Rigid anti-swing lifting device suitable for crane

A crane and rigid technology, applied in the direction of cranes, trolley cranes, hoisting equipment braking devices, etc., can solve the problems of difficult to solve the swaying problem, and achieve the effect of saving time and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

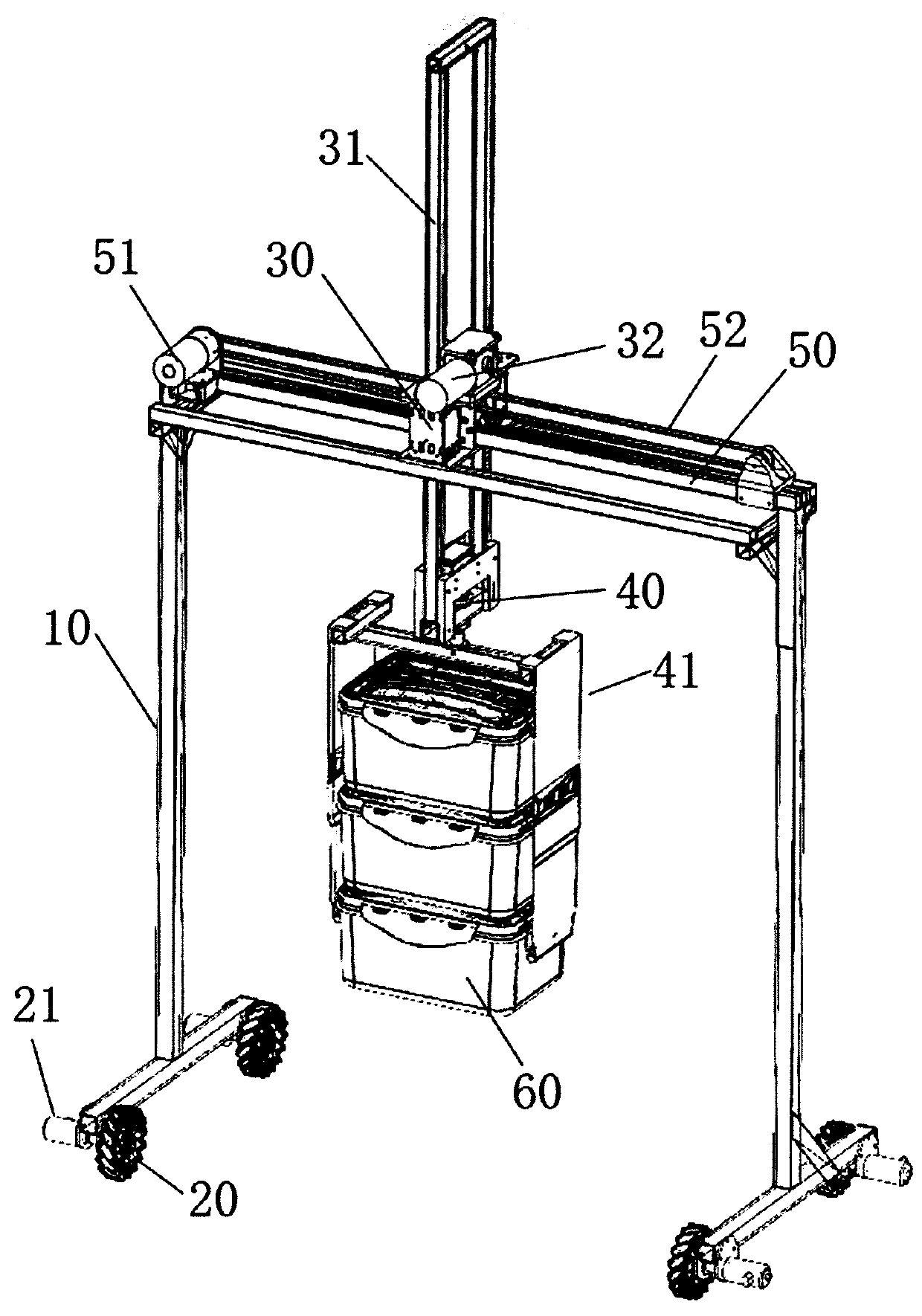

[0037] see Figure 1-6 As shown, a rigid anti-swing lifting device suitable for a crane includes a portal stabilizer 10 on which a traveling mechanism, a lifting mechanism, a translation mechanism, a grabbing mechanism, and a control module are arranged.

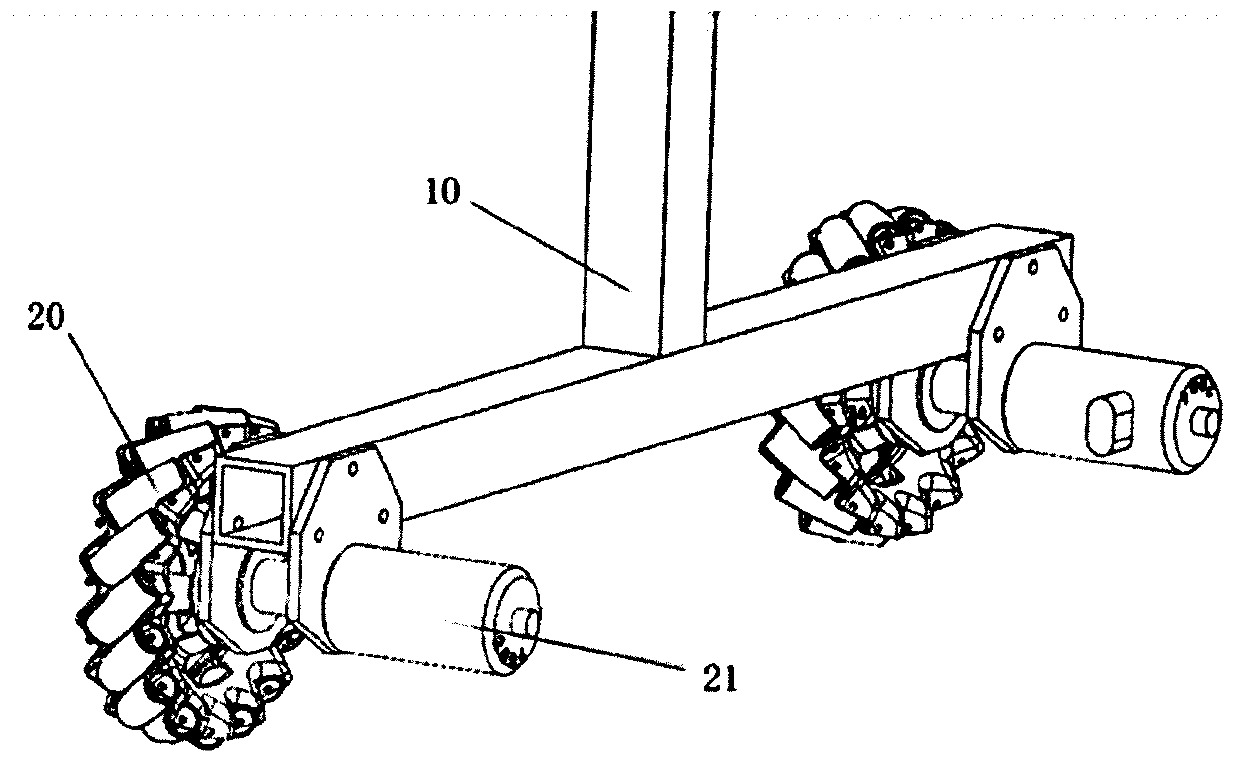

[0038] The traveling mechanism includes several mecanum wheels 20 and traveling motors 21 fixedly arranged at the bottom of the gantry stabilizer 10 , and each mecanum wheel 20 is driven and controlled by a corresponding traveling motor 21 to move in all directions.

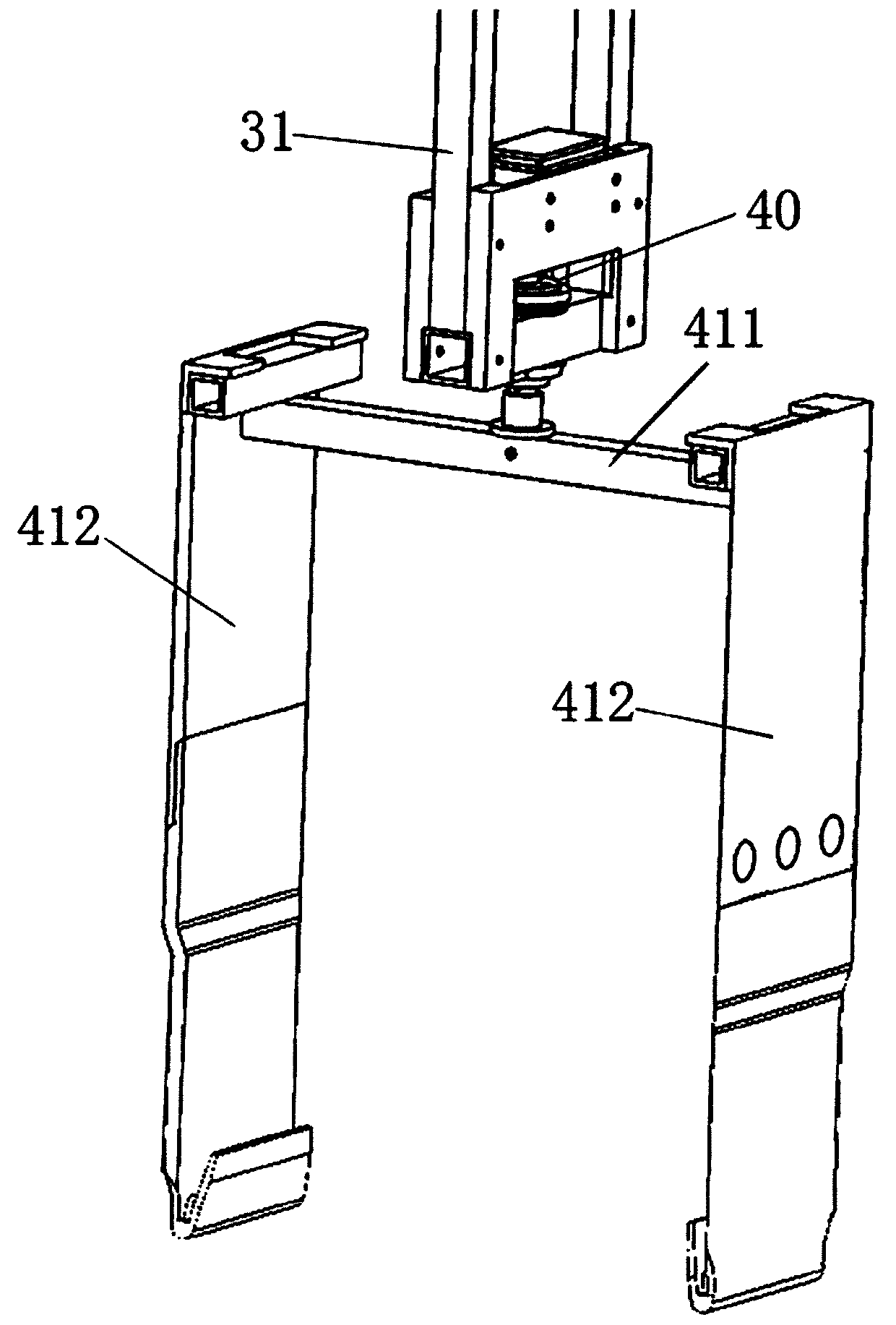

[0039] Lifting mechanism comprises sliding seat 30, lifting frame 31, lifting motor 32, wire wheel 33, steel wire rope 34; Lifting frame 31 vertically passes sliding seat 30; Slide seat 30 is assembled by several fiberglass boards. Several spacer bearings 301 are arranged around the side wall of the lifting frame 31 in the slide seat 30, and several spacer bearings 301 are mounted on the slide seat 30 by thin shaft clearance; The walls are slidingly connected,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com