Goods sorting equipment and its sorting off-line device

A technology of goods and equipment, which is applied in the field of goods sorting equipment and its sorting off-line device, which can solve problems such as goods damage, goods or conveying line collision, extrusion, equipment failure, etc., to improve reliability and safety , to avoid the effect of equipment failure or damage to goods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

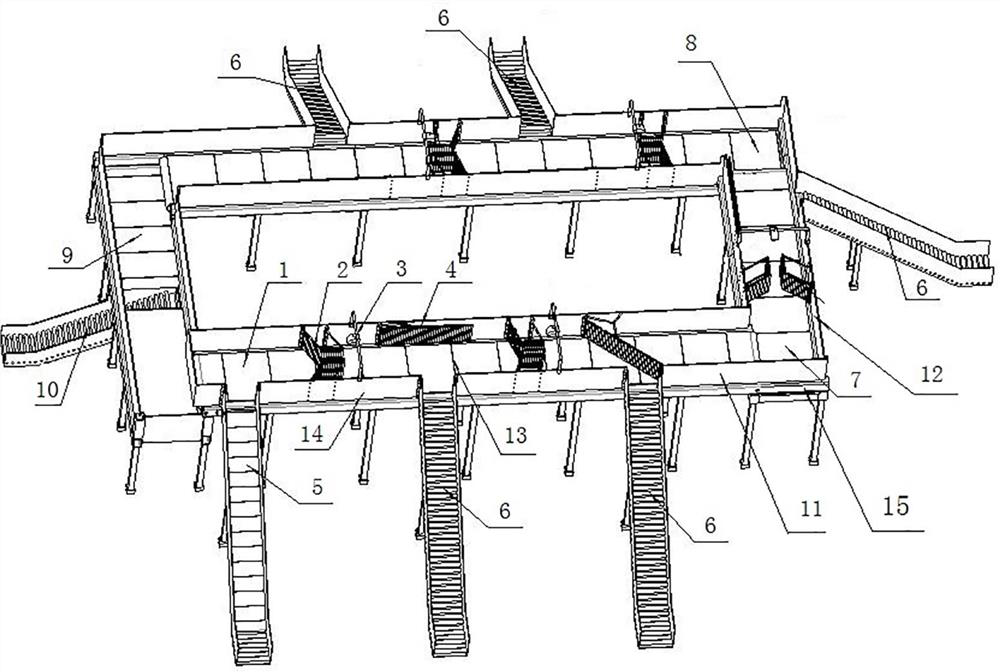

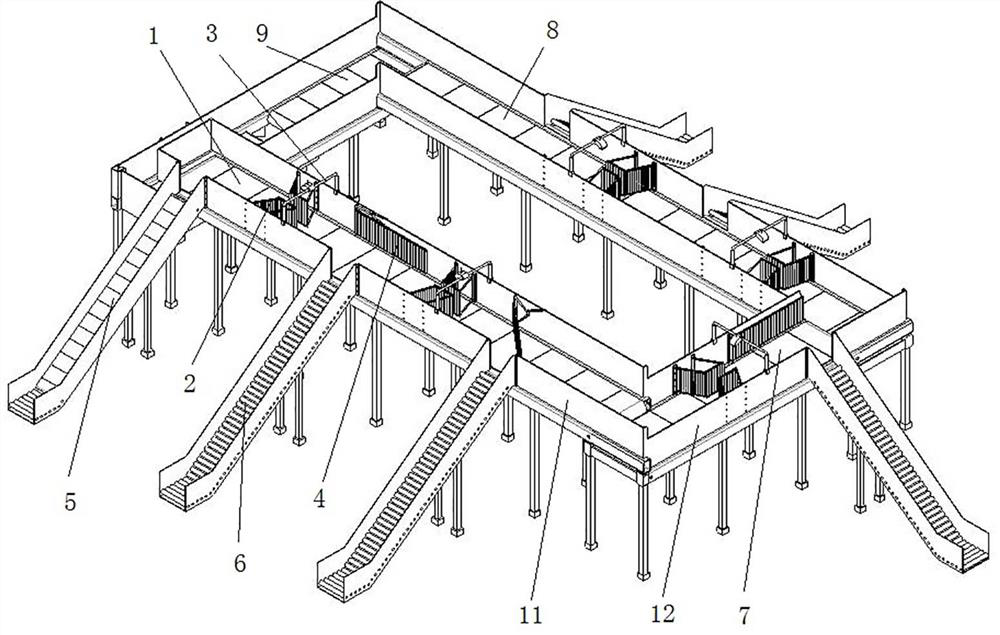

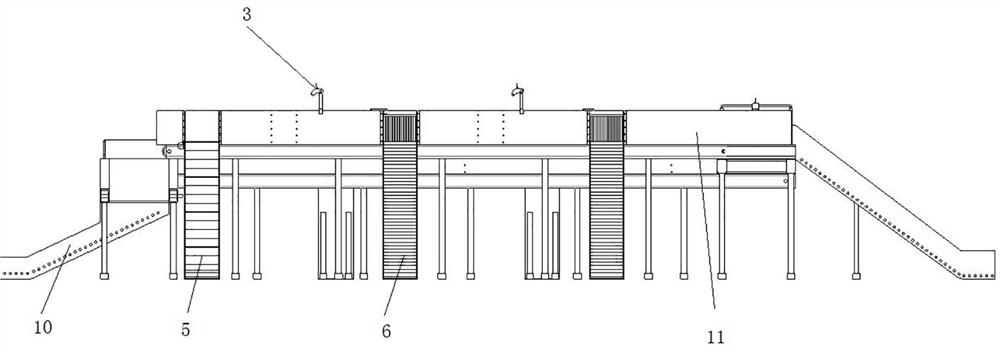

[0064] Such as Figure 1 to Figure 4 As shown, the cargo sorting equipment includes a conveyor belt 1, a conveyor belt 2 7, a conveyor belt 3 8 and a conveyor belt 9 9 extending in the horizontal direction, and each conveyor belt is ring-shaped. Wherein, the conveying direction of conveyer belt one 1 and conveyer belt three 8 is opposite, the conveying direction of conveyer belt two 7 and conveyer belt four 9 is opposite, the conveying direction of conveyer belt one 1 and conveyer belt two 7 is vertical in the horizontal direction, to be sorted The conveying directions of boxes on the box sorting and conveying device are conveyor belt one 1, conveyor belt two 7, conveyor belt three 8 and conveyor belt four 9, that is, conveyor belt two 7 is arranged downstream of conveyor belt one 1, and conveying Belt three 8 are arranged on conveyor belt two 7 downstreams, conveyor belt four 9 are arranged on conveyor belt three 8 downstreams, and conveyor belt four 9 are the final stage con...

specific Embodiment 2

[0080] Compared with the specific embodiment 1 of the goods sorting equipment in the present invention, the difference is only that: the driving device of the guiding arm in the above-mentioned embodiment 1 is an electric push rod 44, while the driving device of the guiding arm in this embodiment is a cylinder, and the driving device of the cylinder The connection position is the same as that of the electric push rod 44 in Embodiment 1.

specific Embodiment 3

[0082] Compared with the specific embodiment 1 of the goods sorting equipment in the present invention, the only difference is that in the above embodiment 1, the end of the electric push rod 44 away from the driver mounting seat is hinged on the first folding arm 42 and the second folding arm 43 The hinge shaft between them is arranged coaxially with the hinge shaft, and in this embodiment, the lead electric push rod 44 is hinged at the end of the first folding arm 42 close to the second bending arm. Of course, in other embodiments, the lead electric push rod 44 can also be hinged at the end of the second folding arm 43 close to the first bending arm, and can also be hinged at the end of the second folding arm 43 close to the first bending arm. When the middle part is hinged at the middle part of the bending wall, the initial angle between the electric push rod 44 and the corresponding folding arm can be appropriately increased to provide a larger driving force arm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com