A method for directional docking of cylindrical single crystals

A cylindrical, single crystal technology, applied in chemical instruments and methods, crystal growth, after treatment, etc., can solve problems such as cumbersome process, unstable axial crystal orientation, azimuth angle, and damage to sample integrity, so as to improve work efficiency , the effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

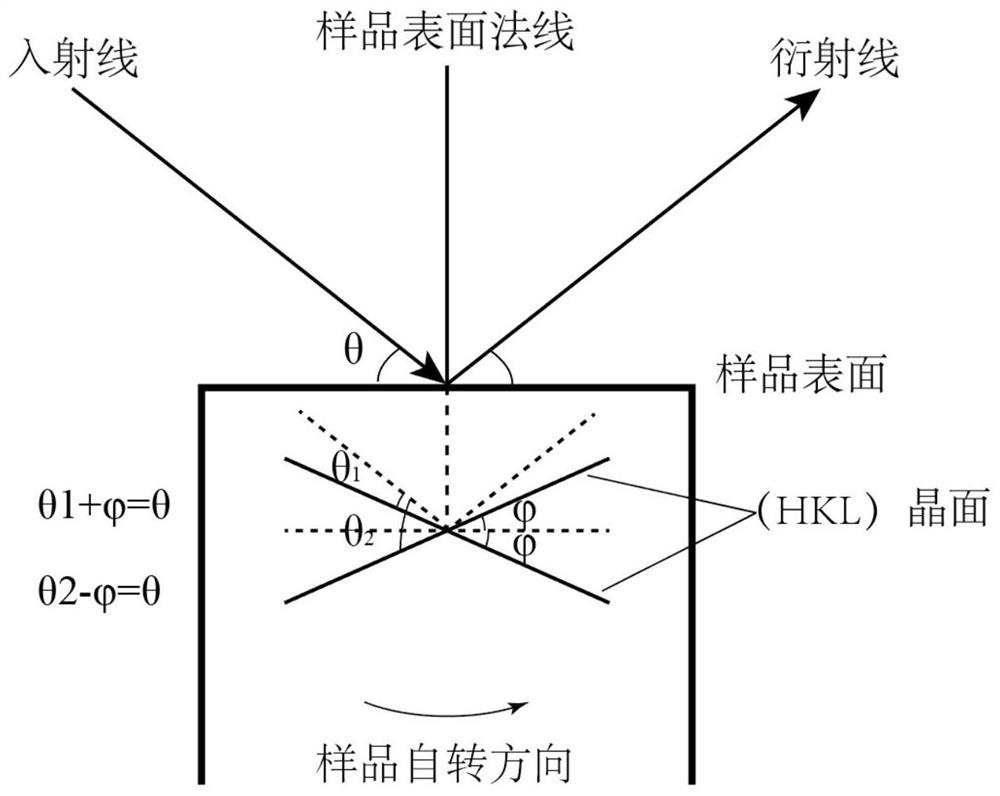

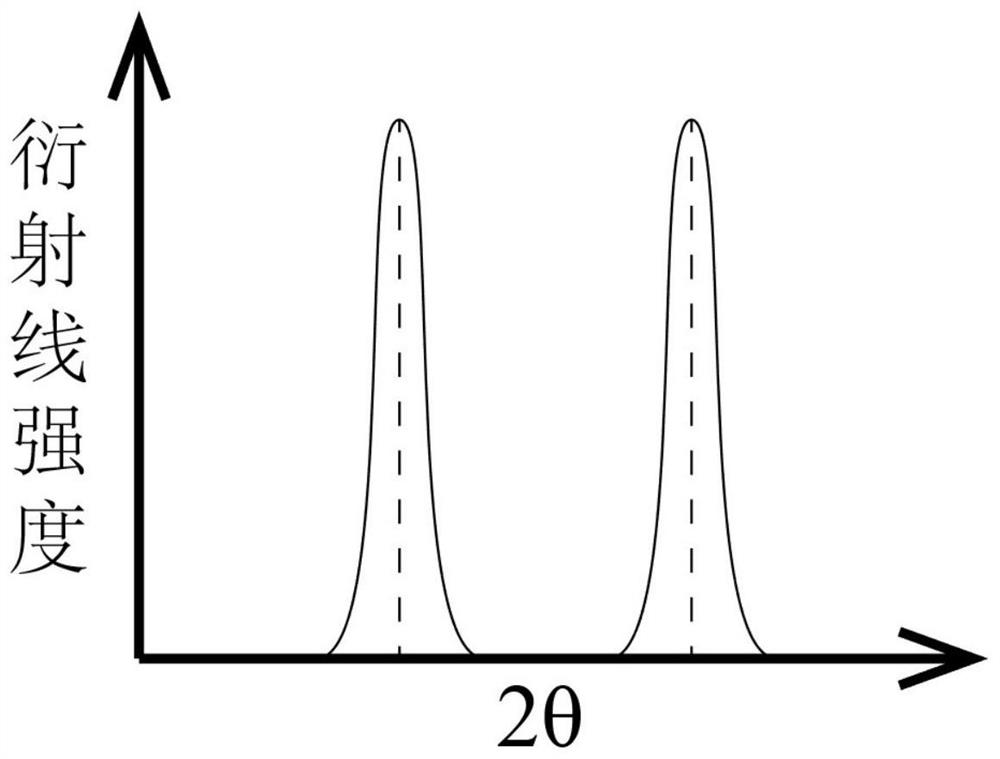

Method used

Image

Examples

Embodiment

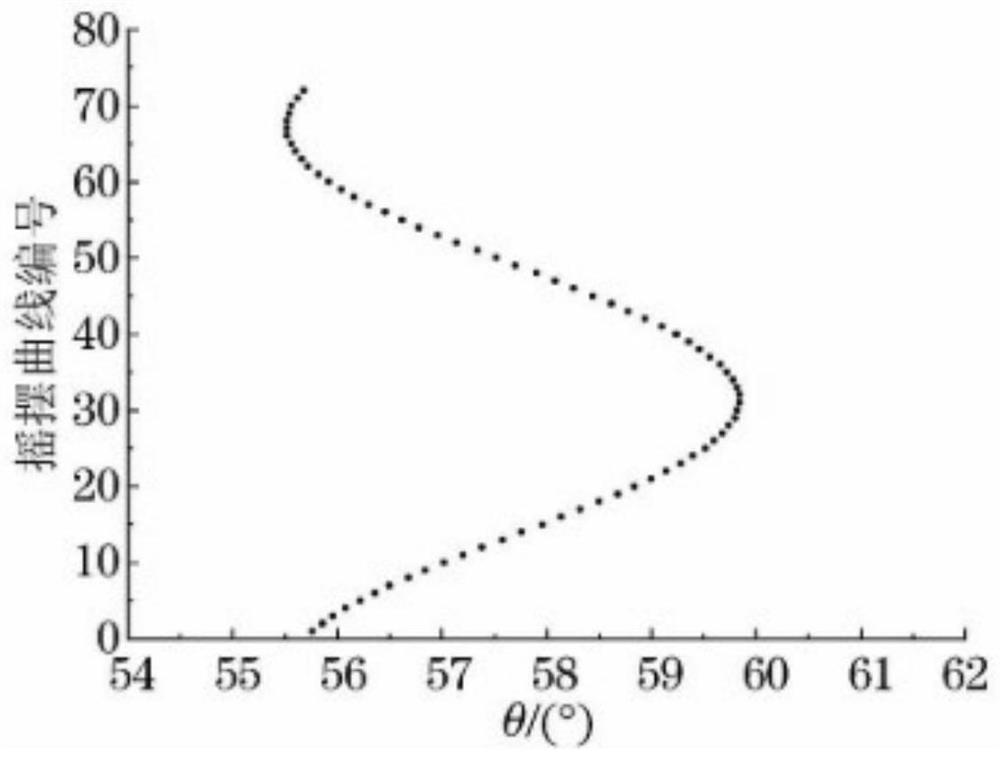

[0076] The raw material used in the orientation experiment is a Mo alloy single crystal rod (Mo-3Nb) with a Nb content of 3% prepared by the electron beam suspension area melting furnace of the Northwest Nonferrous Metals Research Institute, with an outer diameter of 25 mm and an axial crystal orientation of . The complete process of single crystal directional docking is introduced in detail as follows:

[0077] 1) Excel pre-enters the calculation formulas of α and β angles, and [100][010][001] is preset in the single crystal diffractometer as the reference crystal orientation;

[0078] 2) Decontamination and polishing treatment on the surface of the single wafer rod;

[0079] 3) if Figure 8 As shown, fix the protractor on the single crystal A, place the sample and gently lean on the positioning probe, rotate the sample until the pointer of the protractor coincides with the 0 degree of the disc, fix the sample, and lift the sample stage to ensure that the X-rays ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com