Disassembling and assembling tool and disassembling and assembling method for coupler in narrow space of large-scale submerged long-axis pump

A technology of couplings in a narrow space, which is applied in the field of disassembly tools for couplings in a small space of large submerged long-axis pumps, can solve the problems of unstable center of gravity, damage to personnel and equipment, and inability to use lifting tools, etc., to achieve Reduce the time left unavailable, reduce the risk of objects falling, reduce the effect of unavailable time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

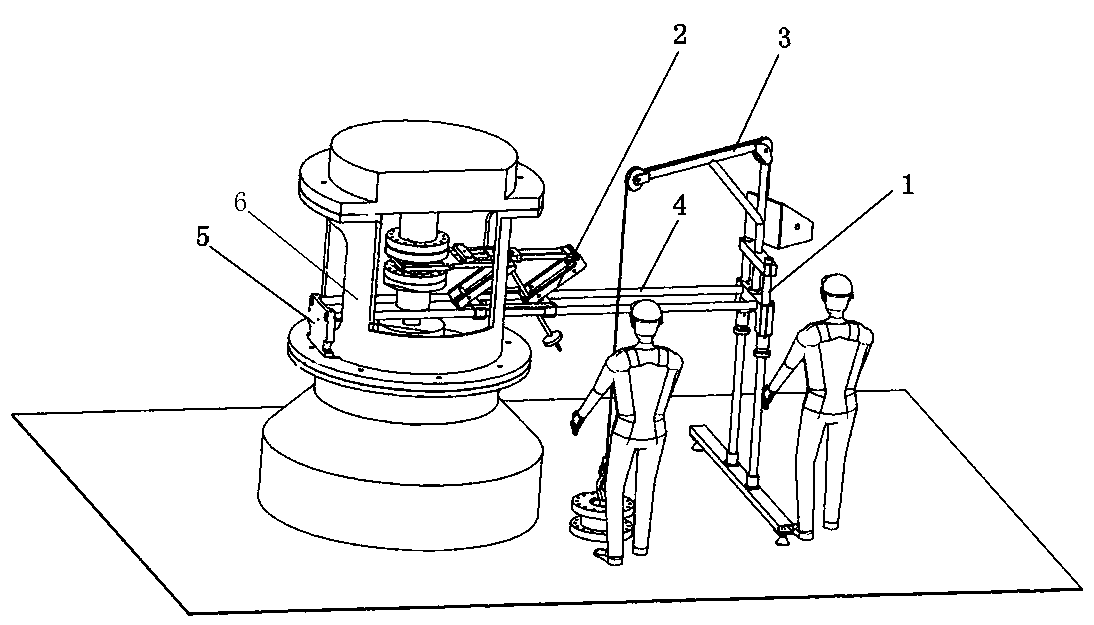

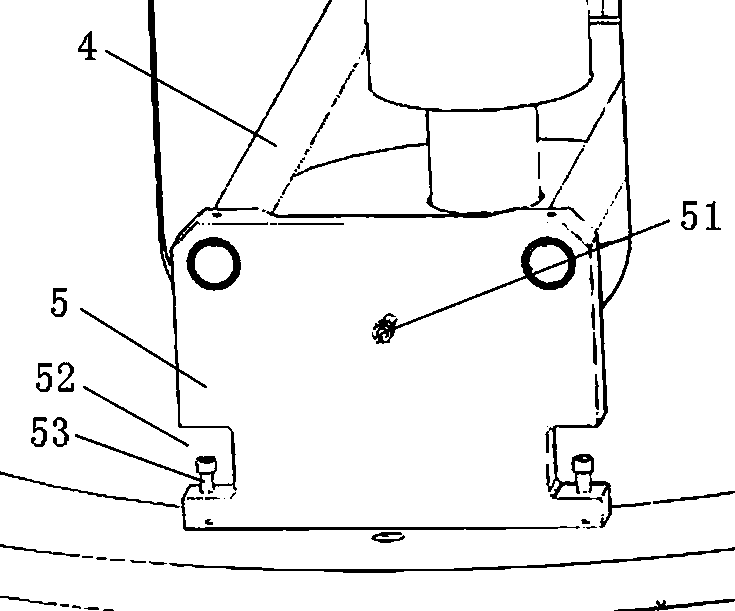

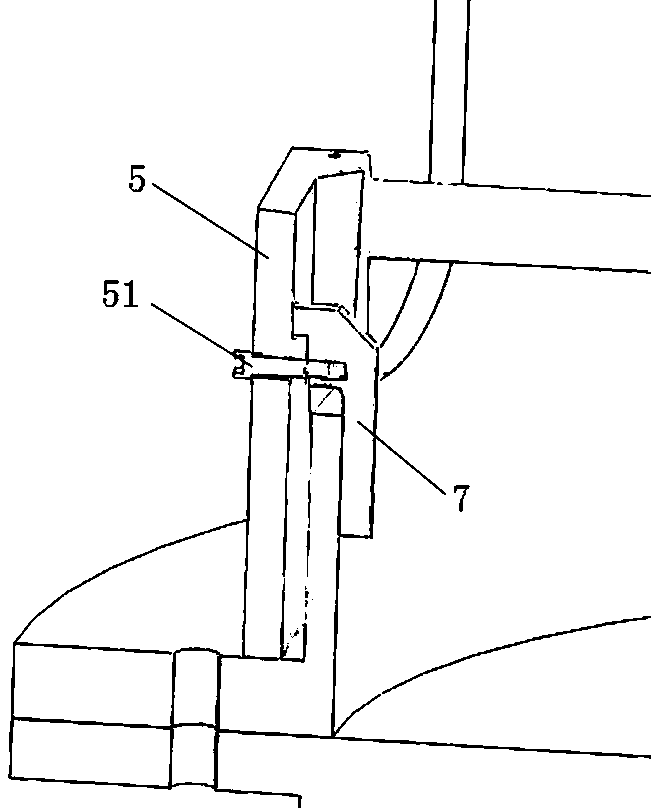

[0046] Such as figure 1 As shown, the present invention provides a coupling disassembly tool in a small space of a large-scale submerged long-axis pump, which mainly includes three parts: a support frame 1 , a lifting platform 2 , and a cantilever crane assembly 3 . Wherein, the support frame 1 is installed and connected with the motor bracket coupling protective cover 6 through the horizontal slide rail 4 and the slide rail vertical plate 5, and the horizontal slide rail 4 passes through the entire protective cover from the opening of the protective cover and passes through the slide rail vertical plate 5. Connected with the protective cover, the lifting platform 2 is slidably connected to the horizontal slide rail 4 , and the cantilever crane assembly 3 is arranged on the upper part of the support frame 1 . It should be noted that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com