Yarn guiding device for spinning machine

A yarn guide device and mechanical technology, applied in textiles and papermaking, etc., can solve the problems of difficulty in matching the yarn drawing speed and the yarn swallowing speed, affecting the quality of yarn plying, blocking the yarn guide device, etc., so as to achieve the yarn swallowing speed. Consistent, blocking prevention, consistent yarn swallowing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

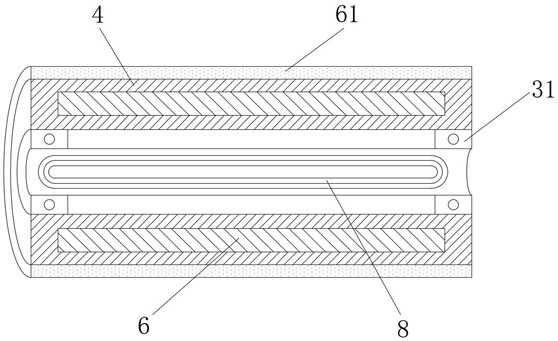

[0026] see Figure 1-3 , the present embodiment provides a yarn guide device for spinning machinery, including a fixed box 1 for installing the yarn guide equipment, material holes 2 are opened on both sides of the fixed box 1 away from each other, and the fixed box 1 is far away from the material hole 2 Both sides are equipped with freely rotatable rollers 4 through the rotating shaft 3. There are four rollers 4, and the four rollers 4 are divided into extraction groups 41 and speed change groups 42 in the same horizontal direction. The roller 4 is arranged along the vertical direction where the fixed box 1 is located.

[0027] The two ends outer walls of rotating shaft 3 are all fixed with bearing 31, and the outer wall of bearing 31 is fixed with the inwall of roller 4, and one end of rotating shaft 3 is fixed with the inwall of fixed box 1, and rotating shaft 3 is hollow cylinder type.

[0028] The extraction group 41 and the speed change group 42 are bonded with a coil 8...

Embodiment 2

[0039] see figure 1 On the basis of Embodiment 1, a further improvement is made: the bottom side of the material hole 2 is provided with a movable groove 21, and a freely rotatable roller shaft 22 is installed between the two sides of the movable groove 21 along the direction of the roller 4, The roller shaft 22 is made of ceramic material. Through the ceramic roller shaft 22, the friction force between the yarn and the material hole 2 can be reduced, the loss of kinetic energy of the motor 71 by the friction force can be avoided, and the direct contact between the yarn and the material hole 2 can be avoided. When excessive hairiness is produced, the situation that affects the quality of yarn strands occurs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com