Vibrating sieving machine with muting box

A technology of silent box and vibrating screen machine, which is applied in the direction of filter screen, electromechanical device, casing/cover/support, etc., which can solve the problem of affecting the normal work of the operator of the vibrating screen machine, damaging the auditory function of the operator, and not appearing in the vibrating screen. Machine and other problems, to achieve the effect of good mute effect, convenient renovation and installation, and reduce noise transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

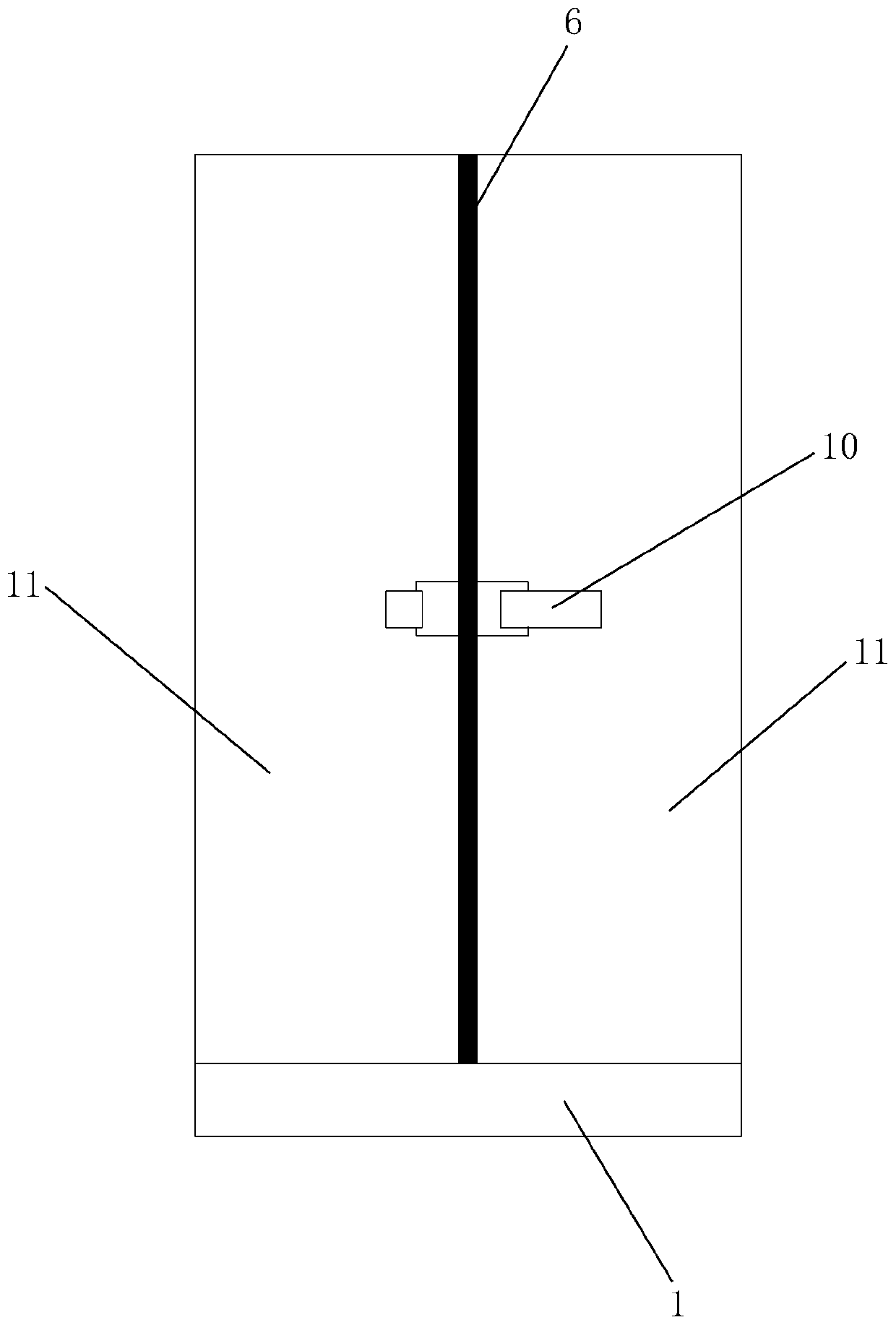

[0031] Such as Figure 1 to Figure 6 As shown, the present invention includes a silent box and a vibrating screen machine host 4 installed in the quiet box. The quiet box includes a base 1 and two sound-insulating half-casings 11, and the two sound-insulating half-casings 11 are symmetrically installed on On the top of the base 1, the cross-sectional shape of the sound-insulating half-box 11 is U-shaped, the openings of the two sound-insulating half-boxes 11 are oppositely arranged, and the front sides of the two sound-insulating half-boxes 11 pass through the lock 10 connection, the rear top of the base 1 and the joint between the two soundproof half boxes 11 are vertically provided with a fixed column 7, the bottom of the fixed column 7 is fixedly connected with the rear top of the base 1, two The rear side of the soundproof half box 11 is hinged with the fixed column 7 through a plurality of hinges 8, one side of the hinge 8 is fixedly connected with the outer side of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com