Automatic piece arranging machine and piece arranging method thereof

A technology of automatic rowing and racking, which is applied in the field of material arrangement and its arrangement, can solve the problems of damaged wafer surface quality, high equipment cost, complex structure of automatic chip arrangement machine, etc., achieve low cost, compact chip arrangement, and improve the efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

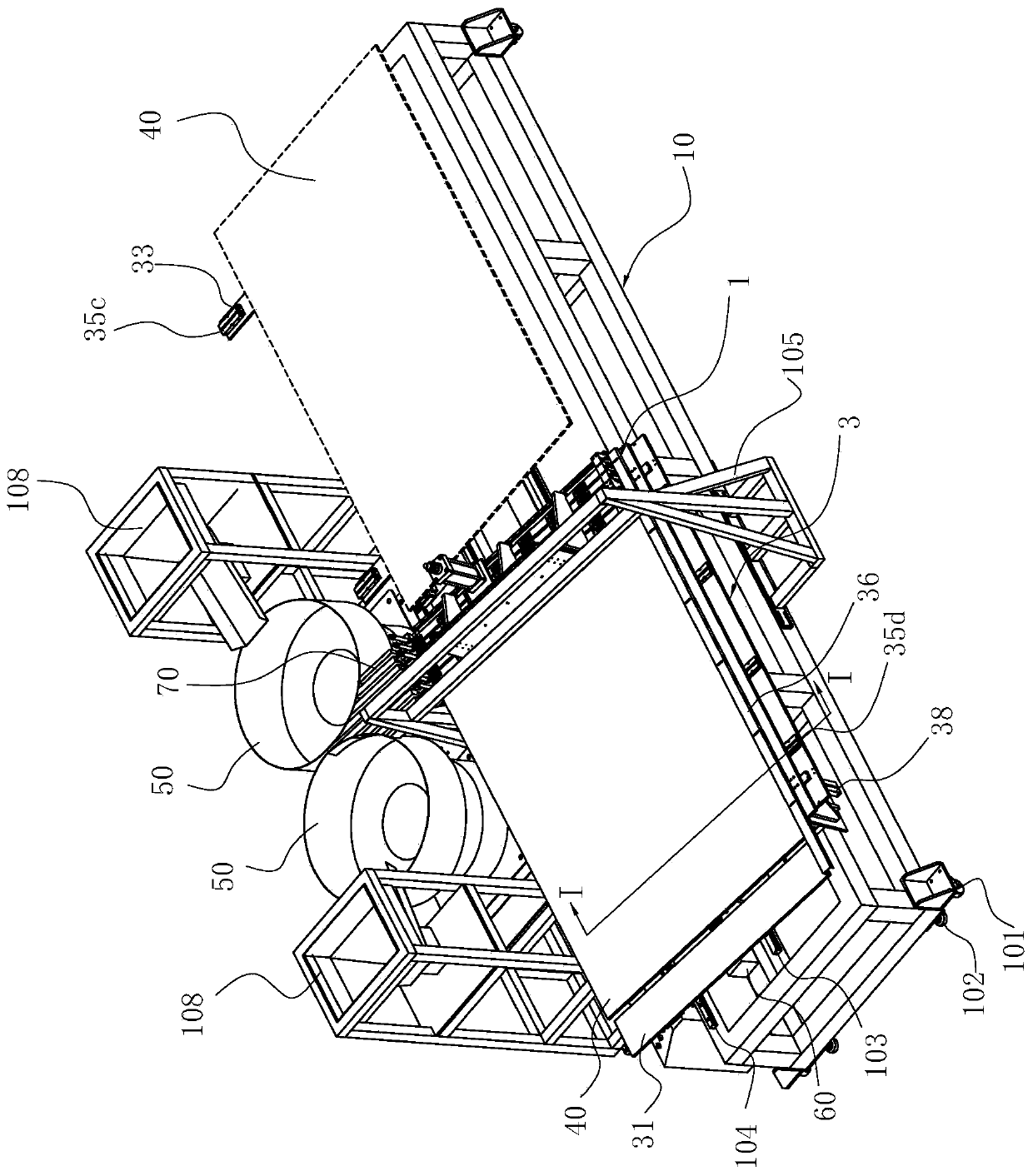

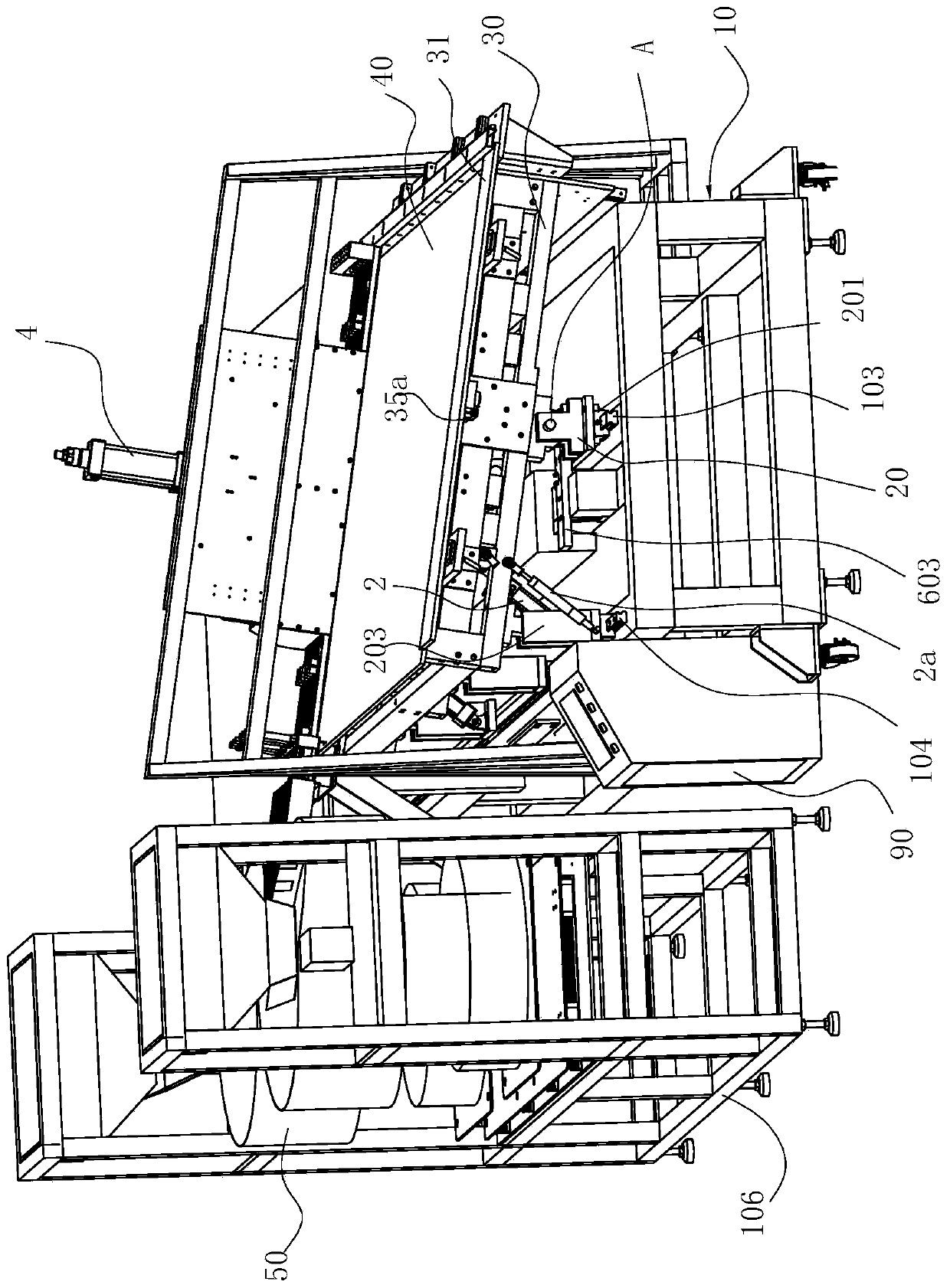

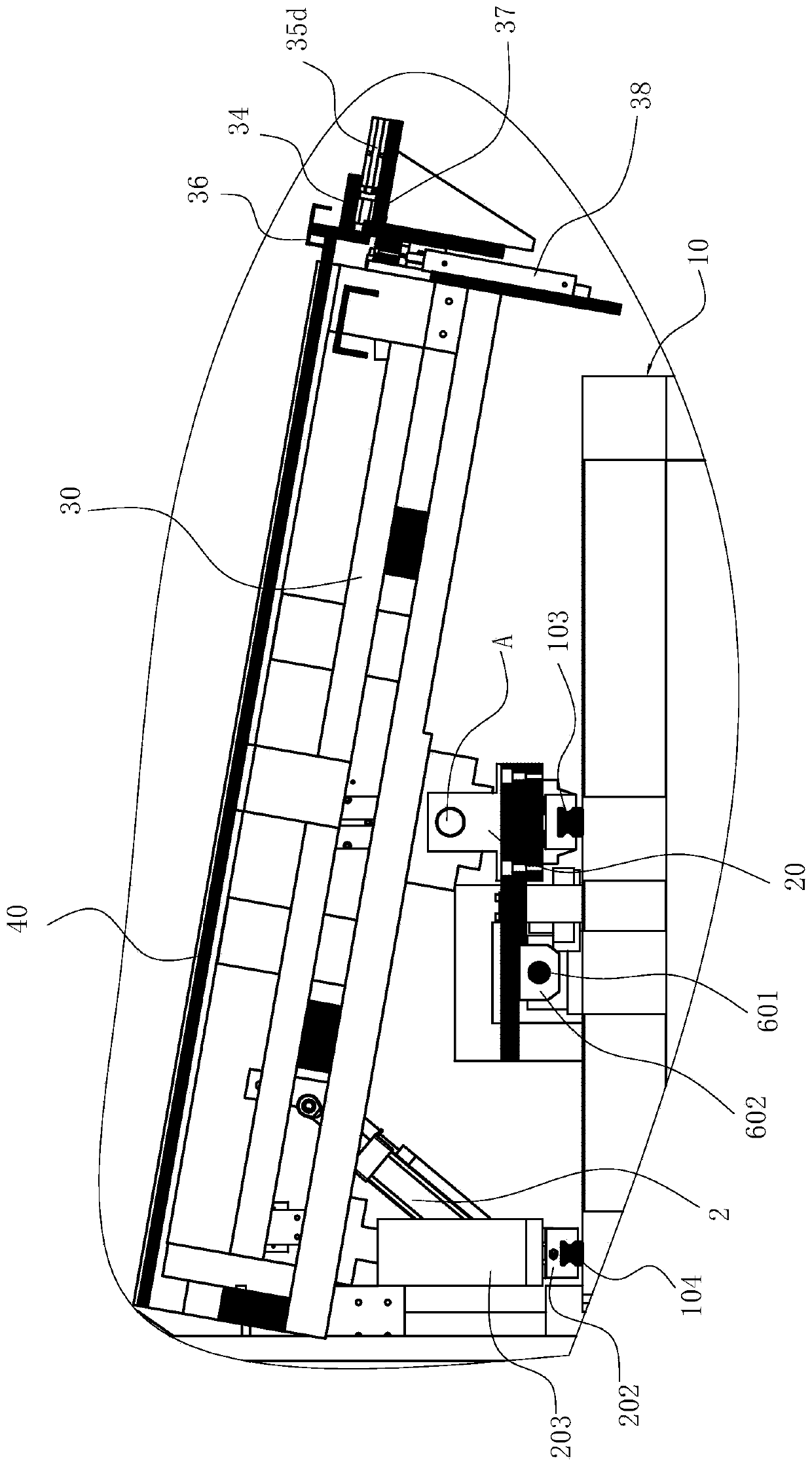

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0045] This slice machine can be used in occasions where slices need to be sorted in different industries. For the convenience of description, the chip arrangement machine in this embodiment is applied in the electroplating industry. The following material sheets are steel sheets, and the material sheets are aluminum sheets. The steel sheets need to be arranged on the aluminum sheets in sequence before electroplating to ensure the electroplating quality of the surface.

[0046] In the following description, it should be understood that the terms "left and right", "front and rear", "height", "length", "width", "thickness", "upper", "lower", "front", "rear" ", "Left", "Right", "Horizontal", "Top", "Bottom", "Inner", "Outer" and other indicated orientations or positional relationships are based on the orientations or positional relationships show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com