High-voltage dry reed electric contact device

An electrical contact and reed technology, which is applied in the field of testing equipment, can solve the problem that the magnet and the reed switch have a large attraction and disconnection force, the large magnetic magnet is short board, and the pressure gauge movement cannot drive the movable conductive needle to open and close, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

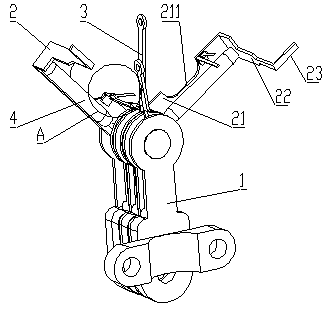

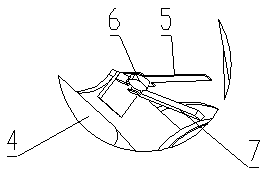

[0024] see figure 1 and figure 2 , the present invention provides a high-voltage dry reed electrical contact device, including a bracket 1, a shaft rod is arranged horizontally on the upper part of the bracket 1, and the shaft rod is rotated to connect two setting needles 2 and one end of the movable needle 3 for setting the upper and lower limits of the pressure gauge , the reed switch 4 is fixedly arranged on the setting pin 2, the setting pin 2 is a bent strip-shaped plate body, including the bottom plate 21 at the bottom, the bottom end of the bottom plate 21 is connected to the shaft in rotation, and the top of the bottom plate 21 is sequentially The middle plate 22 and the upper plate 23 are arranged, the plates of the middle plate 22 and the bottom plate 21 are vertical, the plates of the upper plate 23 and the bottom plate 21 are parallel, and the dry reed switch 4 is fixedly arranged on the plate of the bottom plate 21, and the dry reed The axis of the tube 4 is par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com