Self-lubricating bearing

A self-lubricating bearing and bearing seat technology, used in bearing cooling, bearing components, shafts and bearings, etc., can solve problems such as easy burning of tiles, and achieve the effect of sufficient lubrication and heat dissipation and cooling capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

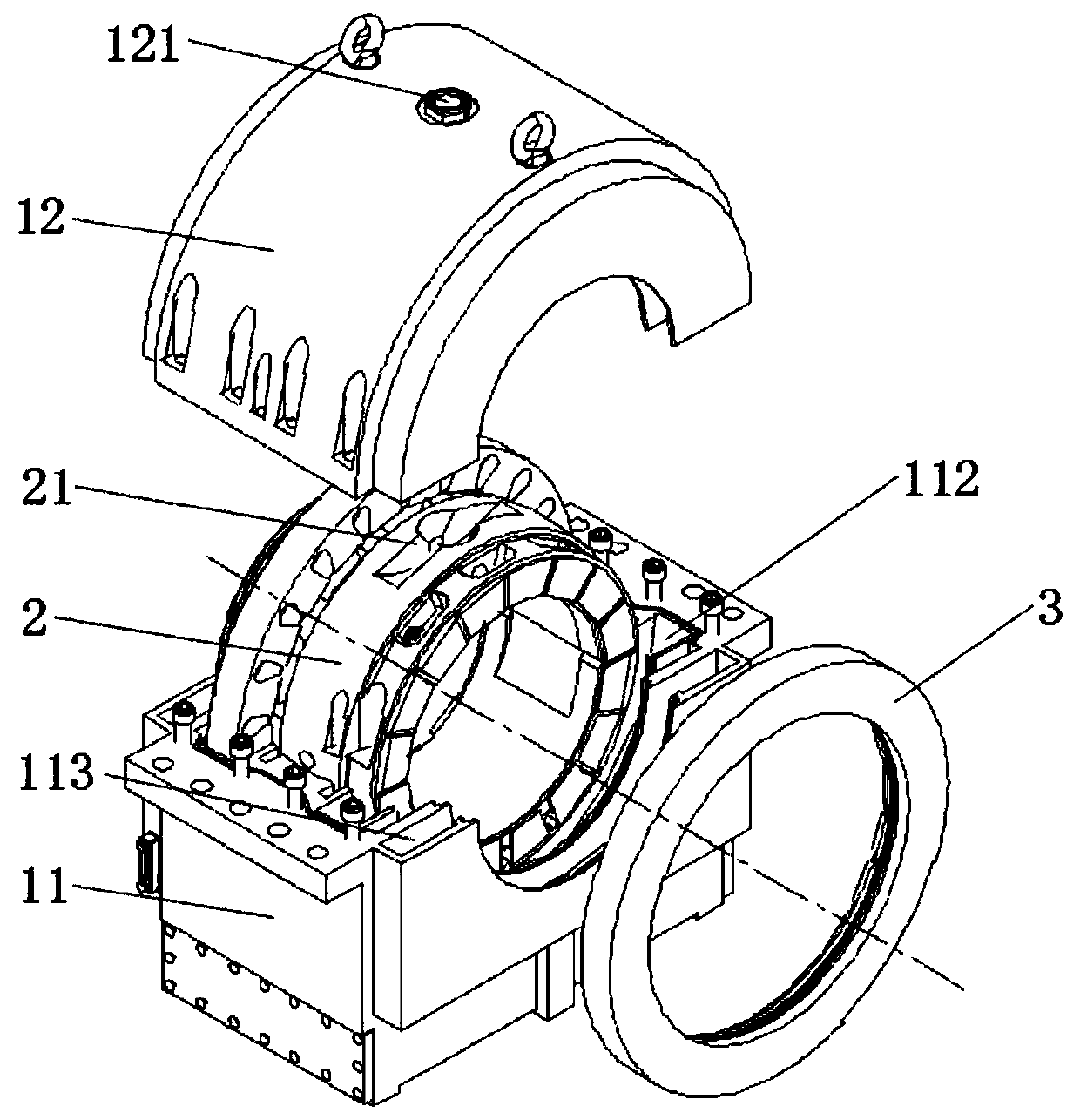

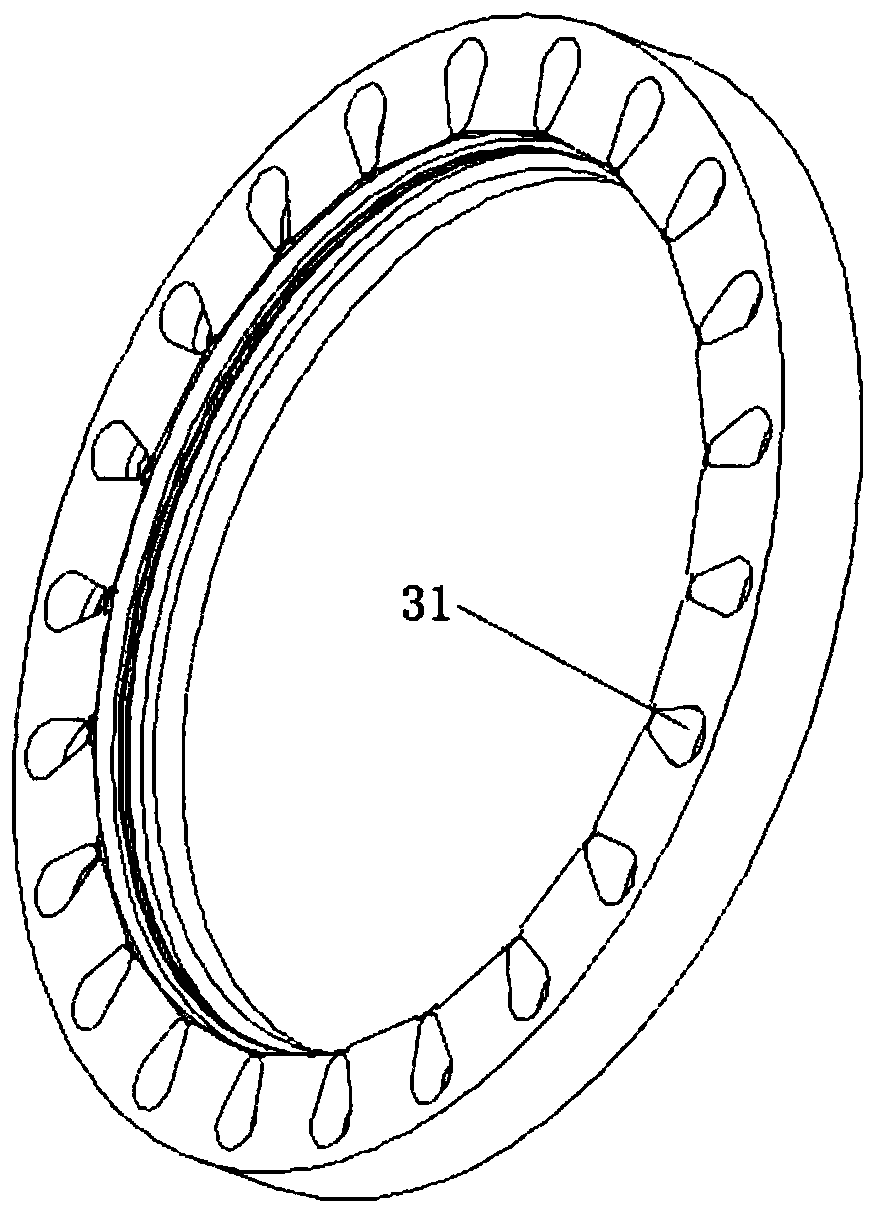

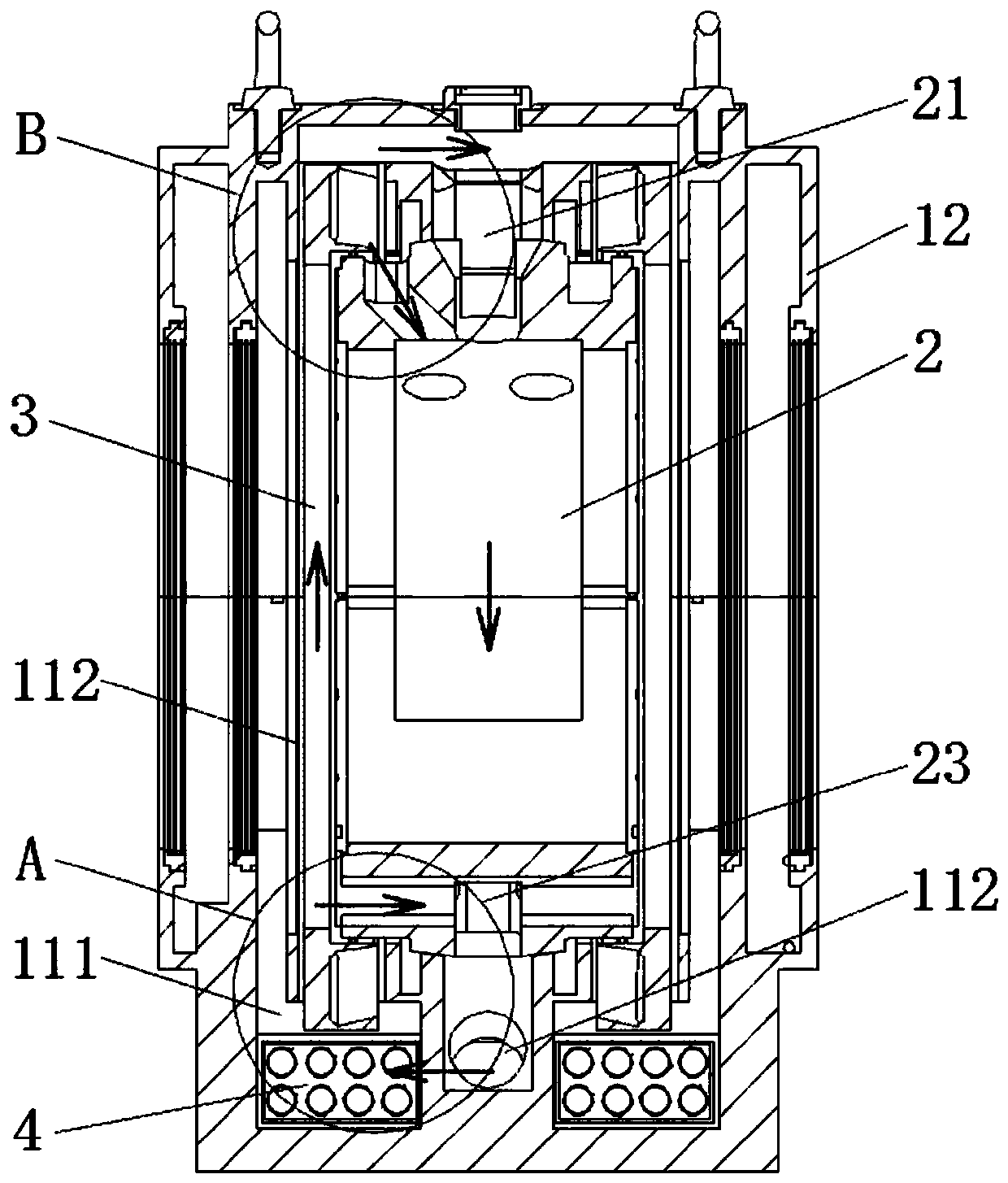

[0045] A self-lubricating bearing. The self-lubricating bearing includes a housing 1, a bearing bush 2, an oil thrower 3 and a radiator 4. The bearing bush 2 is located in the housing 1, and the lower part of the housing 1 is provided with an oil storage chamber 111 relative to the bearing bush 2. Lubricating oil is placed in the oil storage chamber 111; the oil thrower 3 is located in the housing 1, the oil thrower 3 corresponds to the bearing bush 2, and the lower part of the oil thrower 3 is located in the oil storage chamber 111.

[0046] Housing 1, housing 1 is divided into bearing housing 11 and bearing cover 12, bearing housing 11 is provided with oil storage cavity 111 and oil throwing pan 3 cavities, oil throwing pan 3 cavities are located above oil storage cavity 111, and oil throwing pan The 3 cavities are connected to the oil storage chamber 111; the bearing cover 12 is provided with an oil receiving hole 121 and an oil receiving cavity 122, wherein the oil receivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com