Shore power cable management device

A management device and electric cable technology, which is applied in the field of shore power cable management device, can solve problems such as potential safety hazards, and achieve the effects of avoiding friction, reducing leakage, and ensuring cable tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

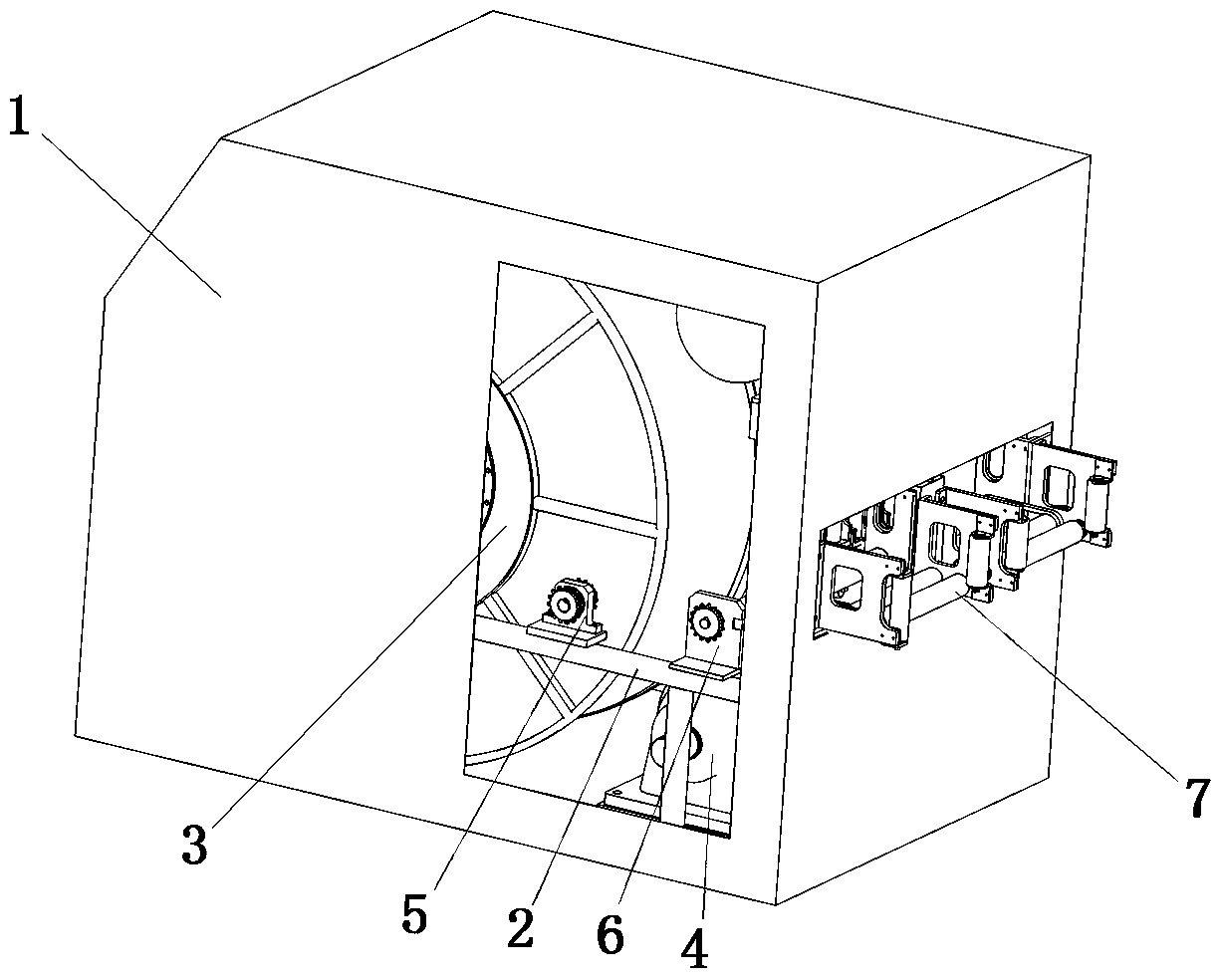

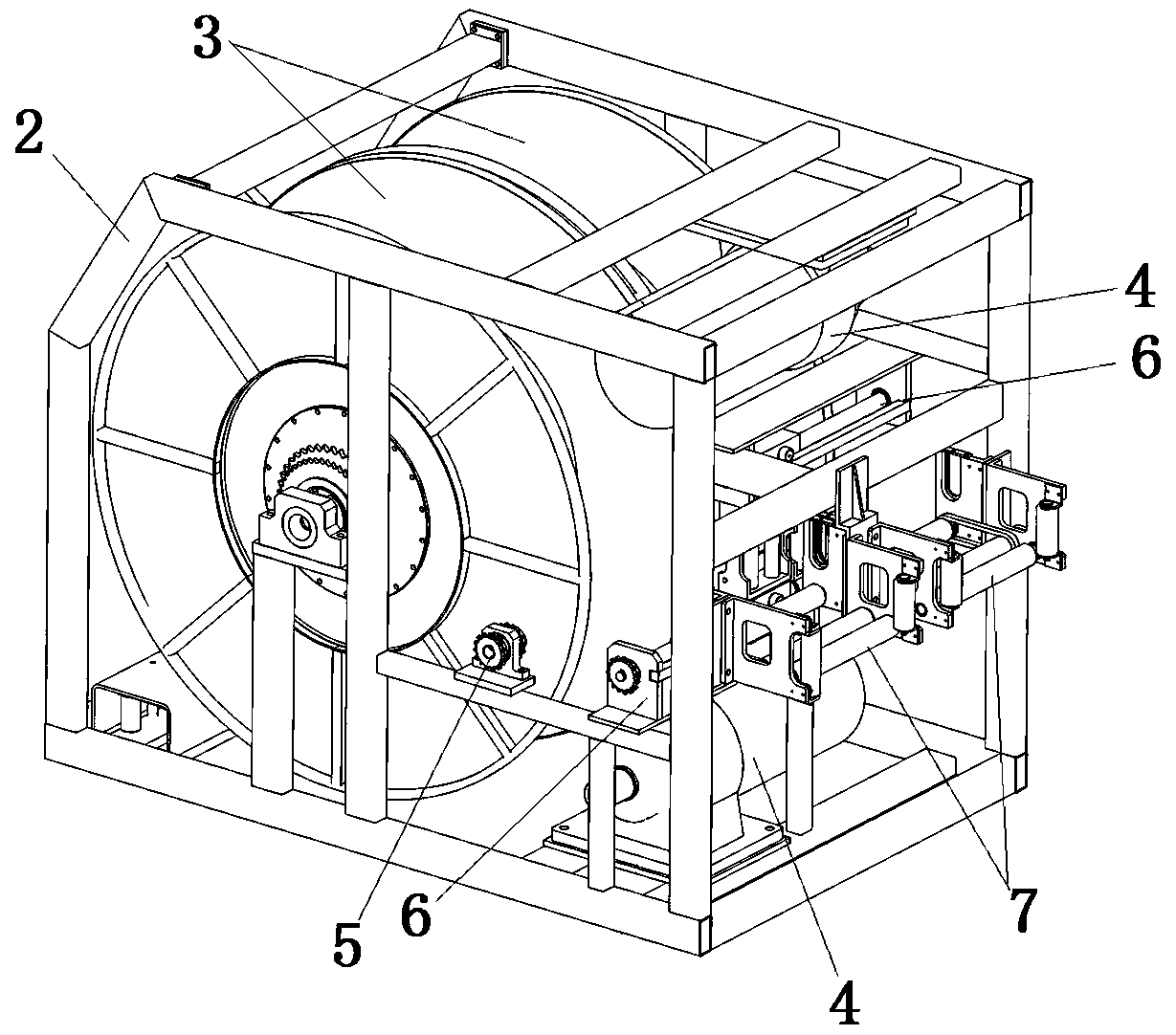

[0035] Such as figure 1 and figure 2 As shown, the shore power cable management device includes a housing 1, a mounting frame 2 and two sets of take-up and release systems. The installation basis of the pay-off system; both take-up and pay-off systems include a reel 3, a drive motor 4, an intermediate transmission mechanism 5, an automatic wire-discharging mechanism 6 and a pay-off assist mechanism 7.

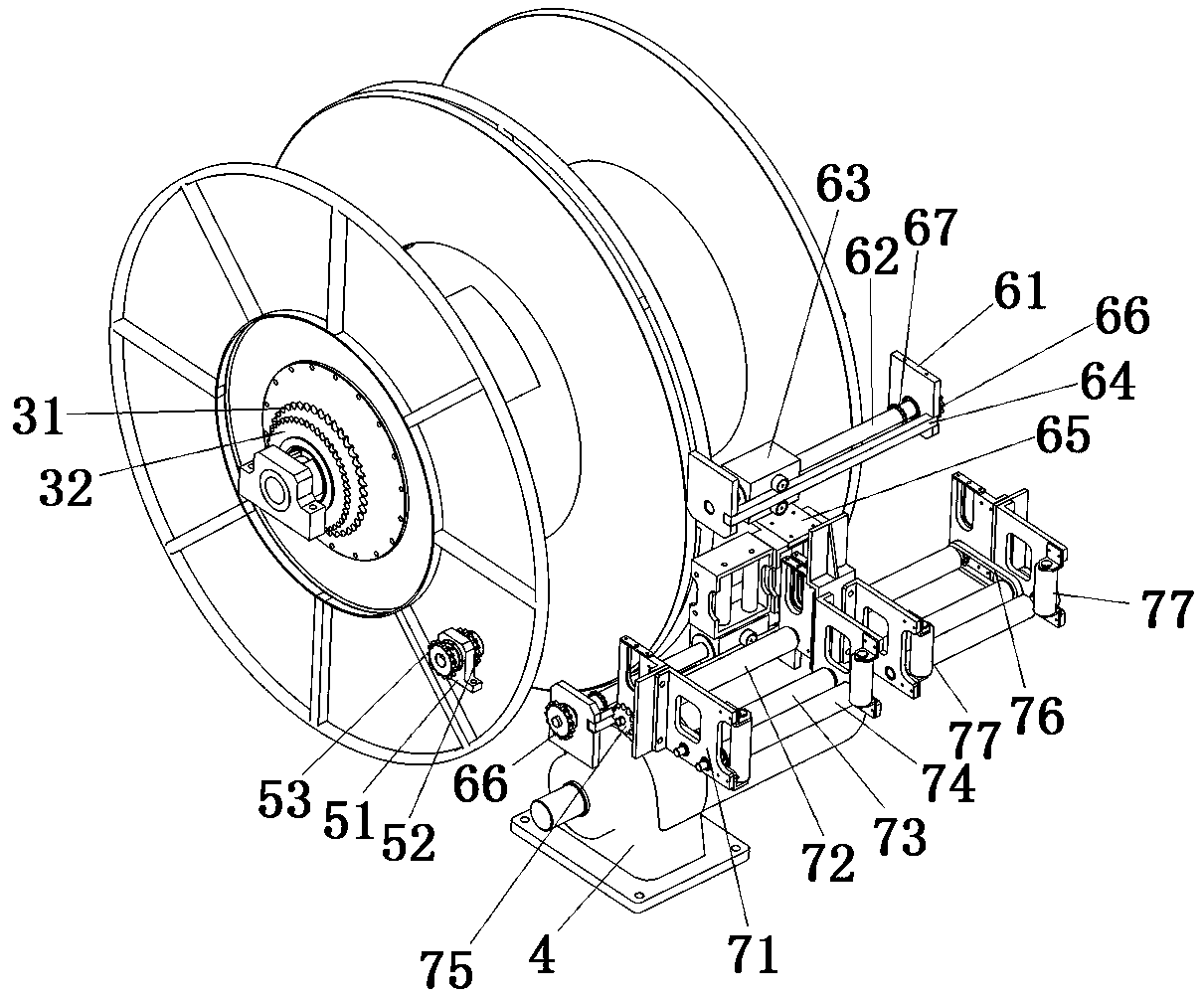

[0036] Such as Figure 1-Figure 5As shown, the reel 3 is rotatably installed on the mounting frame 2, the driving motor 4 is fixedly installed on the mounting frame 2, the reel 2 is equipped with a first reel sprocket 31, and the first reel sprocket 31 and the reel 3 The axes of rotation are collinear, and the drive motor 4 drives the reel 3 to rotate through the first reel sprocket 31 and related chains (not shown in the figure); the second reel sprocket 32 is also installed on the reel 3, and the second The drum sprocket 32 is likewise in line with the axis of rotatio...

Embodiment 2

[0047] The difference from Embodiment 1 is that the driving roller sleeve in Embodiment 2 is fixed to the driving central shaft, and there is no one-way clutch between the two, but the sprocket matched with the power-assisted chain on the driving central shaft and A one-way clutch is set between the active central shafts. The one-way clutch is combined when the reel is unwound and disconnected when the reel is taken up. In this way, it can also ensure the connection between the pay-off assist mechanism and the reel when the reel is unwound. The cable is under tension.

Embodiment 3

[0049] The difference from Example 1 is that in this Example 3, no active central shaft is set, and the active roller cover is replaced by a solid active solid roller. The power-assisted chain drives the active solid roller to rotate, and a one-way clutch is set between the sprocket on the active solid roller and the active solid roller. The one-way clutch is combined when the reel is unwound and disconnected when the reel is taken up; the active solid roller The distance between the driven roller sleeve and the driven roller sleeve ensures that the two can clamp the cable, which can also ensure that the cable between the pay-off assist mechanism and the reel is in a tensioned state when the reel is unwound.

[0050] In each of the above-mentioned embodiments, between the drive motor and the reel, between the reel and the intermediate transmission mechanism, between the intermediate transmission mechanism and the automatic wire unwinding mechanism, between the automatic wire un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com