Hydraulic-mechanical combined baking system for articulated explosion-proof vehicle in coal mine

An explosion-proof vehicle, combined braking technology, applied in the direction of brakes, brake components, vehicle components, etc., can solve the problems of brake overheating, reduced braking efficiency, inability to take away brake friction heat in time, etc., and achieve smooth and stable transformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

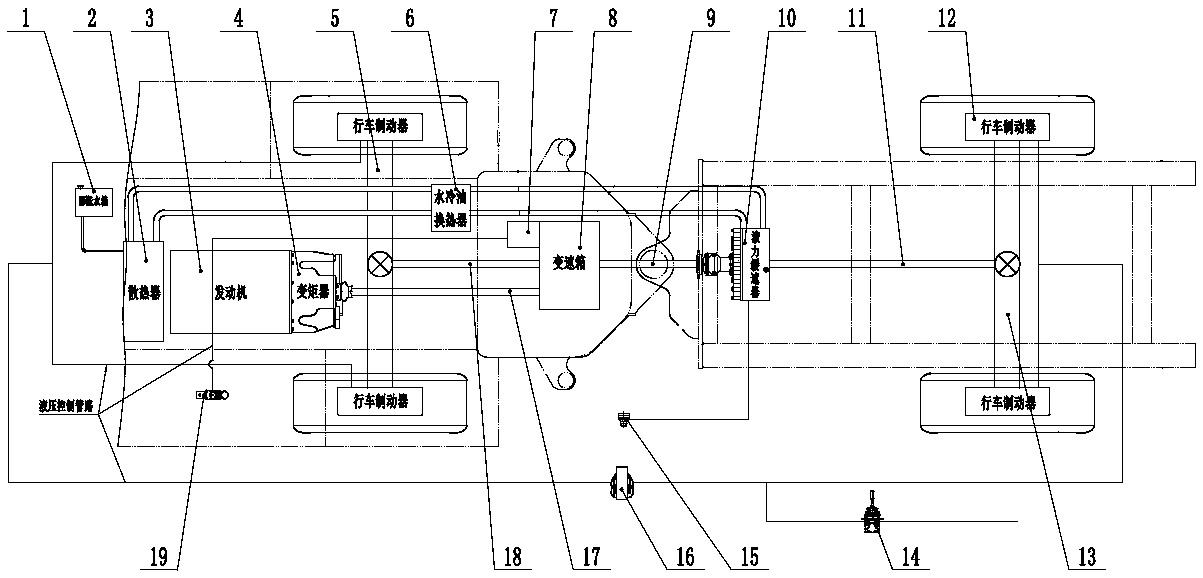

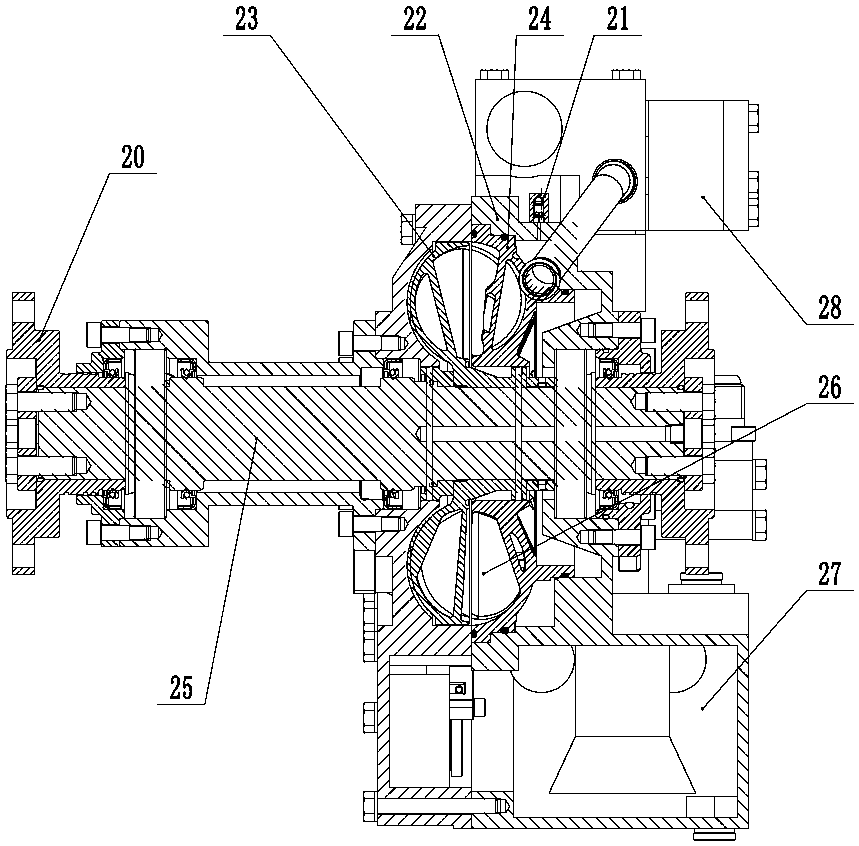

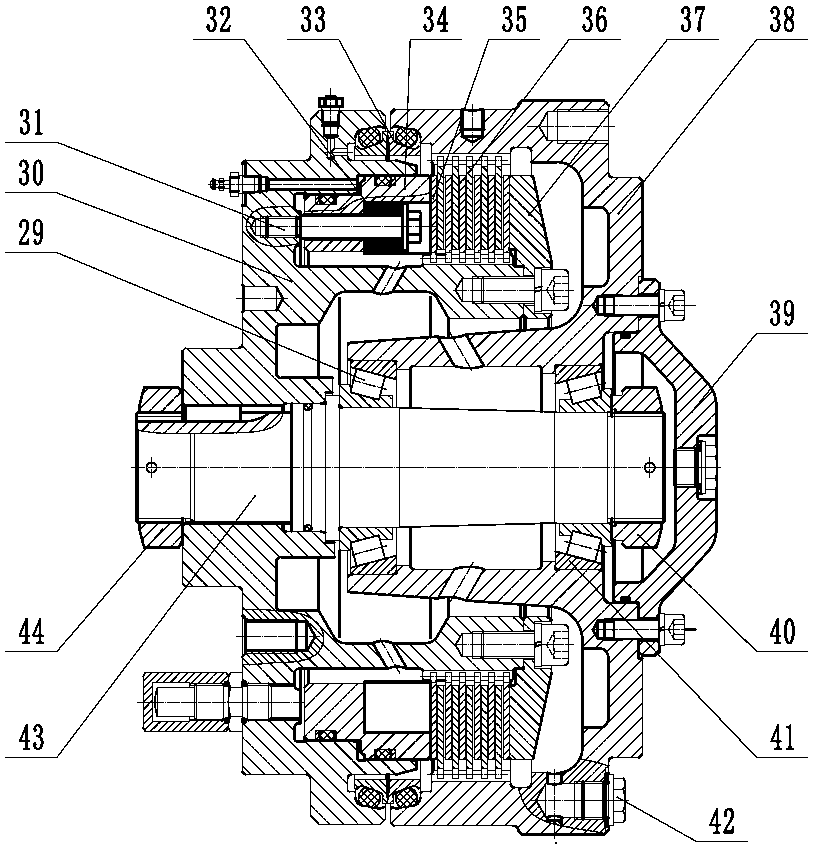

[0026] The present invention relates to a hydraulic-mechanical combined braking system for coal mine articulated explosion-proof vehicles, such as figure 1 As shown, it is characterized in that the system can realize two functions of hydraulic damping brake and mechanical friction brake. The combined effect of the two brake functions can be applied to coal mine articulated explosion-proof vehicles, which can effectively improve the performance of vehicles under different operating conditions. , especially the vehicle braking safety, reliability, ride comfort and handling comfort under long-distance and large-slope conditions. The system mainly includes a hydraulic retarding brake device for hydraulic damping braking, a wet service brake and a parking brake for mechanical friction braking, a hydraulic control system for controlling the combined brak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com