F-P cavity type high-temperature large-strain optical fiber sensor

An optical fiber sensor, F-P technology, applied in the field of sensors, can solve problems such as low measurement accuracy, range influence, and low precision, and achieve the effects of avoiding range limitation, reducing transmission resistance, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

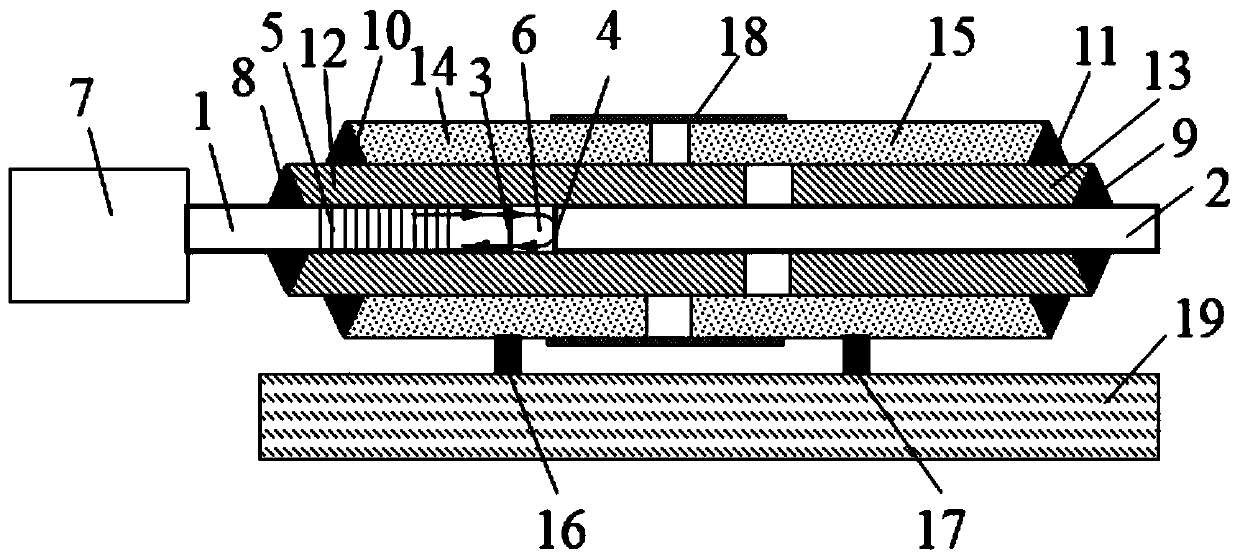

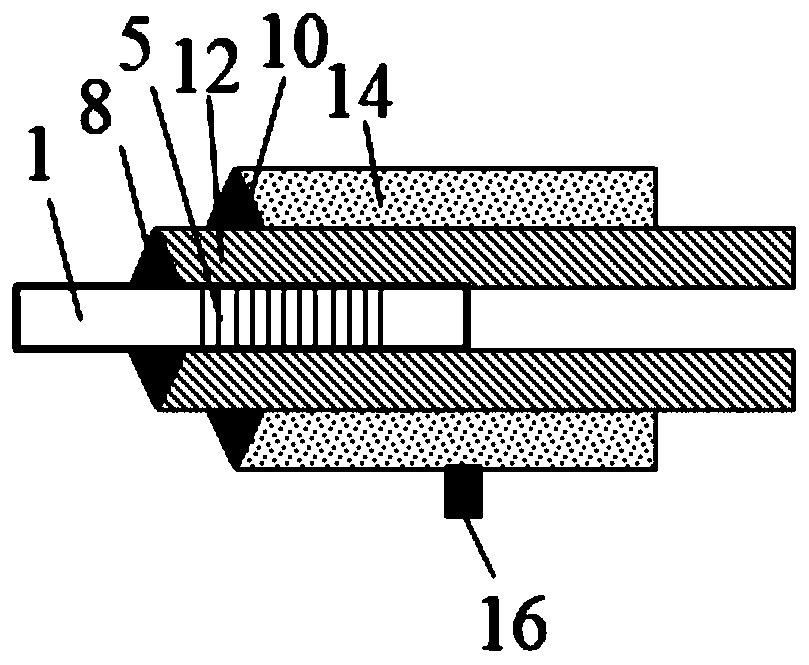

[0031] Embodiment 1: High-temperature strain sensor using Fabry-Perot (F-P) interference when using the end face of an optical fiber as a mirror

[0032] An F-P cavity-type high-temperature and large-strain optical fiber sensor, including a transmission optical fiber 1, an optical fiber 2, an inner sleeve, an outer sleeve, a clamp, a connecting key, and a sealing structure 18;

[0033] One end of the transmission fiber 1 is connected to the spectrometer 7, and the other end is used as the first reflective surface 3 and the end is opposite to the optical fiber 2 as the second reflective surface 4, and the cavity between the two is a Fabry-Perot interference cavity 6. A temperature sensor 5 is written on the transmission optical fiber 1, and the temperature sensor 5 is located in the first inner casing 12;

[0034] The inner sleeve includes a first inner sleeve 12 and a second inner sleeve 13, both of which are sleeved on the outside of the transmission optical fiber 1 and the o...

Embodiment 2

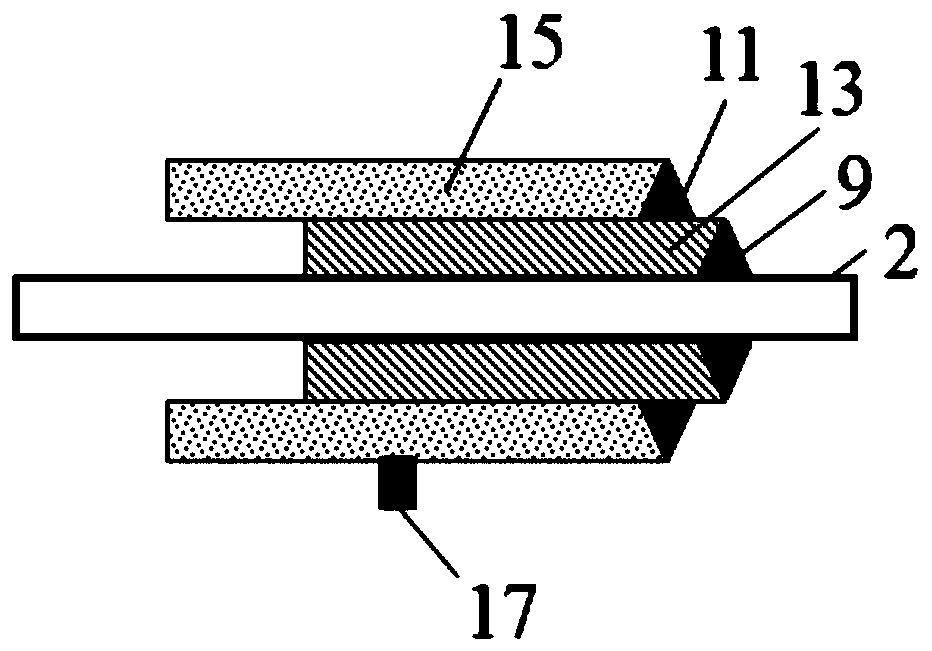

[0043] Embodiment 2: When a reflecting mirror is pasted, the F-P cavity type high-temperature and large-strain optical fiber sensor is a high-temperature strain sensor of Fabry-Perot (F-P) interference, and the high-temperature strain sensor includes a transmission optical fiber 1, a plane mirror 20, The first reflective surface 3 , the second reflective surface 4 , the first inner sleeve 12 , the first outer sleeve 14 , the second outer sleeve 15 , the first clamp 16 , the second clamp 17 and the sealing structure 18 . The material of each part is the same as that in Embodiment 1 when the end surface of the optical fiber 2 is used as the reflection surface.

[0044] As shown in Figure 2, when the second reflective surface 4 is a plane mirror instead of an optical fiber, only the first inner sleeve 12, the first outer sleeve 14 and the second outer sleeve 15 are needed, and the second inner sleeve is not needed 13. The transmission optical fiber 1 is inserted from the first in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com