Geomembrane production system and technology

A production system and geomembrane technology, applied in the direction of flat products, household appliances, other household appliances, etc., can solve the problems of time-consuming and laborious manual unloading, high labor intensity, and heavy geomembrane weight, etc., to reduce labor intensity, improve The effect of production quality and labor intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

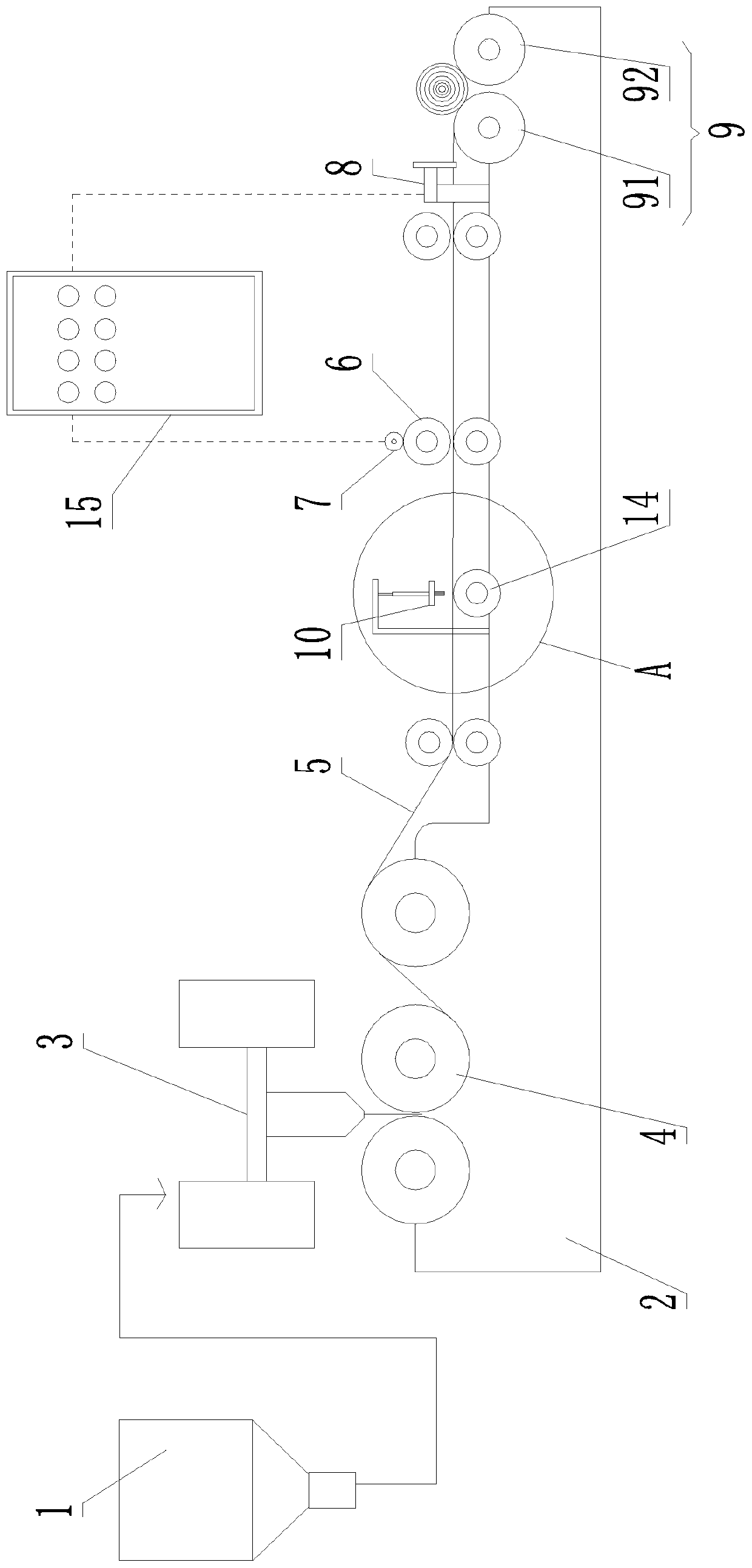

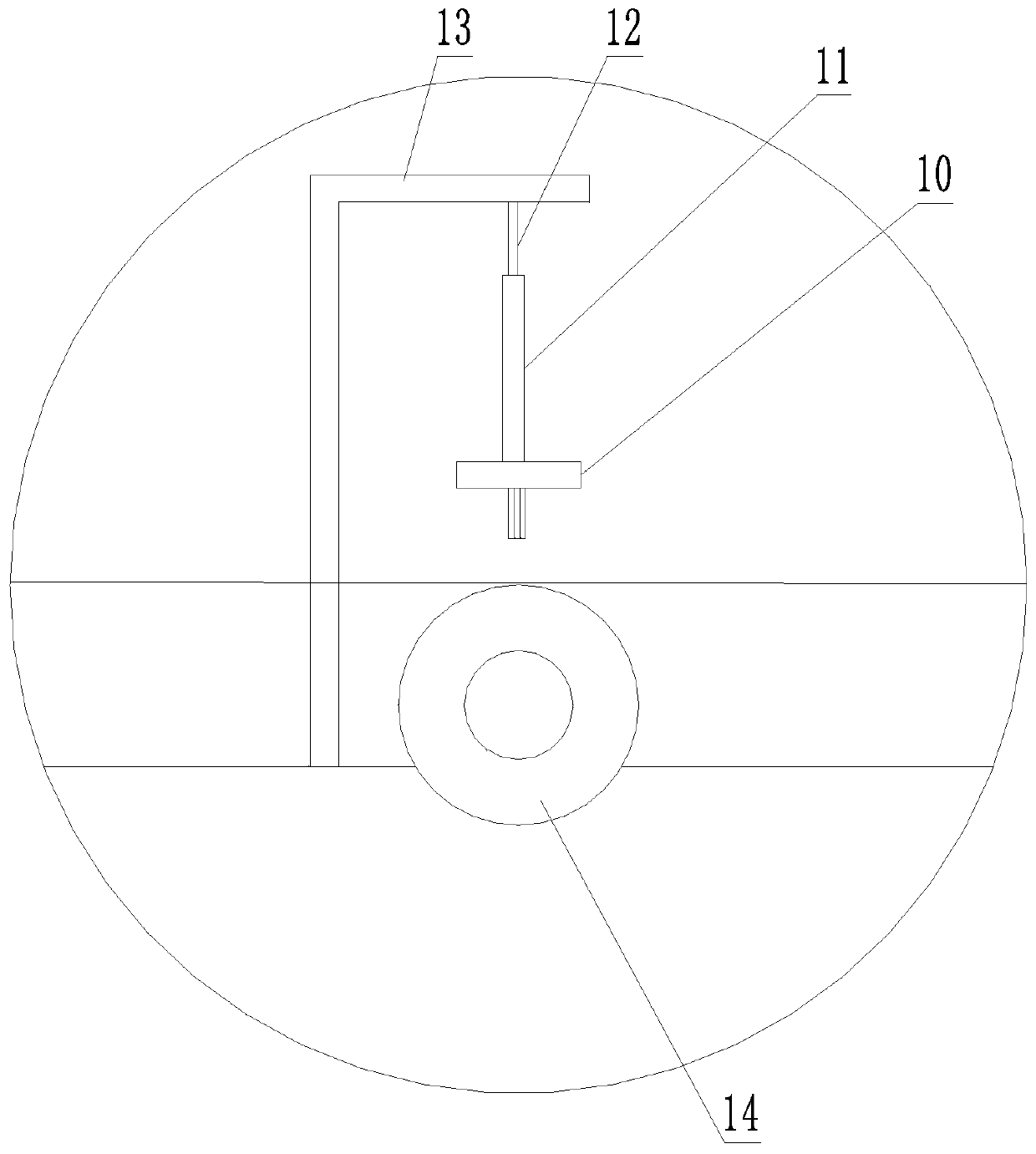

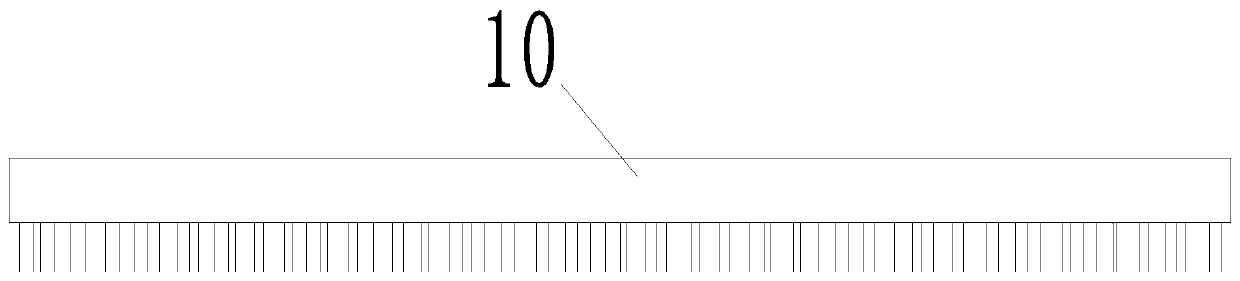

[0046] Such as Figure 1-4 As shown, a kind of geomembrane production system that the present embodiment proposes comprises feeding mechanism 1 and frame 2, and frame 2 is provided with screw extruder 3, traction mechanism and is used for conveying geomembrane 5 and has conductive function. The transmission roller 14.

[0047] Wherein, the feeding mechanism 1 is used to transport raw materials to the screw extruder 3 , and the feeding mechanism 1 includes a stirring tank 101 , and a supporting leg 112 is welded on the outer wall of the stirring tank 101 .

[0048] A hopper 106 is arranged below the stirring tank 101, and the hopper 106 is arranged in a conical shape. The big end of the hopper 106 is on the top and is an open end, and the small end of the hopper 106 is on the bottom and is a closed end.

[0049] The bottom of the mixing tank 101 is also conical, and the center of the bottom of the mixing tank 101 is provided with a feeding port 103, and the stirring tank 101 i...

Embodiment 2

[0064] Such as Figure 5-7 As shown, a kind of geomembrane production system proposed in this embodiment, other mechanisms are the same as Embodiment 1, the difference is that, in this embodiment, in order to facilitate unloading, there are two ends of the first rotating roller 91 for The unloading mechanism for auxiliary unloading, the unloading mechanism includes a support frame 95, the number of support frames 95 at each end is provided with 2, the support frame 95 is connected with the frame 2, and the support frame 95 is provided with a chute 98; The two ends of the rotating roller 91 are connected with bearings 93, and the outer wall of the bearing 93 is connected with a slide block 94 that can go up and down along the chute 98, and the slide block 94 is compatible with the chute 98; the upper end of the bearing 93 is connected with a cylinder that drives the bearing 93 to go up and down 97, the cylinder 97 is fixed on the top plate 96; the top plate 96 is fixedly connec...

Embodiment 3

[0066] continue to refer figure 1 , a kind of geomembrane production system that present embodiment proposes, and other mechanism is identical with embodiment 2, difference is, in this embodiment, frame 2 is also provided with the automatic cutting device 8 that is used for cutting geomembrane 5 transversely , the automatic cutting device 8 is arranged on the front of the winding machine 9; there is also a meter meter, 7, and the meter meter 7 can be selected from a roller-type meter meter, which is arranged on the top of the traction roller 6, and the meter meter is driven by the traction roller 6. The roller rotation of meter device 7 realizes metering.

[0067] In order to improve the intelligence of the whole system, the automatic cutting device 8, the meter counter 7 and the cylinder 97 are all connected with a control system.

[0068] The present invention also proposes a geomembrane production process, comprising the following steps:

[0069] S1: Ingredients mixing

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com