Seal for sealing a peripheral gap between two machine components

A technology of machine parts and seals, which is applied in the field of seals used to seal the circumferential gap between two machine parts, can solve problems such as blocking auxiliary sealing systems, reduce complexity, reduce subsequent processing, and reduce testing The effect of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

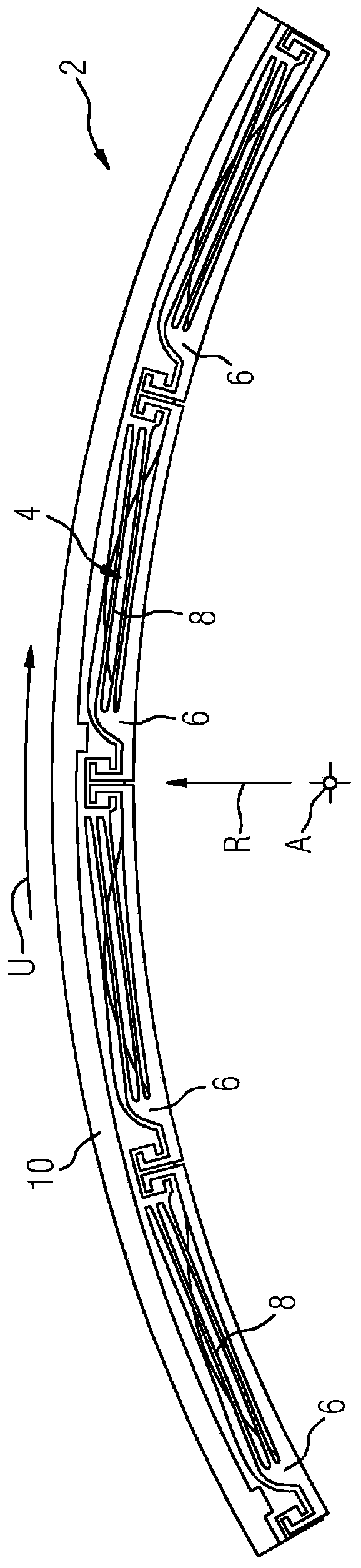

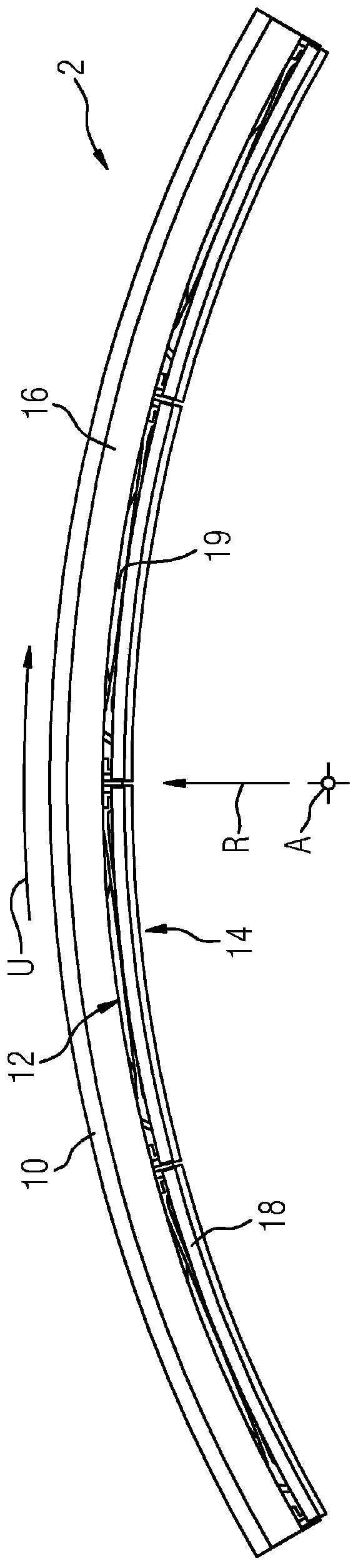

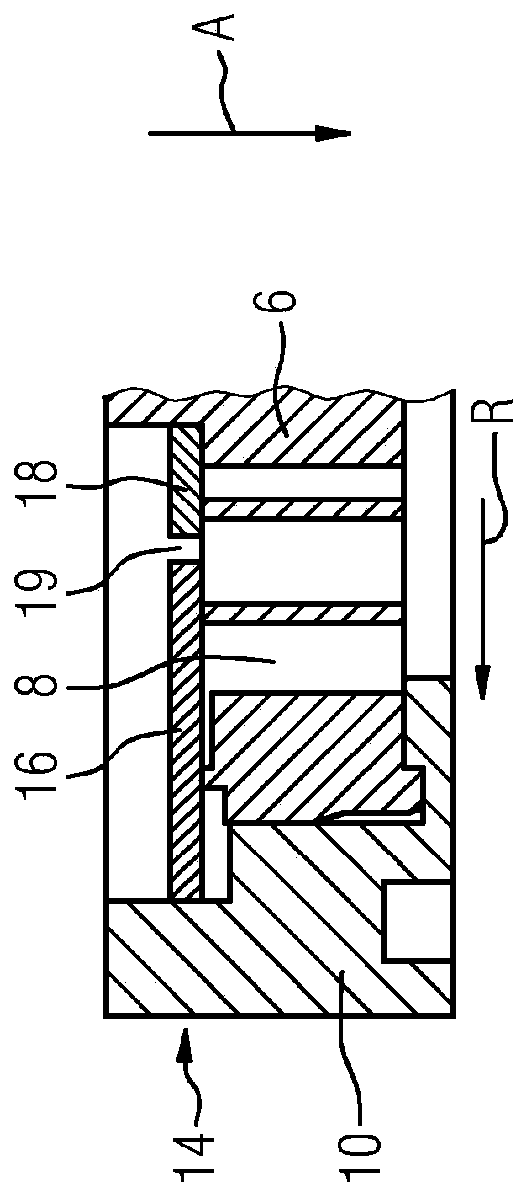

[0033] figure 1 A part of a seal 2 is shown, which is used to seal a circumferential gap between two machine parts (not shown here in detail), which can rotate axially relative to each other. The axial direction is symbolically identified by point A, which is intended to represent the center of the circle formed by the complete seal 2 , although the pitch ratio is not maintained in the figure. figure 1 Radial R and circumferential U are also shown.

[0034] The seal 2 comprises a main seal 4 having a plurality of so-called shoes 6 for creating a contact-free seal between machine parts. To enable this function, the boots 6 are each elastically mounted on the carrier 10 via a spring element 8 . The shoe 6 is supported on a machine part by the bracket 10 so that radial movement of the shoe can be made in response to fluid pressure applied to the shoe 6 .

[0035] Furthermore, the seal 2 comprises a layered auxiliary seal 12 which seals the spring element 8 in the axial direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com