A Probe for Ultrasonic Testing of Air Duct Electron Beam Welds

An electron beam welding seam and air duct technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, and measuring devices. problems, to achieve reliable detection results, significant economic benefits, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

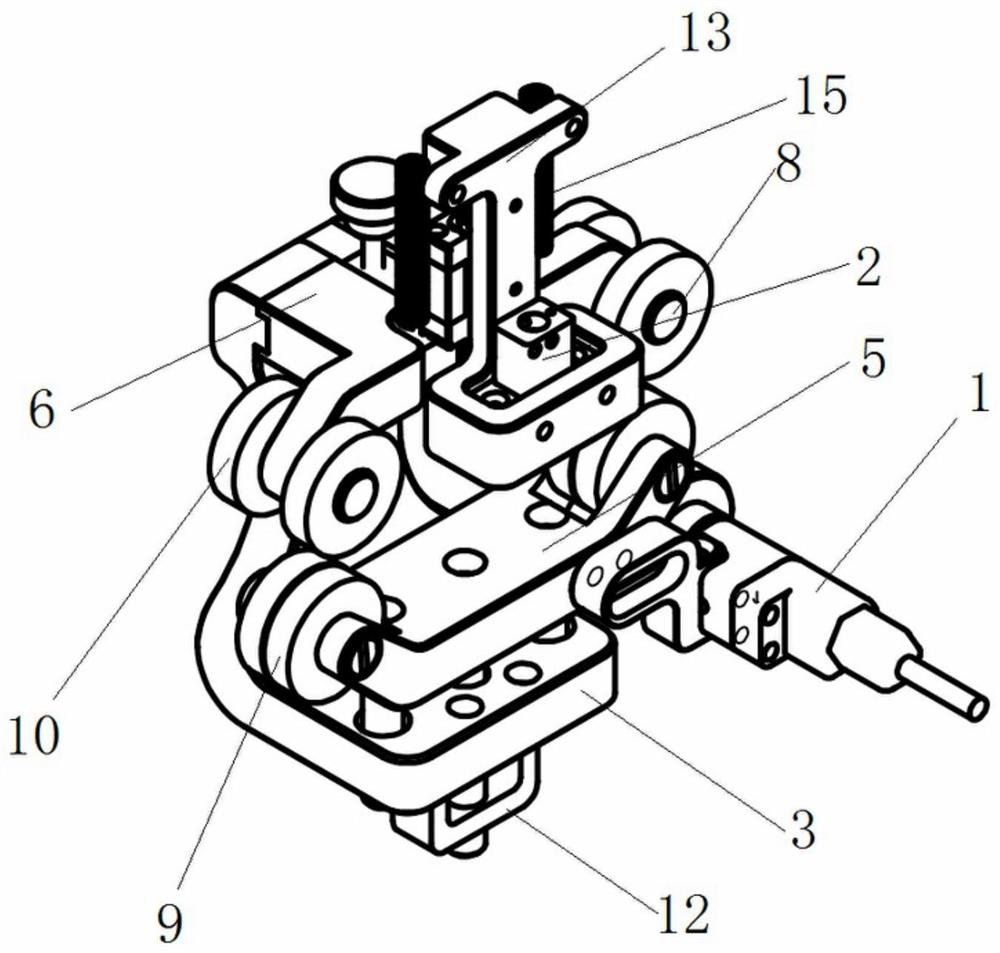

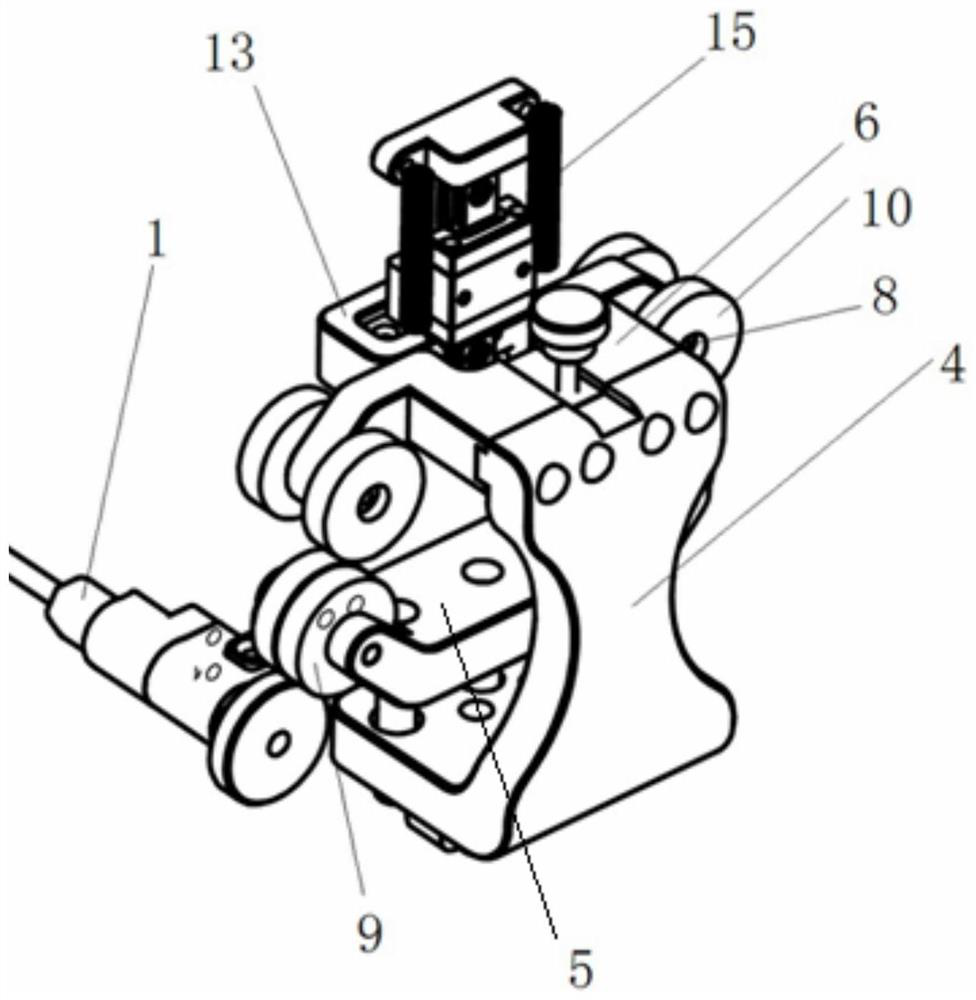

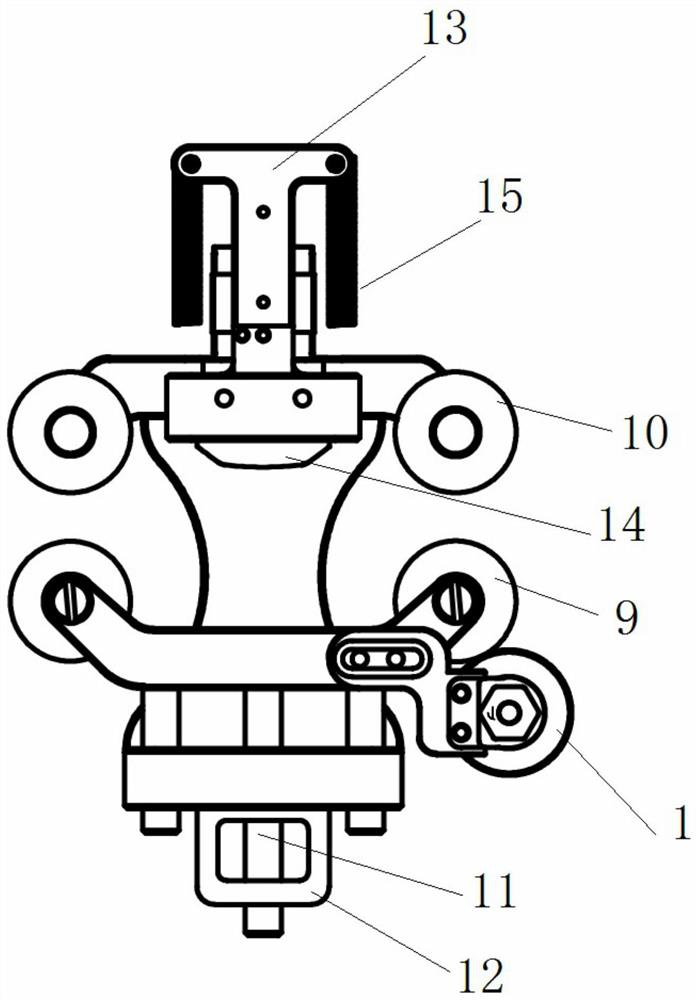

[0029] according to Figure 1-5 As shown, an air duct electron beam weld seam ultrasonic detection probe includes an encoder 1, a probe 2 and a tooling 3;

[0030] The encoder 1 and the probe 2 are fixed on the tooling 3;

[0031] The tooling includes a hand-held scanning frame 4, an upper bracket 5 and a lower bracket 6, and the hand-held scanning frame 4 is in the shape of an L frame;

[0032] The upper bracket 5 and the lower bracket 6 are in a figure-eight shape, the two ends of the upper bracket 5 are provided with notches 7 for installing rubber wheels, and the two ends of the lower frame 6 are provided with installation shafts 8, and there is an installation groove in the middle;

[0033] Both ends of the upper bracket 5 are provided with two lower rubber wheels 9 inside and outside, and the two lower rubber wheels 9 are closely placed, and the two lower rubber wheels 9 are inserted into the mounting holes of the upper bracket 5 through the shaft. The lower rubber whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com