Static strength test mounting tool for suspension seat of rail car

A suspension seat and static strength technology, which is applied in the field of auxiliary tooling for physical measurement of railway vehicle testing, can solve the problems that the opening size of the tooling cannot be adjusted adaptively, the static strength testing tooling has limited measuring points, and the repeated utilization rate is low, etc. The supporting strength is stable and reliable, the versatility is excellent, and the adjustment is dexterous and convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

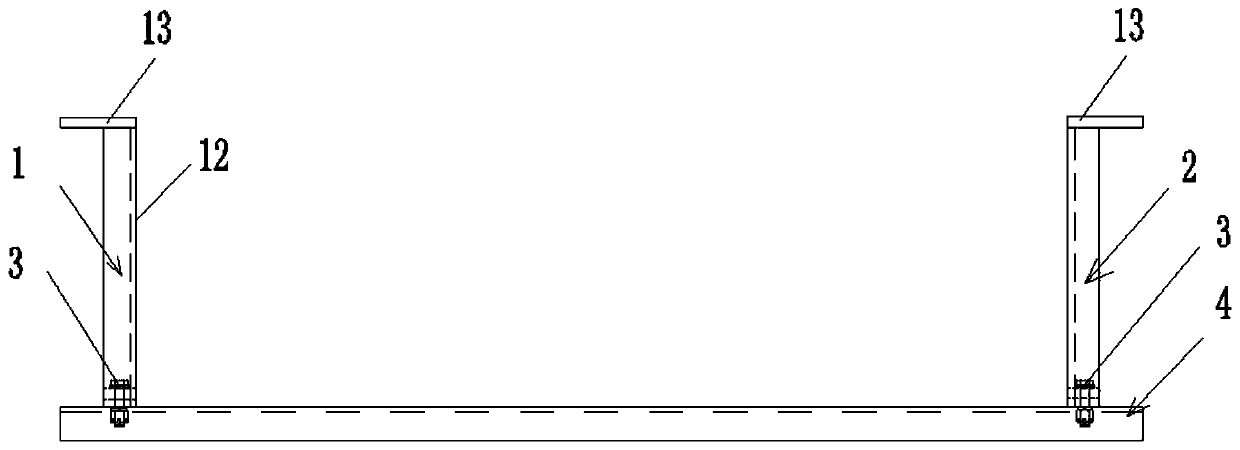

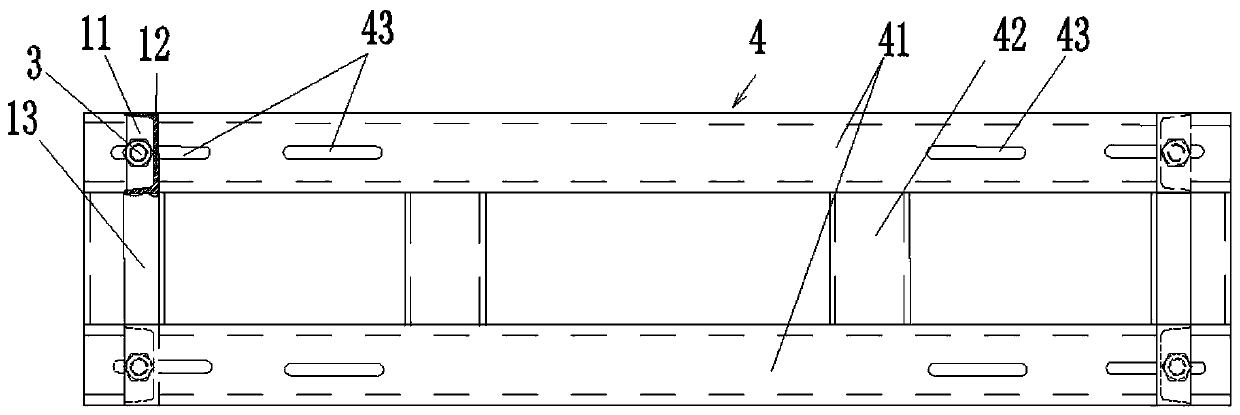

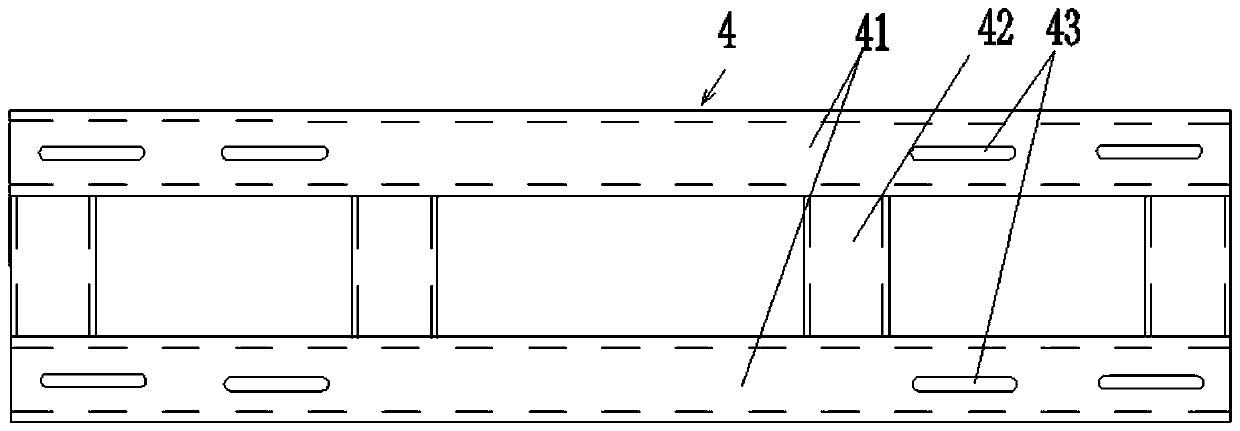

[0020] Attached below Figure 1-7 Specific examples of the present invention are described. It should be understood that the embodiments described below are only illustrative rather than specific limitations on the present invention.

[0021] The following examples facilitate a better understanding of the present invention, but do not limit the present invention. The experimental methods in the following examples are conventional methods unless otherwise specified. The test materials used in the following examples are commercially available unless otherwise specified. The pneumatic or hydraulic mechanism related to the tooling omitted in the following embodiments, as well as the sensor connected to the pneumatic or hydraulic mechanism and the realization of the sensor-related finite element analysis system electrical, circuit and other control circuits are all conventional tests under the prior art and control methods.

[0022] In the present invention, unless stated other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com