Compressor machine

A compressor and machine technology, applied in the field of compressor machines, can solve problems affecting the thermal dynamic efficiency of compressor machines, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

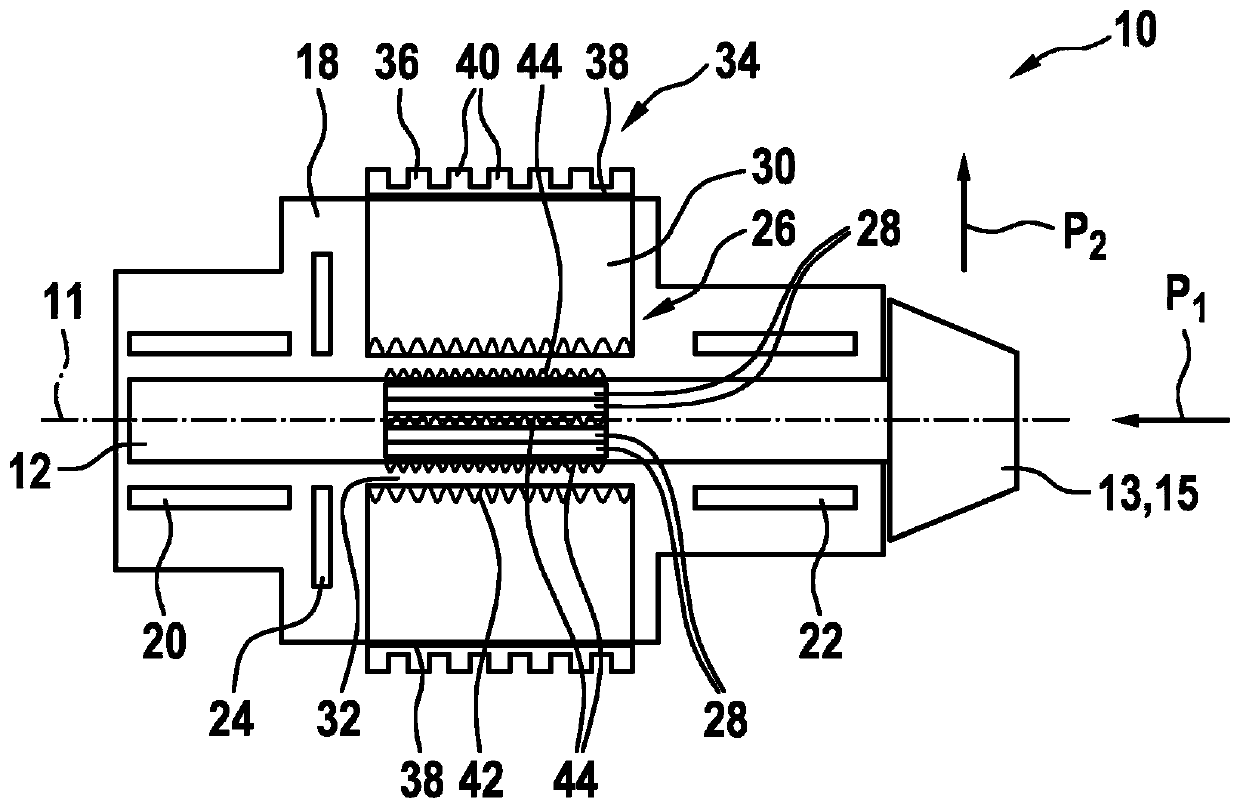

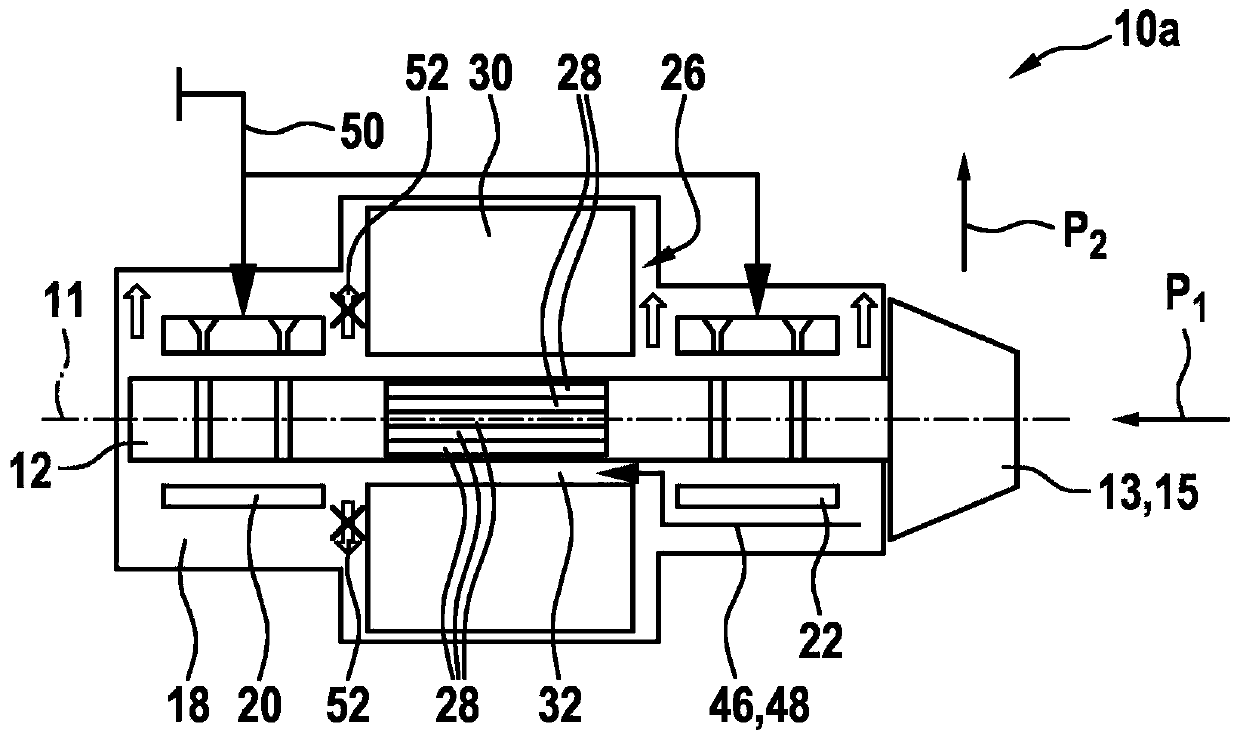

[0019] figure 1 A first compressor machine 10 is shown very schematically. The compressor machine 10 is used for compressing gas and for this purpose has a shaft 12 mounted rotatably about a longitudinal axis 11 , which is connected at one end in a rotationally fixed manner to a compressor stage 15 with an impeller 13 . The compressor stage 15 or impeller 13 is configured as a flow device to increase the gas supplied to or sucked by the impeller 13 from a first pressure p1 to a second pressure p2, which is greater than the first pressure p2. pressure p1. The compressor machine 10 or the compressor arrangement also has a housing 18 shown only in area, in which the shaft 12 is arranged at least in area. The housing 18 is also used to arrange two radial bearings 20, 22 and an axial bearing 24, wherein the bearings are configured as dynamic pressure air bearings or static pressure air bearings, that is, the bearings use gas or air as the shaft 12 and the corresponding Work in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com