Electric double-head counter-rolling toothbrush head structure

A double-headed, electric technology, used in dentistry, cleaning teeth, medical science and other directions, can solve the problems of easy collision with teeth, damage to the inner wall of the oral cavity, and affect the comfort of brushing, so as to improve the comfort of use, improve the comfort of brushing, Reduces the effect of constant friction against the walls of the mouth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

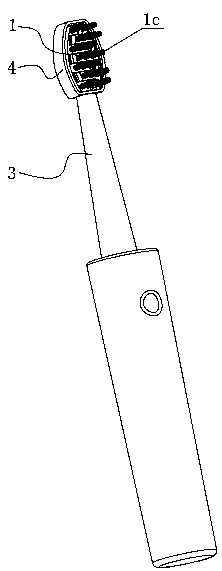

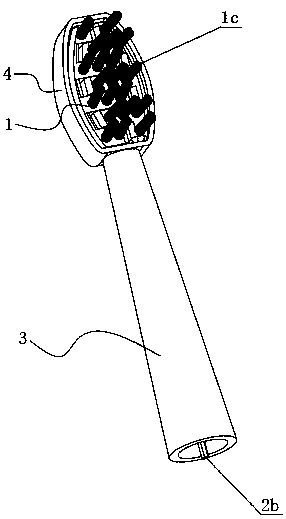

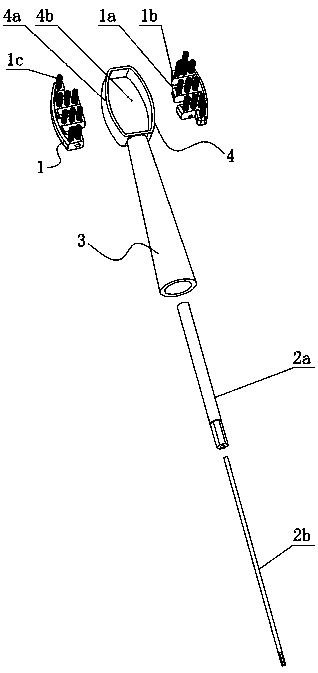

[0040] See Figure 1-3 As shown, in the brush head structure of the electric double-ended rolling toothbrush involved in this embodiment, the aforementioned transmission component includes a hollow shaft 2a and a central shaft 2b, the hollow shaft 2a and the central shaft 2b are coaxially arranged, and the hollow shaft 2a The top of the brush head is connected to a brush head body 1, the central shaft 2b is penetrated in the hollow shaft 2a and its top end protrudes from the top of the hollow shaft 2a and is connected to another brush head body 1. By driving the hollow shaft 2a and the central shaft 2b reciprocating rotation in opposite directions can drive the two brush head bodies 1 to perform reciprocating rolling motion. It should be noted that the present invention does not involve an improvement in how to drive the hollow shaft 2a and the central shaft 2b to reciprocate in opposite directions. The means for the direction reciprocating rotation will not be repeated here....

Embodiment 2

[0044] Unlike Examples 3-4, see Figure 4-6 As shown, in this embodiment, the transmission component includes a transmission shaft 2c, which penetrates into the inner cavity of the brush neck 3, the top end of the transmission shaft 2c is provided with a guide groove 2c1, and the bottom end of each brush head body 1 is provided with a guide groove 2c1. Each is connected with a transmission rod 2d, and the guide grooves 2c1 are connected end to end in a closed shape and are eccentrically arranged relative to the transmission shaft 2c (it can be understood that the axis of the transmission shaft 2c is located in the area surrounded by the guide groove 2c1, but the guide groove 2c1 The center is not in the same position as the axis of the transmission shaft 2c), the transmission rod 2d is inserted into the guide groove 2c1 downward, when the transmission shaft 2c rotates, the side wall of the guide groove 2c1 pushes against the transmission rod 2d and drives the transmission rod 2...

Embodiment 3

[0048] The difference between this embodiment and Embodiment 2 is mainly that the structure of the transmission mechanism driving the brush head body 1 to rotate is different. For details, see Figure 7-9 shown (the aforementioned bristles 1c are Figure 7-9 (not shown in the figure), the transmission component includes a crankshaft 2e, the crankshaft 2e is penetrated into the inner cavity of the brush neck 3, the bottom end of the brush head body 1 is connected with a connecting rod 2f, and the connecting rod 2f is provided with a strip hole 2f1, The top end of the crankshaft 2e passes through the bar-shaped hole 2f1 of one connecting rod 2f and is inserted into the bar-shaped hole 2f1 of the other connecting rod 2f. When the crankshaft 2e rotates, the outer peripheral surface of the crankshaft 2e pushes against the side wall of the bar-shaped hole 2f1 And drive the connecting rod 2f to swing reciprocatingly with the corresponding connecting shaft 5 as the center, and then d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com