Safety sensing system suitable for oil-immersed distribution transformer

A technology for distribution transformers and sensing systems, applied in the field of safety sensing systems, can solve problems such as joint losses, complex transformer structures, and transformer operation failures, and achieve the effects of improving maintenance efficiency, facilitating technical support, and ensuring work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

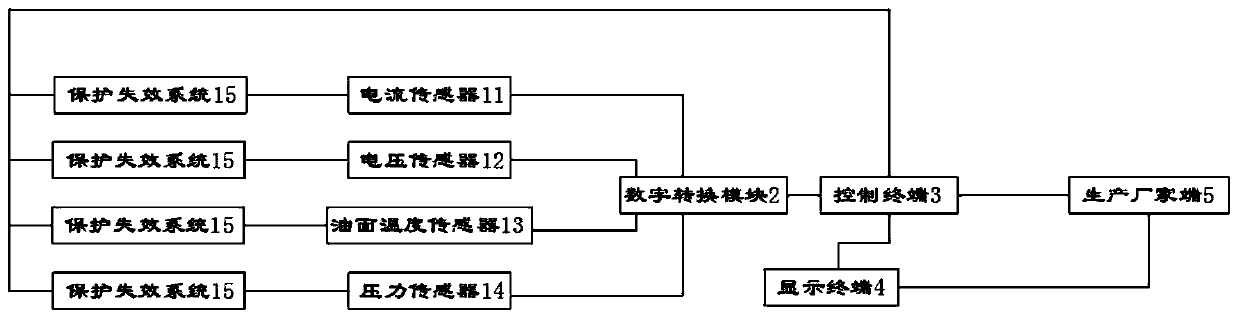

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0025] The invention provides a safety perception system suitable for oil-immersed distribution transformers. Its working principle is to detect various data when the transformer is working through a measurement module, use an intelligent terminal to analyze the data transmitted by the measurement module, and communicate with the storage The comparison of the reference data, using the analysis structure of the customer terminal to receive the transmission of the intelligent terminal, is convenient for the staff to know the current working condition of the transformer at any time, so as to know the working status of the current transformer in time, reduce the working pressure of the staff and ensure the safe use of the transformer the goal of.

[0026] The present invention wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com