A bottle loading method and a bottle loading device

A bottle feeding and bottle body technology, applied in packaging, bottle packaging, transportation and packaging, etc., can solve problems such as broken bottles, crowded bottles, and unsmooth pushing of bottles, so as to prevent broken bottles and ensure orderliness , easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

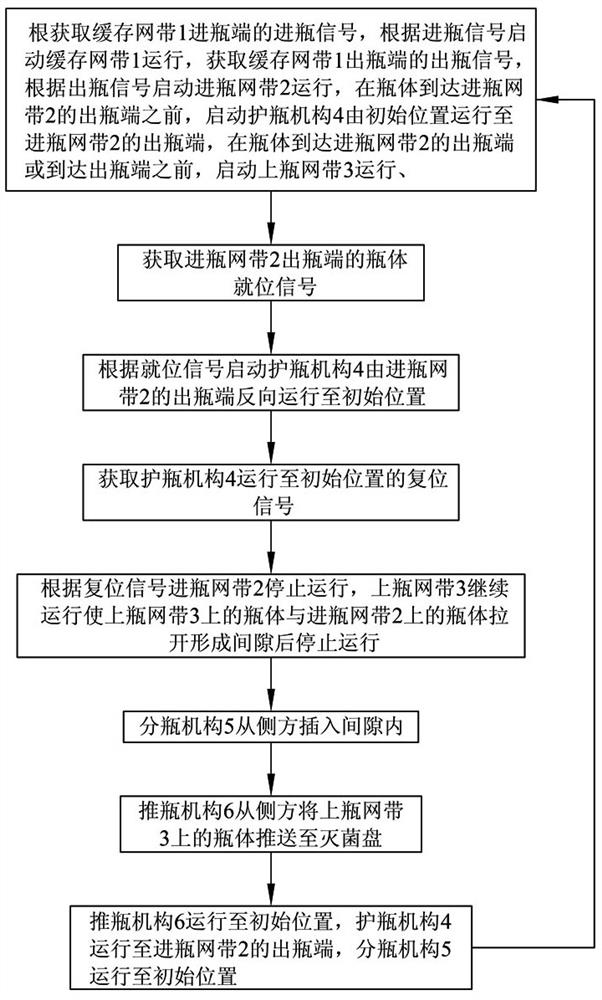

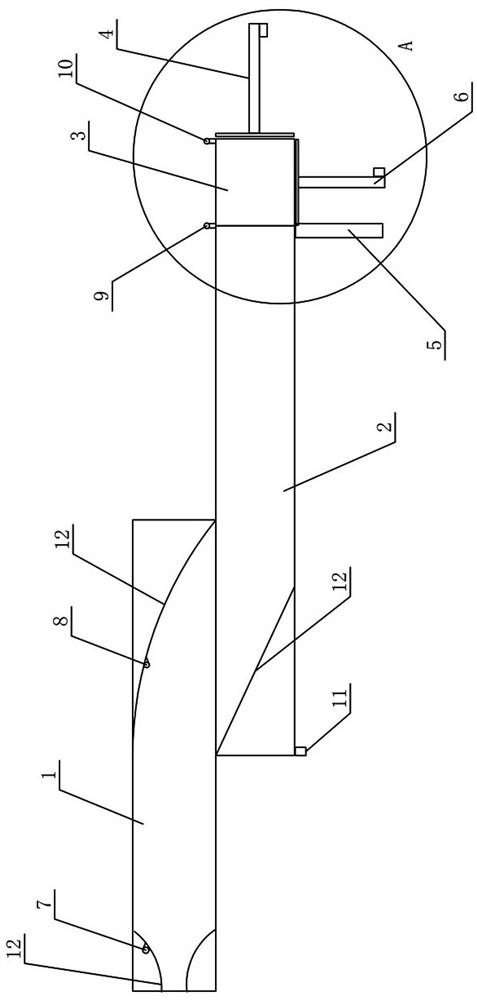

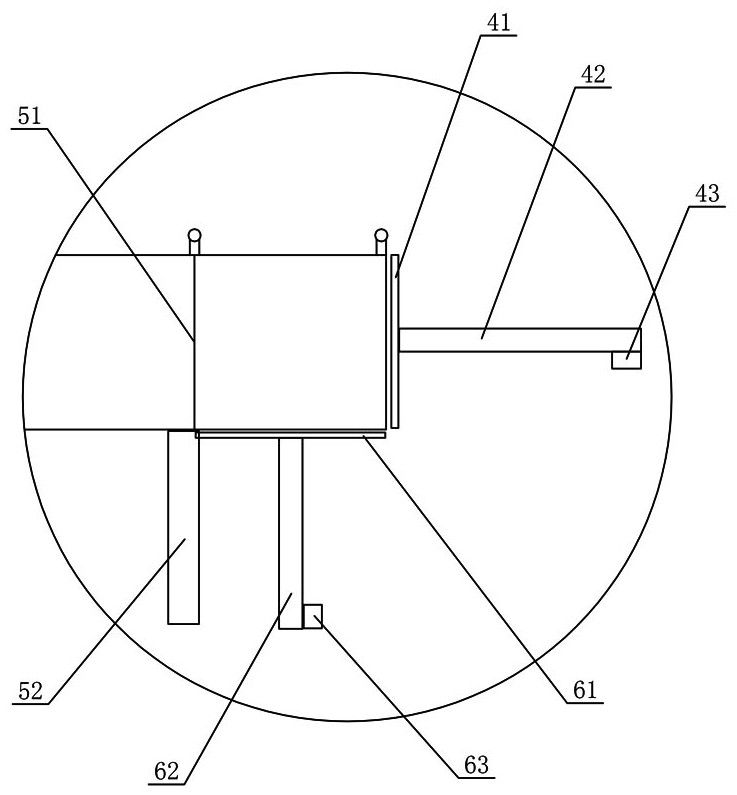

[0034] Figure 1 to Figure 3 A kind of embodiment of the bottle-going method of the present invention is shown, comprises the following steps:

[0035] S1: Obtain the bottle-input signal of the bottle-inlet end of the buffer network belt 1, start the operation of the buffer network belt 1 according to the bottle-in signal, obtain the bottle-out signal of the bottle-out end of the buffer network belt 1, start the operation of the bottle-in mesh belt 2 according to the bottle-out signal, and Before the bottle body reaches the bottle outlet end of the bottle inlet mesh belt 2, start the bottle protection mechanism 4 to move from the initial position to the bottle outlet end of the bottle inlet mesh belt 2, and when the bottle body reaches the bottle outlet end of the bottle inlet mesh belt 2 or reaches the outlet end Before the bottle e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com