Battery conveying steering mechanism

A steering mechanism and battery technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of unreliable work, low efficiency, large production workshop area, etc., and achieve reliable work process, improved level, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

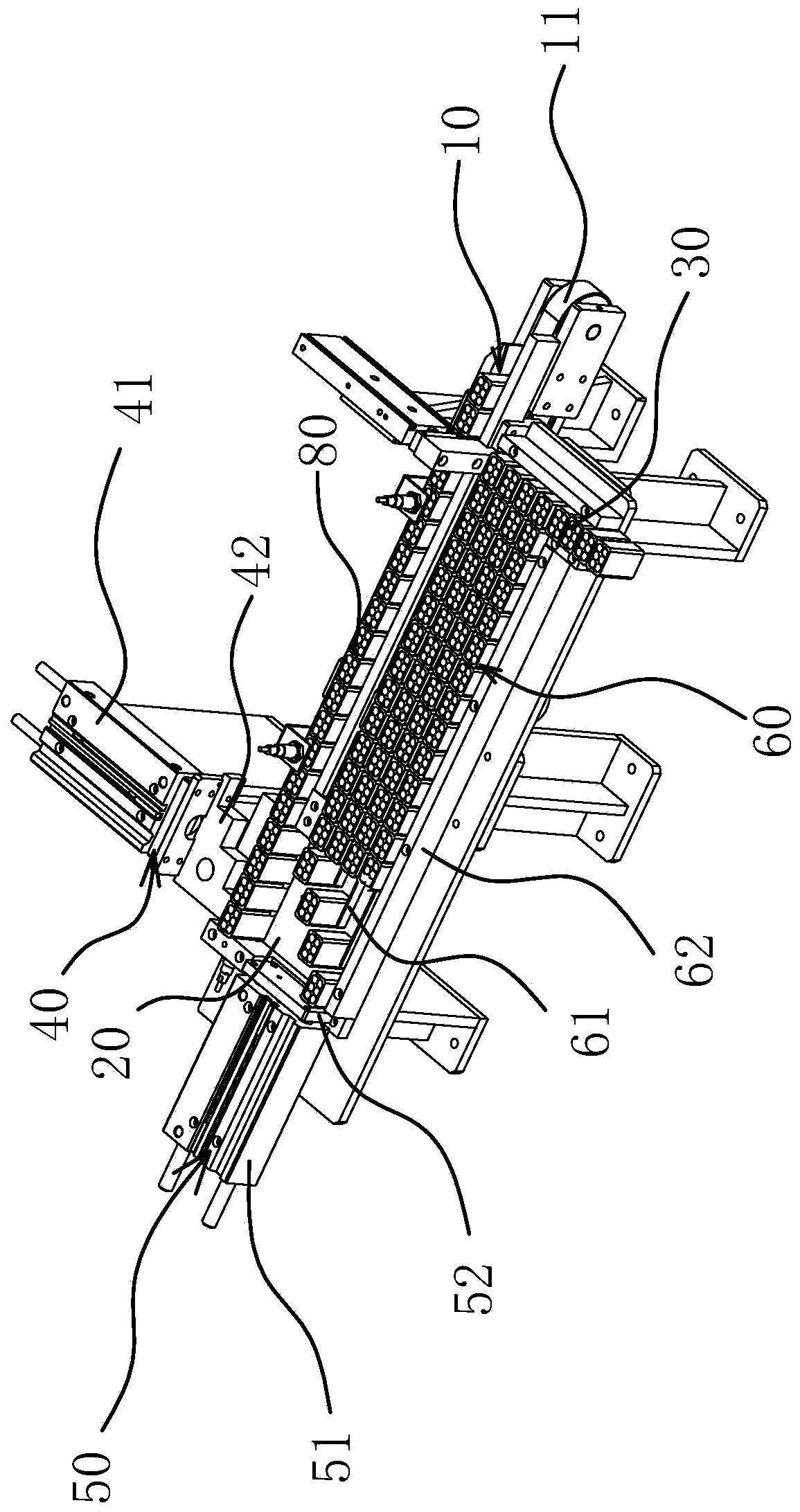

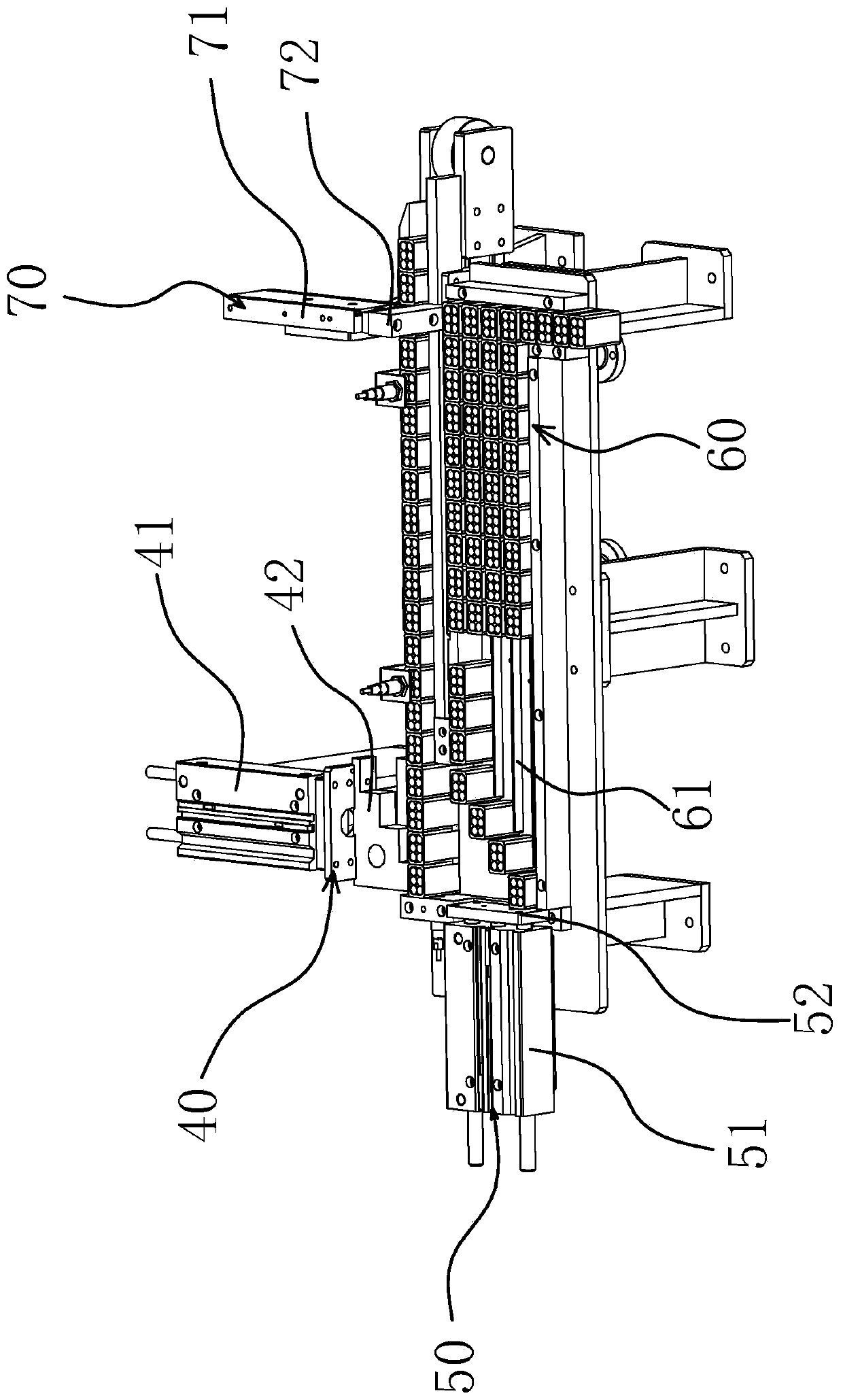

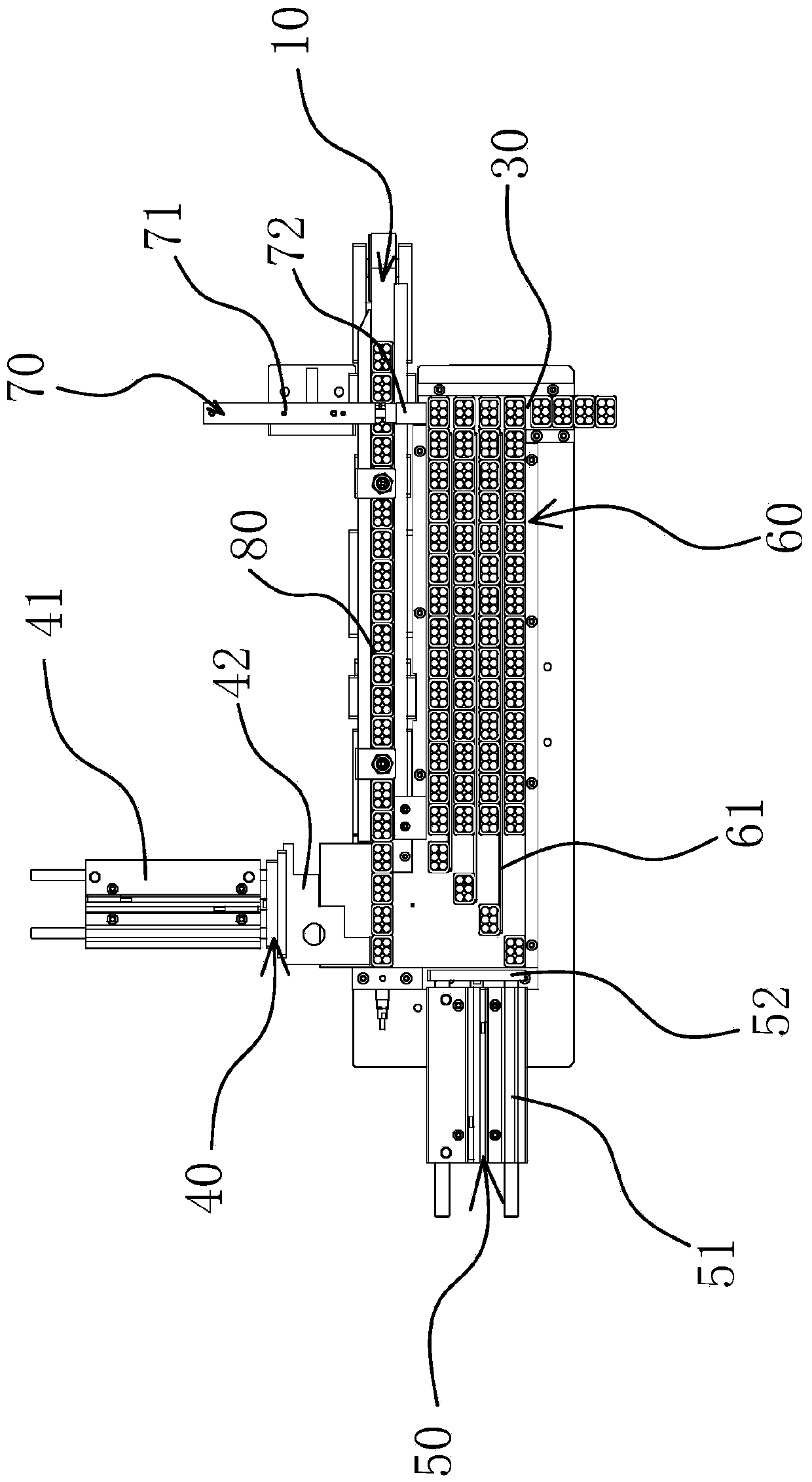

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0023] The invention protects a battery conveying steering mechanism, which can be used for batteries, especially 9V batteries, battery steel shells or any square parts that need to be automatically turned on the production line, and it is convenient to enter the next one after turning. The production work is carried out, and the whole steering process has simple steps and high work efficiency, and is suitable for a production environment with high automation requirements.

[0024] Combine below Figure 1 to Figure 4 The technical solution provided by the present invention is described in more detail.

[0025] Such as figure 1 As shown, the battery delivery steering mechanism includes:

[0026] The input channel 10 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com