Dexrazoxane preparation method

A technology of dextropropylimine and amides, which is applied in the field of preparation of dextropropylimine, can solve the problems of complex synthesis route and harsh reaction conditions of dextropropylimine, achieve high application value and development prospect, easy industrialization, and simplify The effect of process operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

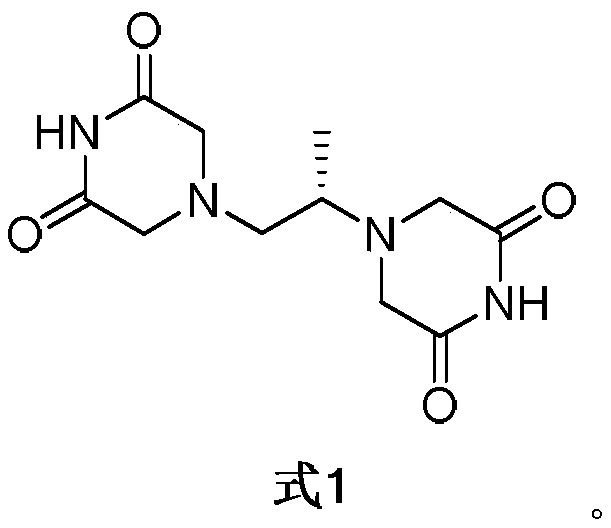

[0032] Preparation of dextropropanimine

[0033] Add (S)-1,2-diaminopropane-tetraacetic acid (10g) into a reaction flask equipped with a water separator, add N,N-dimethylformamide (50ml), ammonium formate (20.6g), Heat to 150°C, separate the reflux from the water separator, stir for 10 hours, concentrate, add 20 ml of purified water and stir for 0.5 hours, filter, and dry to obtain 7.1 g of crude dextropropylimine (yield 81%), HPLC purity 99.2 %.

[0034] Add the crude product of dextropropylimine to the reaction flask, add N,N-dimethylformamide (14ml) and heat to 80°C, stir and dissolve, add absolute ethanol (64ml), cool down to 20°C-30°C for crystallization Stir for 1 hour, filter and dry to obtain 6.2 g (yield 87%), HPLC purity 99.83%.

Embodiment 2

[0036] Preparation of dextropropanimine

[0037] Add (S)-1,2-diaminopropane-tetraacetic acid (120g) into a reaction flask equipped with a water separator, add N,N-dimethylformamide (480ml), ammonium formate (240g), and heat To 150°C, the water separator separated the reflux, stirred for 10 hours, concentrated, added 360ml of purified water and stirred for 0.5 hours, filtered, and dried to obtain 83g of crude dextranimine (yield 81%), HPLC purity 98.9%.

[0038] Add the crude product of dextropropylimine to the reaction flask, add N,N-dimethylformamide (208ml) and heat to 80°C, stir and dissolve, add absolute ethanol (624ml), cool down to 20°C-30°C for crystallization Stir for 1 hour, filter and dry to obtain 70 g (yield 84%), HPLC purity 99.72%.

Embodiment 3

[0040] Preparation of dextropropanimine

[0041] Add (S)-1,2-diaminopropane-tetraacetic acid (15g) into a reaction flask equipped with a water separator, add N,N-dimethylacetamide (60ml), ammonium formate (25g), and heat To 155°C, the water separator separated the reflux, stirred for 18 hours, concentrated under reduced pressure, added 45ml of purified water and stirred for 0.5 hours, filtered and dried to obtain 10.3g of the target product (yield 79%), HPLC purity 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com