Control method, equipment and storage medium of double-valve dispensing device

A control method and valve point technology, which can be applied to devices and coatings that apply liquid to the surface, which can solve the problems of poor dispensing flexibility, low adaptability, and inability to ensure the accuracy of the double valve position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0057] It should be noted that the two valves of the existing double valve dispensing have a fixed spacing and cannot be adjusted. As a result, when dispensing glue, the dispensing spacing is fixed when matching the dispensing product, making the dispensing flexibility poor. , the adaptability is low, and the distance between the double valves driven by an adjustable motor can be adjusted. However, in the process of adjusting the distance between the two valves by the motor, it is manually judged whether the position of the double valve matches the actual dispensing position. , resulting in the inability to ensure that the position accuracy of the adjusted double valve can meet the production demand.

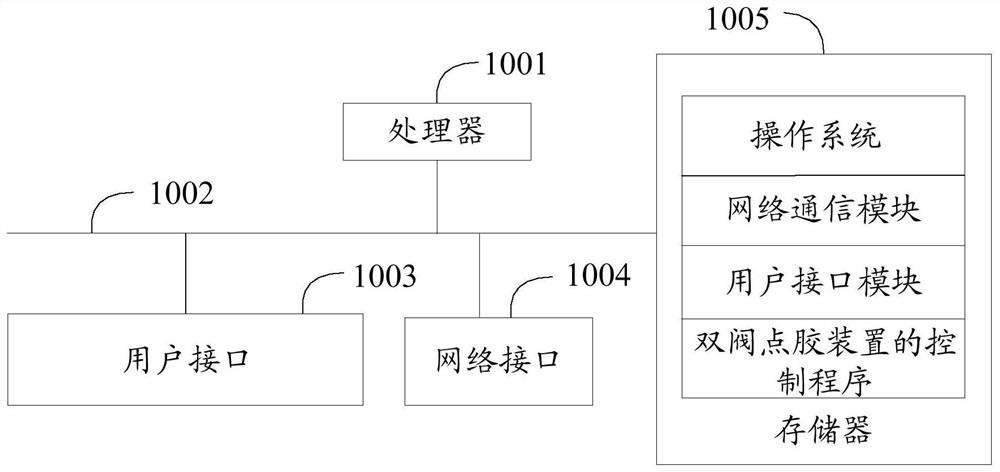

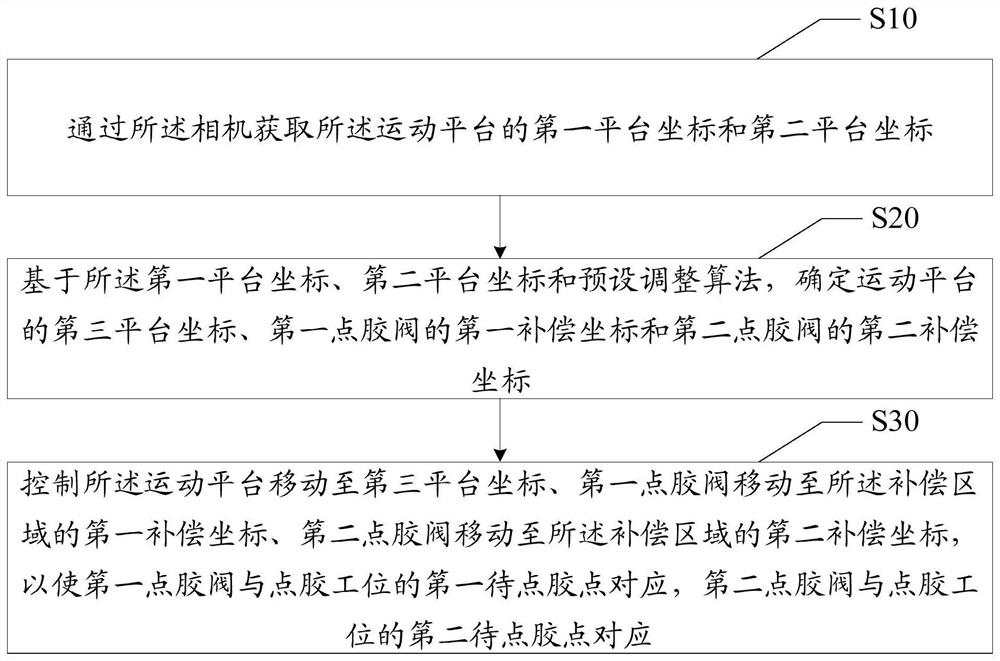

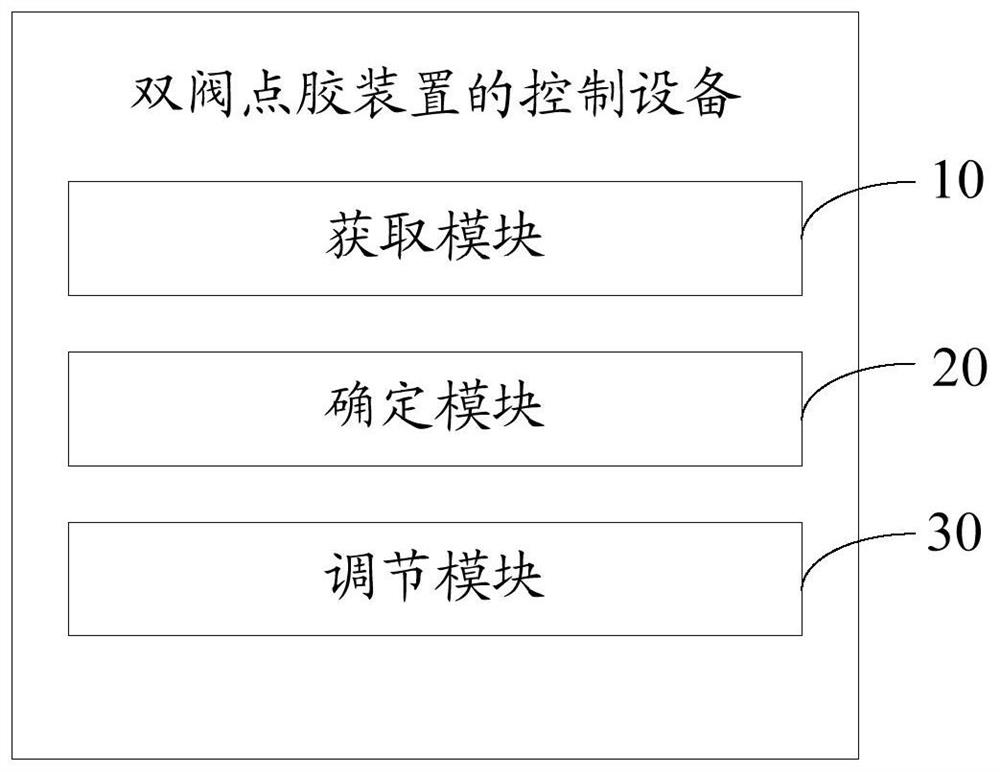

[0058] Based on the above defects, the present invention provides a control device for a double-valve dispensing devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com