Wood plate pressing fit device for composite wood plate

A technology for pressing a device and a composite wood board, which is applied in the field of furniture processing and can solve the problems of complicated operation of the device and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

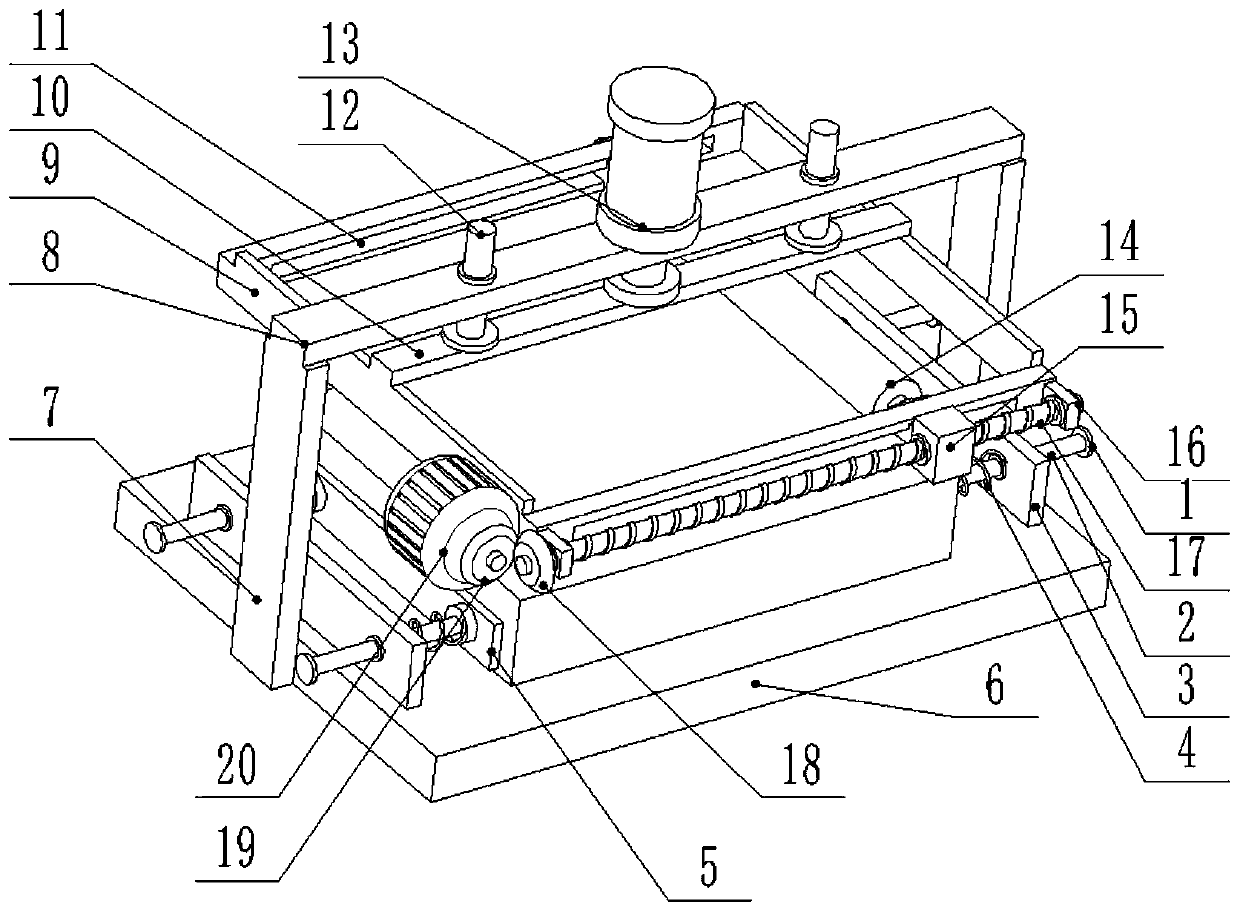

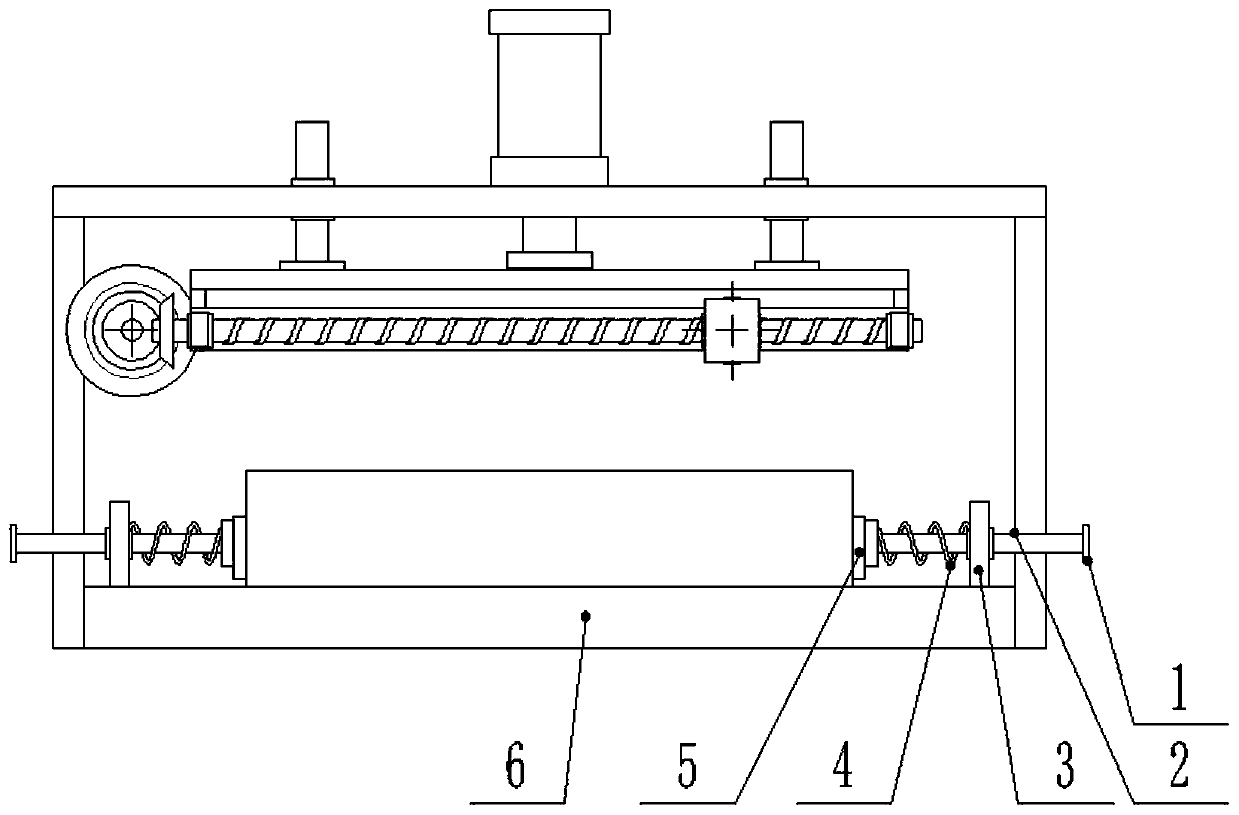

[0022] see Figure 1-3 , a kind of plank pressing device for composite planks, comprising a base plate 6, the left and right ends of the base plate 6 are provided with brackets 7, the upper end of the bracket 7 is provided with a horizontal plate 8, the middle part of the horizontal plate 8 is provided with a cylinder 13, and the piston of the cylinder 13 The rod is fixedly connected to the pressure plate 10, the left and right sides of the pressure plate 10 are connected to the fixed frame 9, the front and rear sides of the fixed frame 9 are provided with chute 11, the chute 11 is slidably connected to the slider 15, and the middle part of the slider 15 is rotated to connect with the pressure roller 14. The left side of the fixed frame 9 is provided with a drive motor 20, the output shaft of the drive motor 20 is fixedly connected to the first bevel gear 19, the first bevel gear 19 is engaged with the second bevel gear 18, and the second bevel gear 18 is fixedly connected to ...

Embodiment 2

[0025] The other content of this embodiment is the same as that of Embodiment 1, except that guide rods 12 are provided on the left and right sides of the upper surface of the pressing plate 10 , and the middle part of the guide rod 12 is slidably connected to the horizontal plate 8 . In order to further ensure that the up and down movement of the pressure plate 10 is more stable, guide rods 12 are provided on the left and right sides of the pressure plate 10, thereby restricting the movement of the pressure plate 10 through the guide rods 12, so that the pressure plate 10 can move up and down stably, ensuring the normal operation of the entire device use.

[0026] In the implementation process of the present invention, the cylinder 13 is first started, and the piston rod of the cylinder 13 shrinks, thereby driving the entire fixed frame 9 to move upwards. At this time, the clamping plates 5 are separated from the left and right sides, and the composite wood boards that need to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com