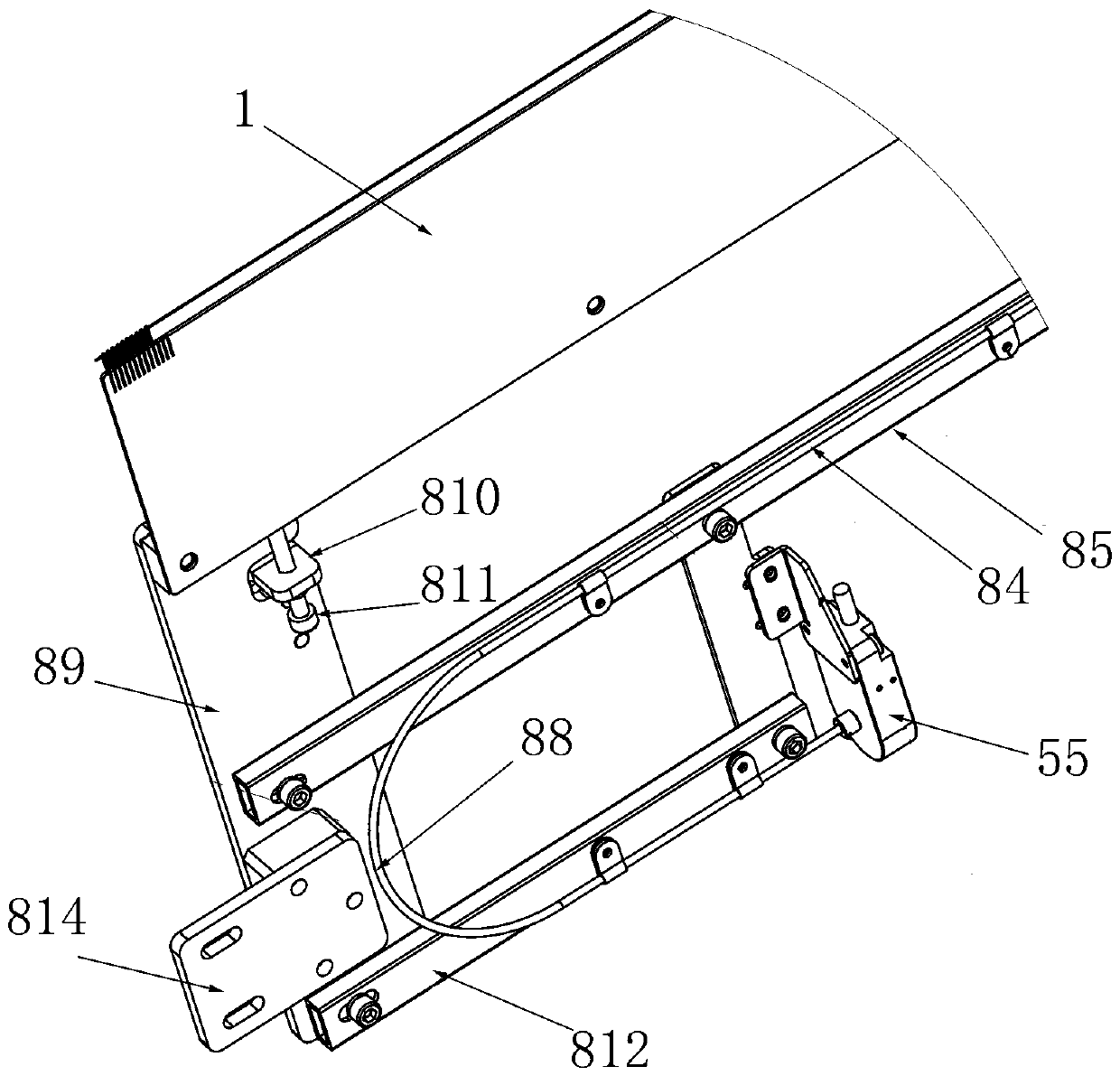

[0052] See attached picture. The lifting device described in this embodiment includes a threading plate assembly, a steel wire conveying assembly and a steel wire limiting assembly. The transmission and rotation of the steel wire is accomplished by the steel wire transmission assembly.

[0053] The threading plate assembly includes the threading plate 1, the lead plate 2 and the slotted needle plate connecting rod 3, the two ends of the threading plate assembly are installed on the left fixed plate 89 and the right fixed plate 81 respectively, and the lifting mechanism includes a linear bearing sleeve 82, a slide bar 83 and the lifting motor, the linear bearing sleeve 82 is installed on the slide bar 83, the lifting motor drives the linear bearing sleeve 82 to slide up and down along the slide bar 83, the left side fixed plate 89 and the right side fixed plate 81 are respectively installed on two sides by a connecting plate 814. On the linear bearing sleeve 82 on the side, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com