Extrusion-type camellia fruit huller for grain and oil processing

An extruded camellia fruit technology, which is applied in the field of extruded camellia fruit shellers for grain and oil processing, can solve problems such as unfavorable and stable production, long time-consuming cracking, and large weather impact, so as to save manpower and stabilize production , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

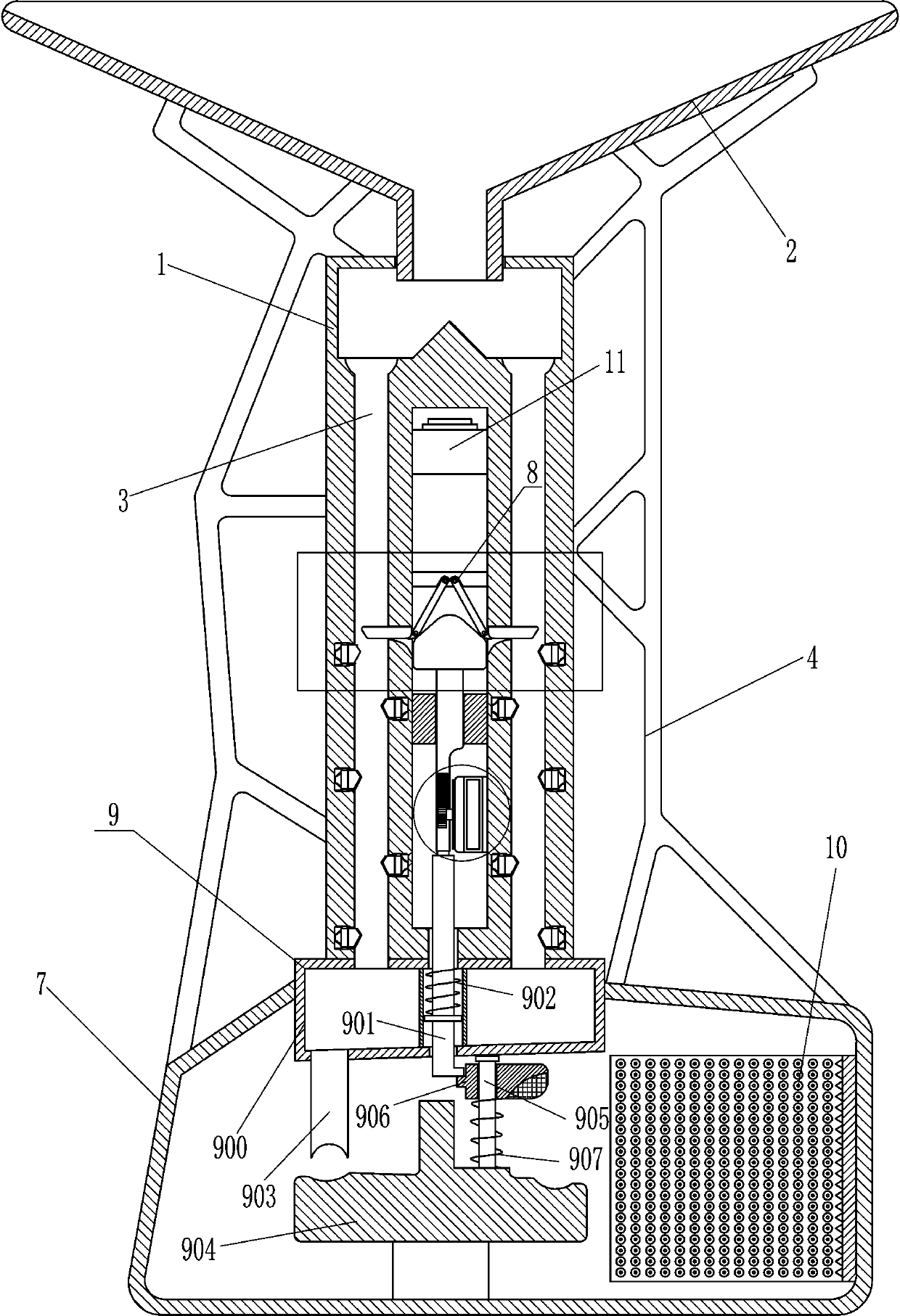

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] first implementation

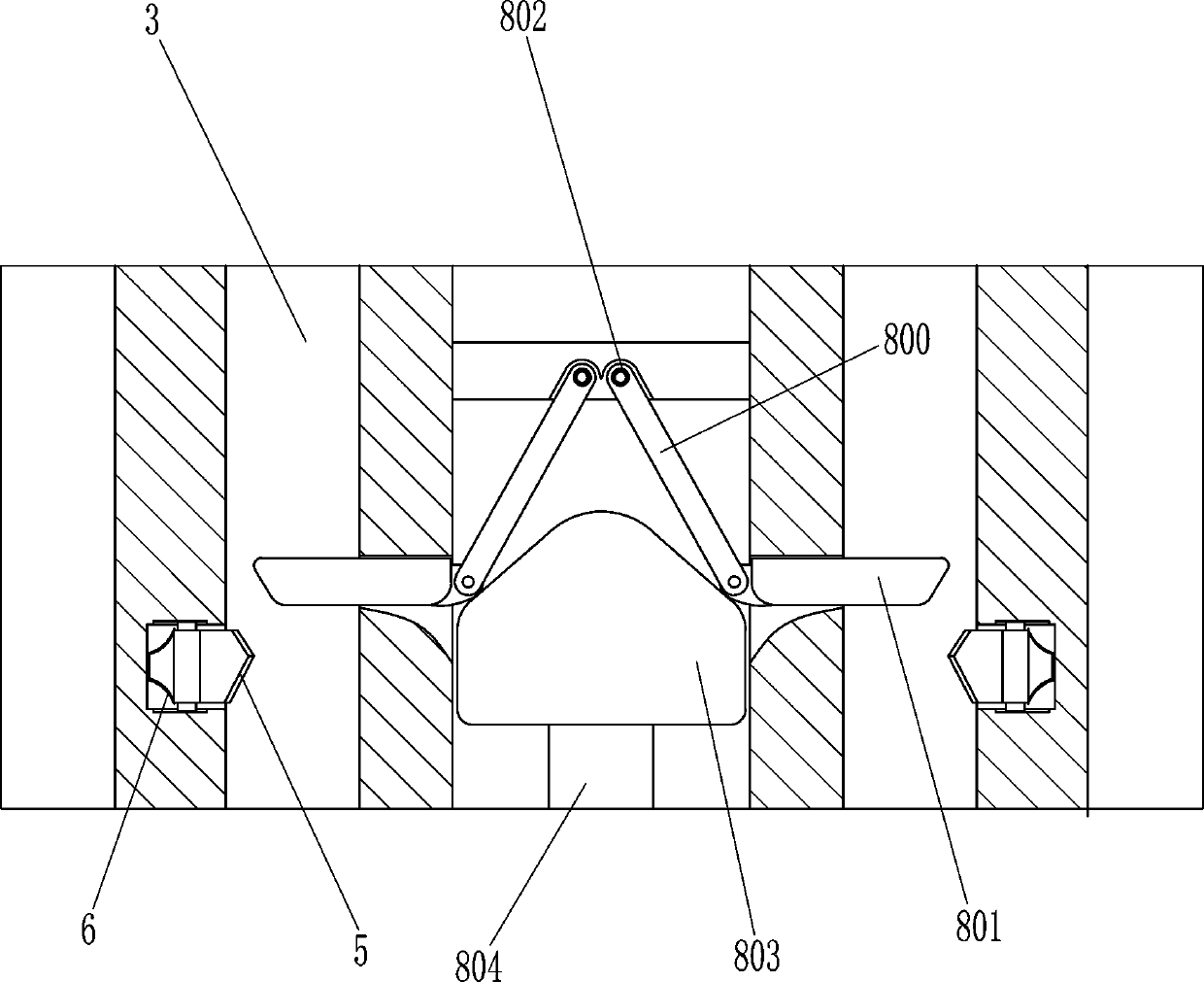

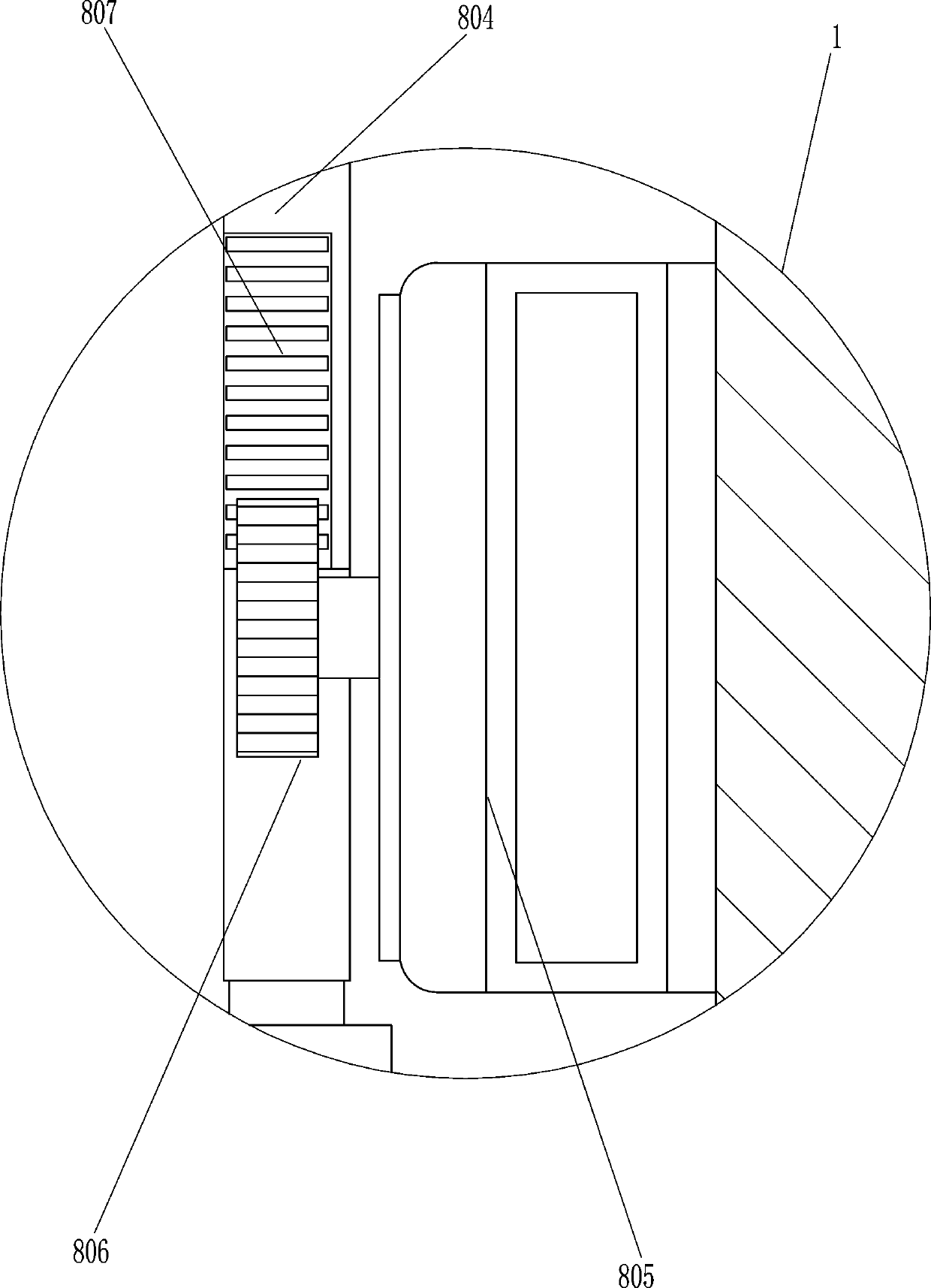

[0018] see Figure 1-2 , an extruding camellia sheller for grain and oil processing, including a hollow cylinder 1 and a hopper 2, the top of the hollow cylinder 1 is provided with a hopper 2, and also includes a bracket 4, an incision blade 5, a shrapnel 6, and a bottom frame 7 and the extruding device 8, the hollow cylinder 1 is evenly spaced along the circumferential direction with a plurality of through grooves 3, the through grooves 3 are arranged vertically, a bracket 4 is connected between the hollow cylinder 1 and the outside of the hopper 2, and the bracket 4 passes through The way of welding connection is connected with the hollow cylinder 1 and the hopper 2, the bottom of the support 4 is connected with the bottom frame 7, and the inner two walls of each channel 3 are evenly spaced and slidingly provided with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com