Semi-automatic microcapsule forming device

A molding device and microcapsule technology, which is applied in the field of semi-automatic microcapsule molding devices, can solve the problems of three-port air shear force microcapsule devices that are prone to bacterial contamination, electrostatic microcapsule molding device technology is immature, and the cost of use is difficult to popularize. Easy to operate, low cost, great practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

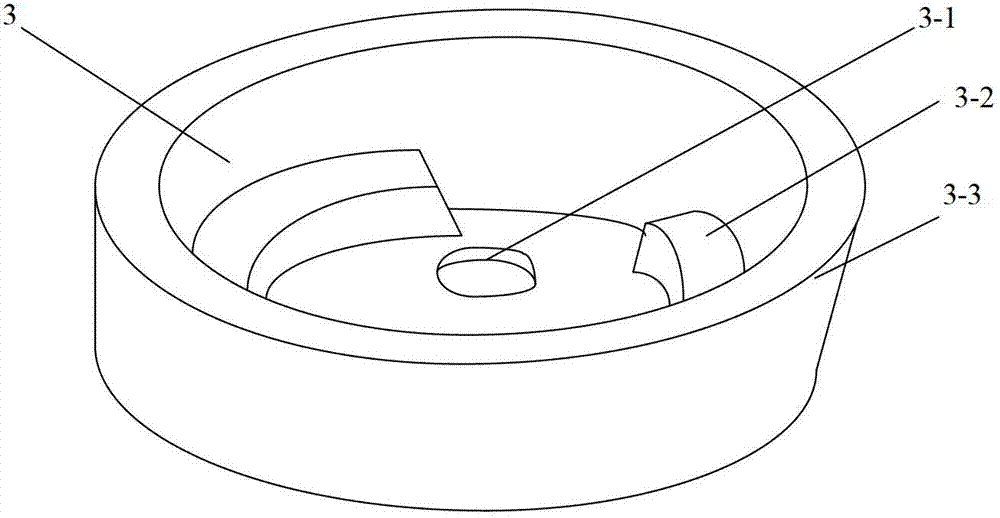

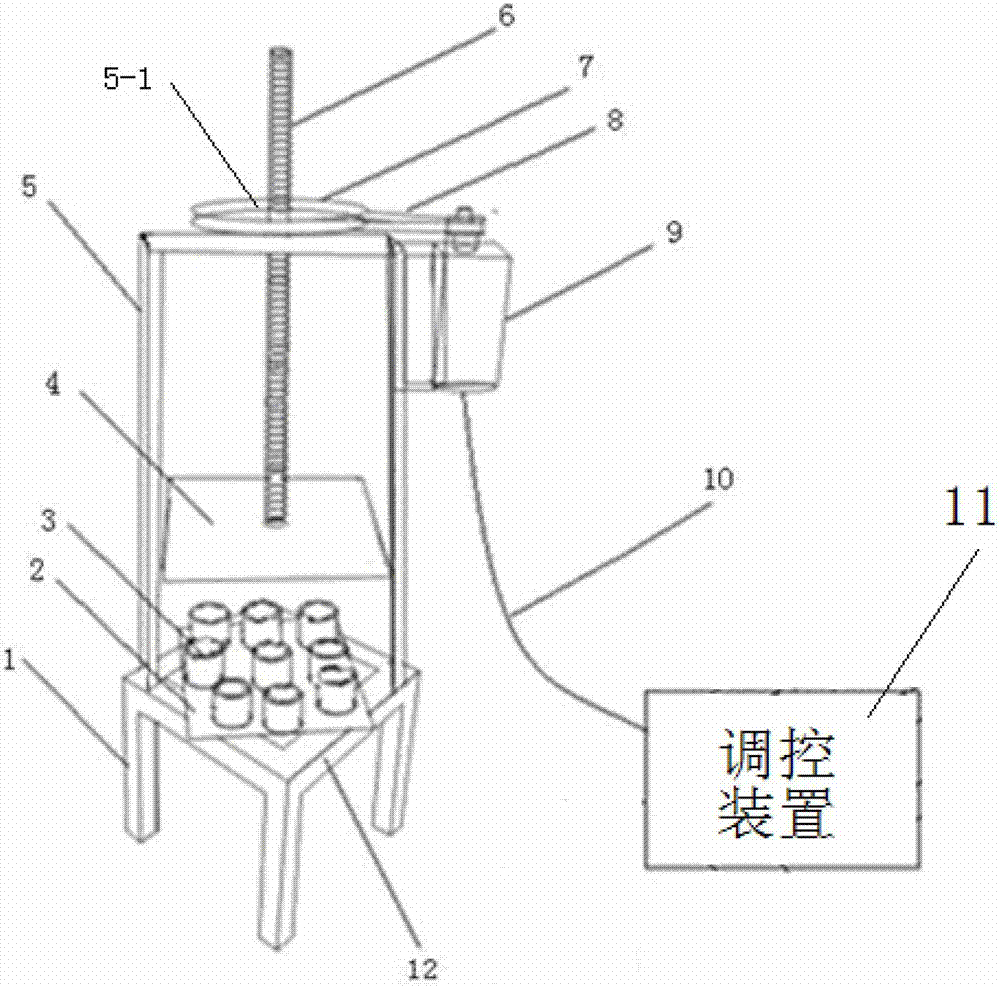

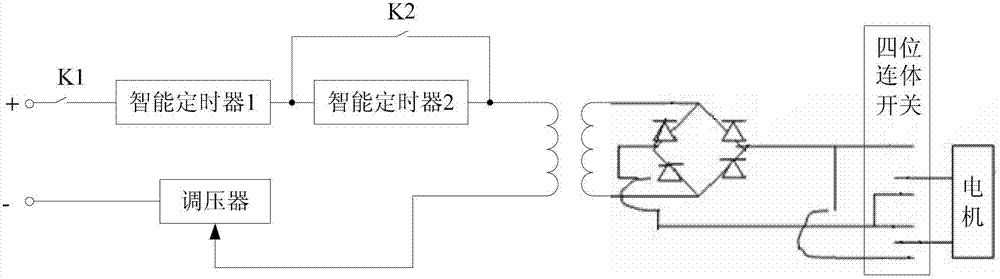

[0028] The technical solution of the present invention is composed of a program-adjustable control device 11, a single screw rod 6, a pusher plate 4, a syringe cover 3, a load-bearing frame 12, a bracket 5, and an angle iron 1. The upper end of the bracket 5 has a screw hole 5-1 and The single screw 6 is matched, the power is turned on, and the control device 11 is regulated, the motor 9 drives the belt 8 to rotate the turntable 7, the turntable 7 drives the single screw 6, the single screw 6 is welded with the pusher plate 4, and multiple needles with needles are welded together. The syringe is inserted into the syringe sleeve 3 on the support plate 2 , and the angle iron 1 and the bearing frame 12 are against the support plate 2 . When the pusher plate 4 moves downward to generate pressure on the syringe, the needle of the syringe is fixed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com