Rotary automatic lifting handrail

An automatic lifting and rotating lifting technology, which is applied to other seating furniture, chairs, stools, etc., can solve the problems of complex lifting and adjusting structure of armrests, high production and maintenance costs, and inaccurate positioning, so as to achieve simple structure and prolong service life , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

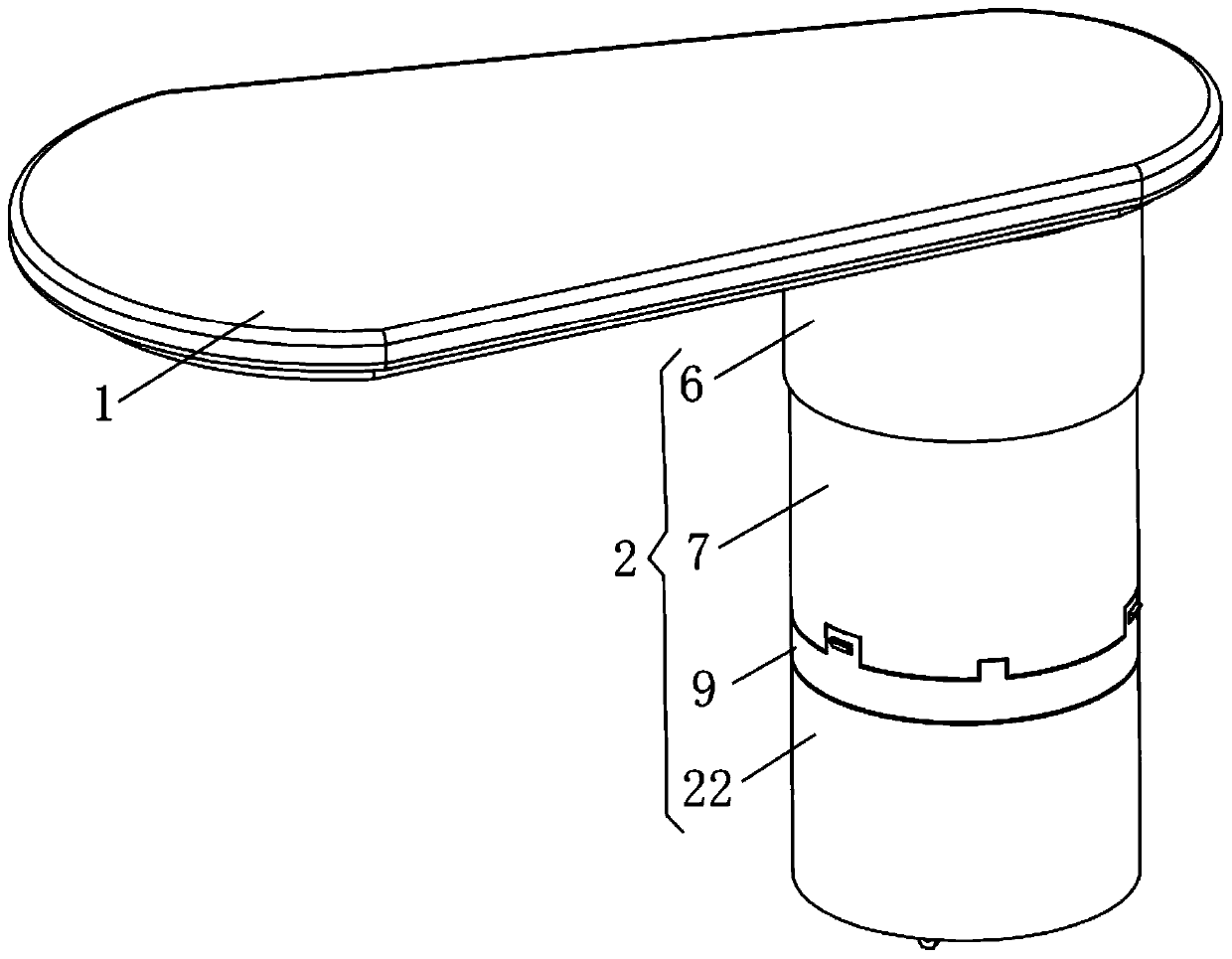

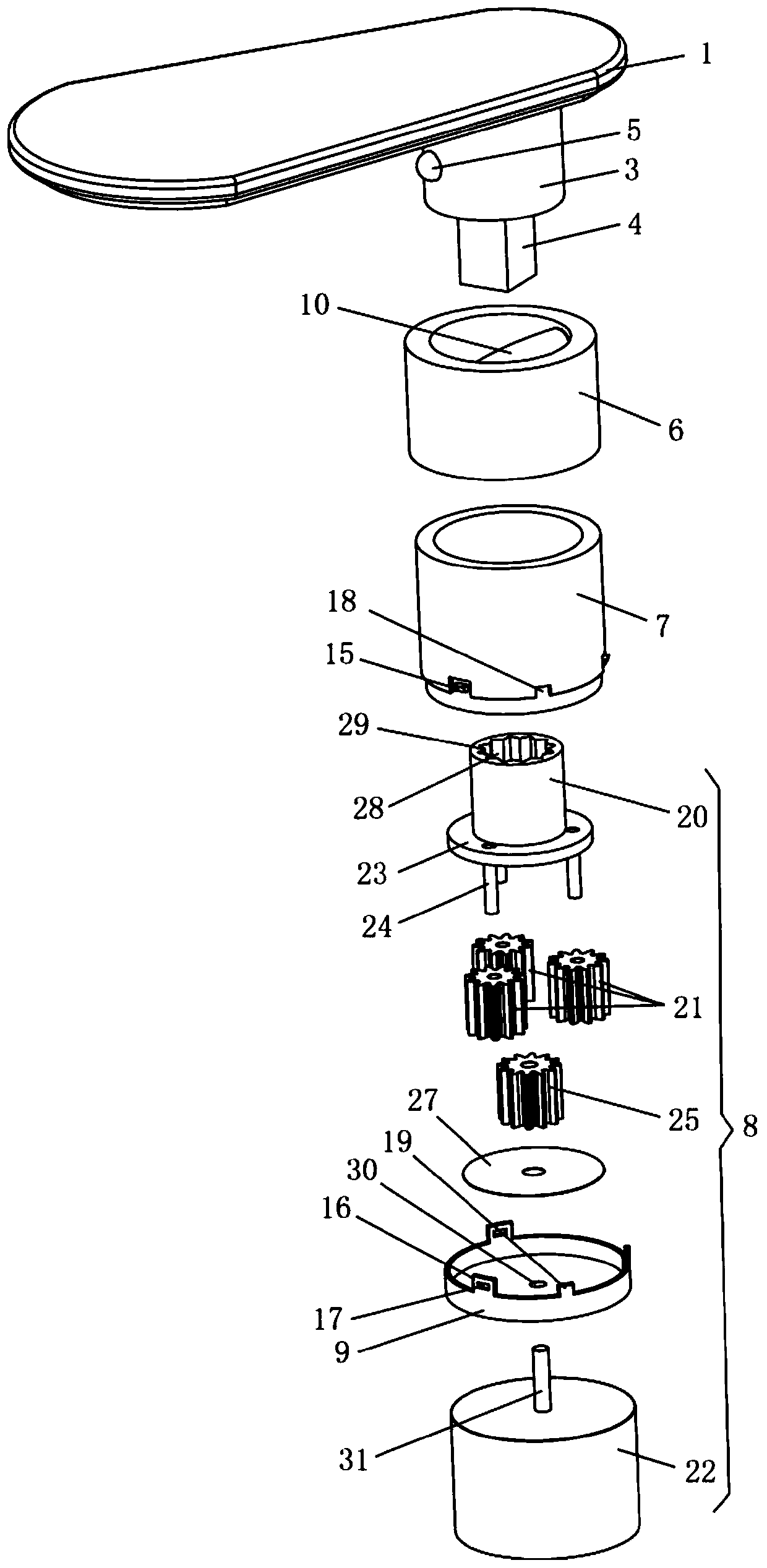

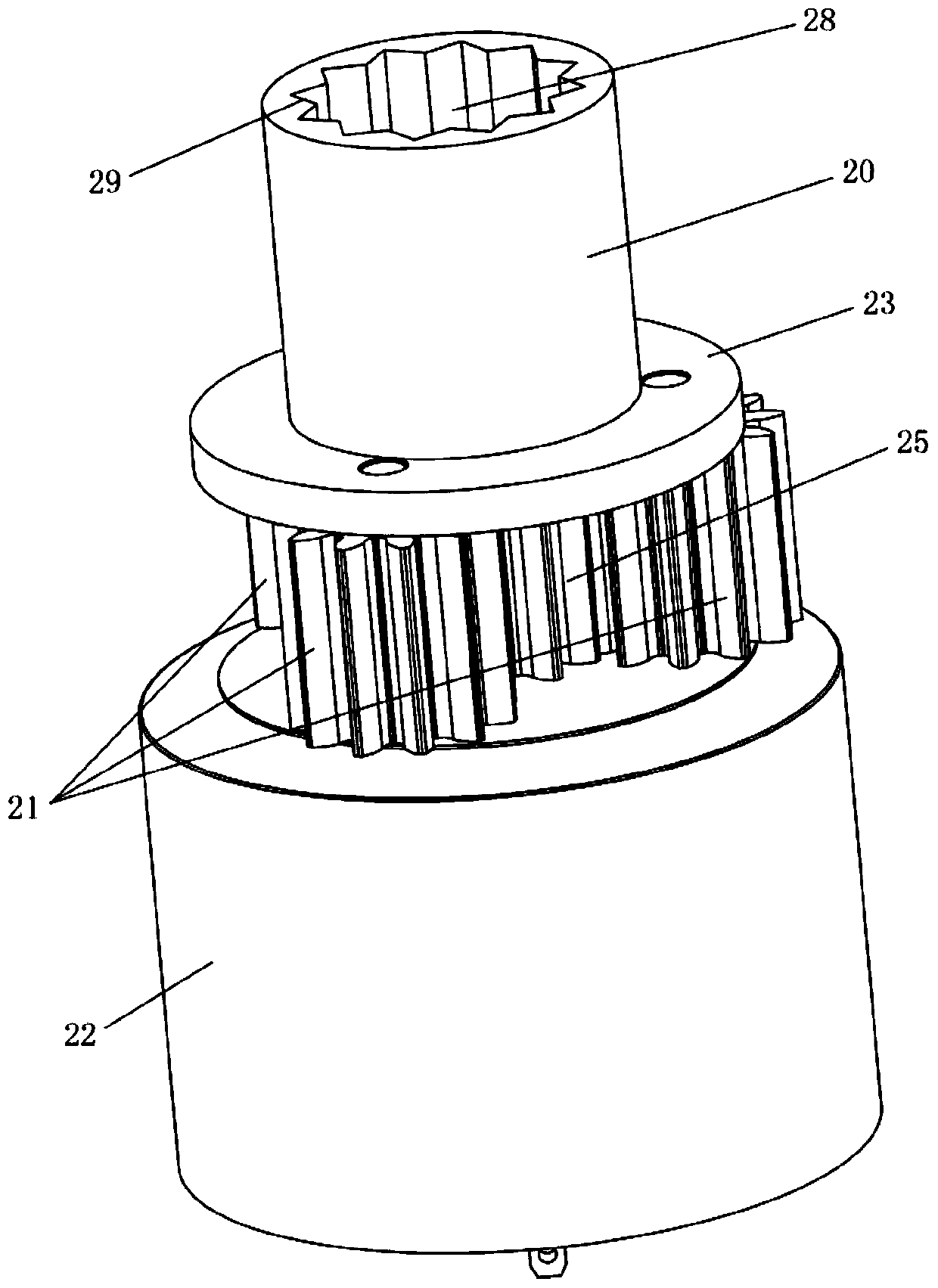

[0026] like Figure 1-7 As shown, a rotary automatic lifting handrail includes a hand rest 1 and a rotating lifting device 2, the bottom of the hand rest 1 is provided with an engaging block 3, and the bottom of the engaging block 3 is provided with a transmission block 4. The outer wall of the block 3 is provided with at least one outwardly protruding steel ball 5. The rotary lifting device 2 includes an orbital ring 6, an inner ring gear 7, a transmission mechanism 8 and a fixed seat 9. The orbital ring 6 is installed on On the inner ring gear 7, the transmission mechanism 8 is connected to the inner ring gear 7, the fixed seat 9 is fixedly mounted on the inner ring gear 7, and the track ring 6 is provided with a The ball 5 cooperates with the sliding guide rail 10, the first and last ends of the sliding guide rail 10 are distributed on the inner side wall of the track ring 6, and the hand rest 1 is rotatably mounted on the connecting block 3 In the track ring 6, the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com