Method, device, equipment and storage medium for controlling laser galvanometer welding

A laser galvanometer and control instruction technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of low efficiency of welding program debugging, achieve the effect of improving efficiency and reducing error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to make the objectives, technical solutions and advantages of the present application more clear, the present application will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present application, but not to limit the present application.

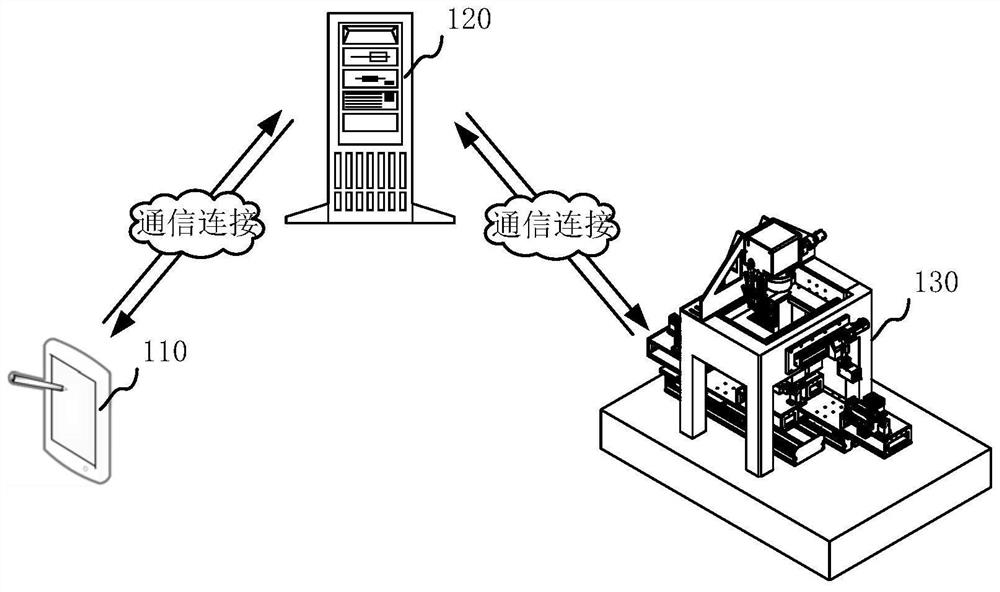

[0067] figure 1 It is an application environment diagram of the method for controlling laser galvanometer welding in one embodiment. refer to figure 1 , the method for controlling laser galvanometer welding is applied to a system for controlling laser galvanometer welding. The system for controlling laser galvanometer welding includes a terminal 110 , a programmable controller 120 and a laser galvanometer welding device 130 . The terminal 110 and the laser galvanometer welding equipment 130 are communicatively connected through the programmable controller 120 . The terminal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com